Backlight module preparation process and backlight module

A technology of backlight module and preparation process, which is applied to mirrors, instruments, identification devices, etc., can solve the problems of poor dark line elimination effect, etc., and achieve the effects of good adjustability, high controllability and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

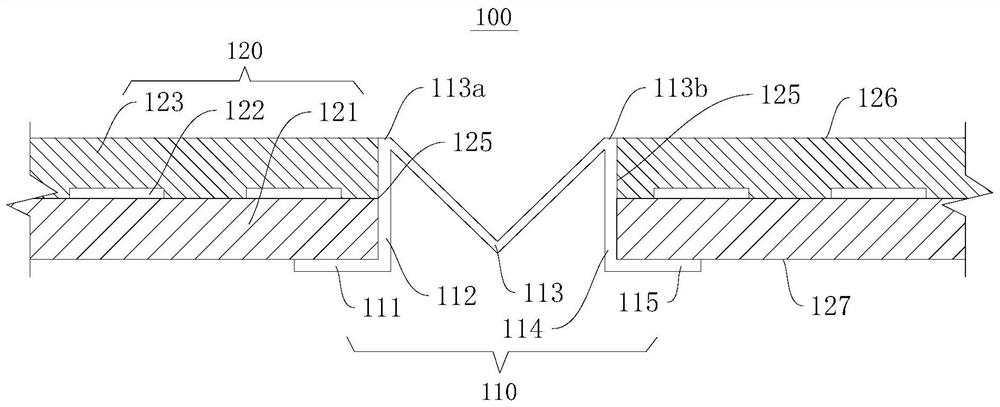

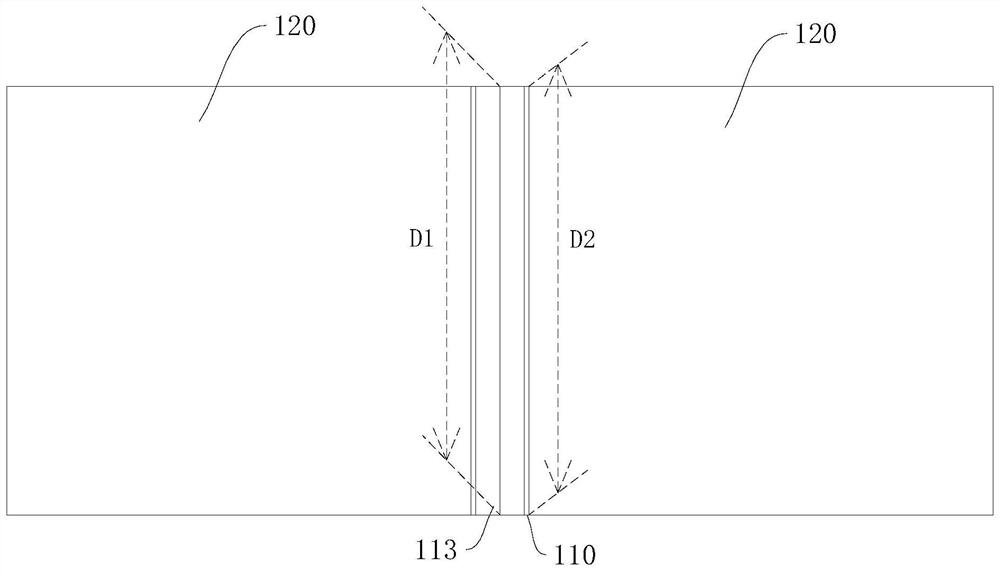

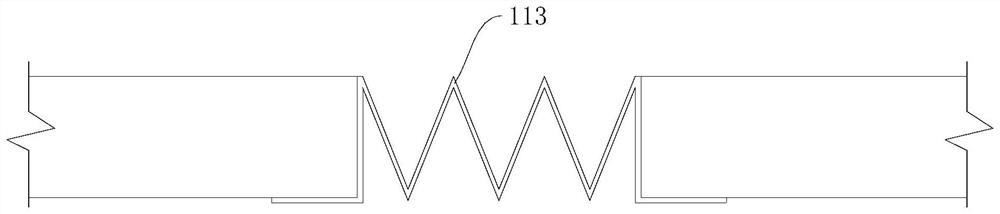

[0047] Please refer to figure 1 and figure 2 , this embodiment provides a backlight module 100 , the backlight module 100 is formed by splicing a plurality of light emitting modules 120 . The backlight module 100 includes: a reflective material 110 and a light emitting module 120 . The light emitting module 120 defines a light emitting surface 126 and a backlight surface 127 opposite to each other, and a side surface 125 connecting the light emitting surface 126 and the backlight surface 127 .

[0048] Wherein, the light-emitting modules 120 are spliced together, and there is a seam between the light-emitting modules 120. The reflective material 110 is structured in a layered shape and is used to block the seam between the light-emitting modules 120. The reflective material 110 is arranged on two adjacent light-emitting modules. between the groups 120 and connected to the backlight surface 127 and / or the side surface 125 of the light emitting module 120 , so as to cover t...

Embodiment 2

[0065] Please refer to Figure 8 , this embodiment provides a backlight module 200 , the backlight module 200 is formed by splicing a plurality of light emitting modules 230 . The backlight module 200 includes: a backplane 210 , a reflective material 220 , a light emitting module 230 and a support 240 . The light emitting module 230 defines a light emitting surface 234 and a backlight surface 235 opposite to each other, and a side surface 236 connecting the light emitting surface 234 and the backlight surface 235 .

[0066] The support 240 is installed on the backplane 210, and the light-emitting module 230 is also installed on the backplane 210 and spliced on the backplane 210. The support 240 is arranged between two adjacent light-emitting modules 230, and the reflective material 220 is covered on the support. 240 is close to the side of the light-emitting surface 126 of the light-emitting module 230 to cover the seams between the light-emitting modules 230 .

[0067] Wi...

Embodiment 3

[0083] Please refer to Figure 10 , this embodiment provides a backlight module 300. Compared with the backlight module 100 in Embodiment 1, the difference is that: the two adjacent light-emitting modules 310 in the backlight module 300 are provided with reflective materials 320. In a light-emitting module 310 , the reflective material 320 is disposed between the substrate 311 and the optical protective adhesive layer 312 to connect the light-reflective material 320 to the light-emitting module 310 , and the reflective material 320 extends toward another light-emitting module 310 . The reflective material 320 of two adjacent light-emitting modules 310 partially overlaps in the seam of the two light-emitting modules 310 , so as to cover the seam of the two light-emitting modules 310 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com