Capping head fast to disassemble and assemble

A capping and fast technology, which is applied in the field of capping heads, can solve the problems of labor and time-consuming, reduce production efficiency, etc., and achieve the effect of improving production efficiency and quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

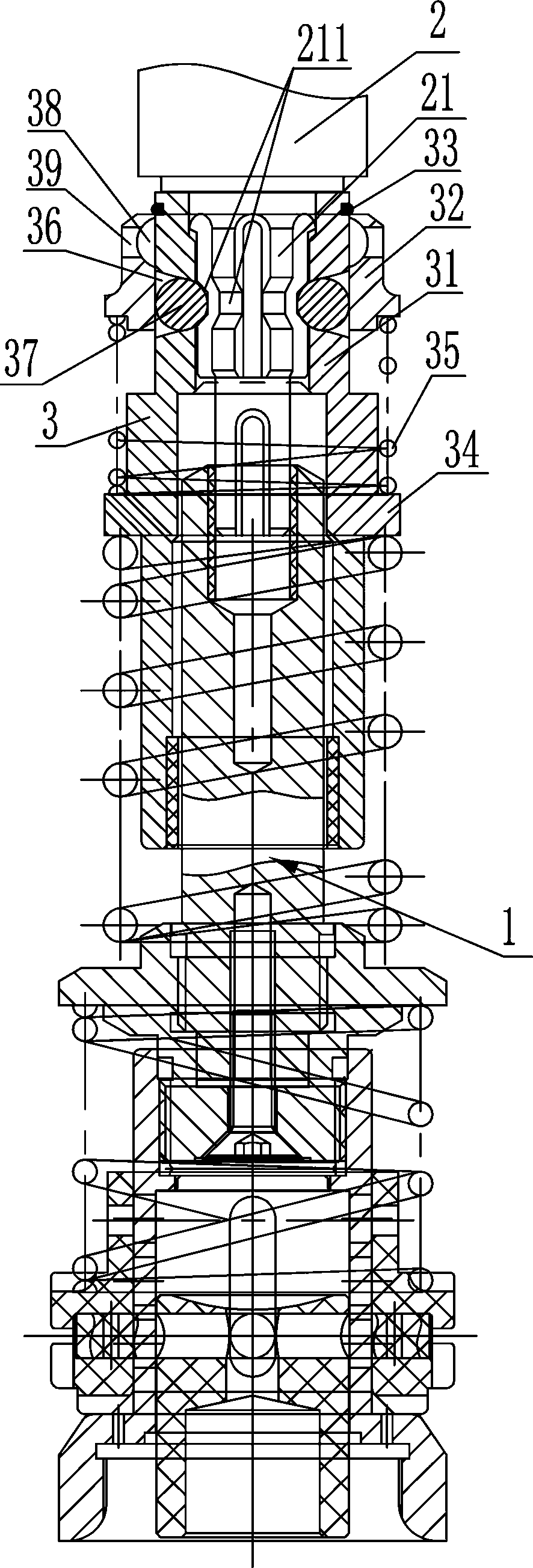

[0011] like figure 1 As shown, a capping head that can be quickly disassembled and assembled includes: a capping body 1 for capping, and a transmission for connecting to the connecting shaft 2 on the lifting device of the capping machine is provided on the top of the capping body 1. The connection mechanism, the structure of the transmission connection mechanism includes: a transmission shaft 3 arranged on the top of the screw cap body 1 and coaxial with the screw cap body 1, and a spline sleeve 31 coaxial with the transmission shaft 3 is arranged on the top end of the transmission shaft 3 , in the present embodiment, six teeth are evenly arranged in the spline sleeve 31, a sliding sleeve 32 is set on the spline sleeve 31, and a sliding sleeve 32 for blocking is arranged on the top side wall of the spline sleeve 31 The retaining ring 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com