Balance adjustment device of printing and dyeing wastewater treatment equipment

A technology for processing equipment, printing and dyeing wastewater, applied in textile industry wastewater treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve decolorization, dephosphorization, incomplete deodorization, mineral adsorbent adsorption There is no problem with the strength of the upper end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

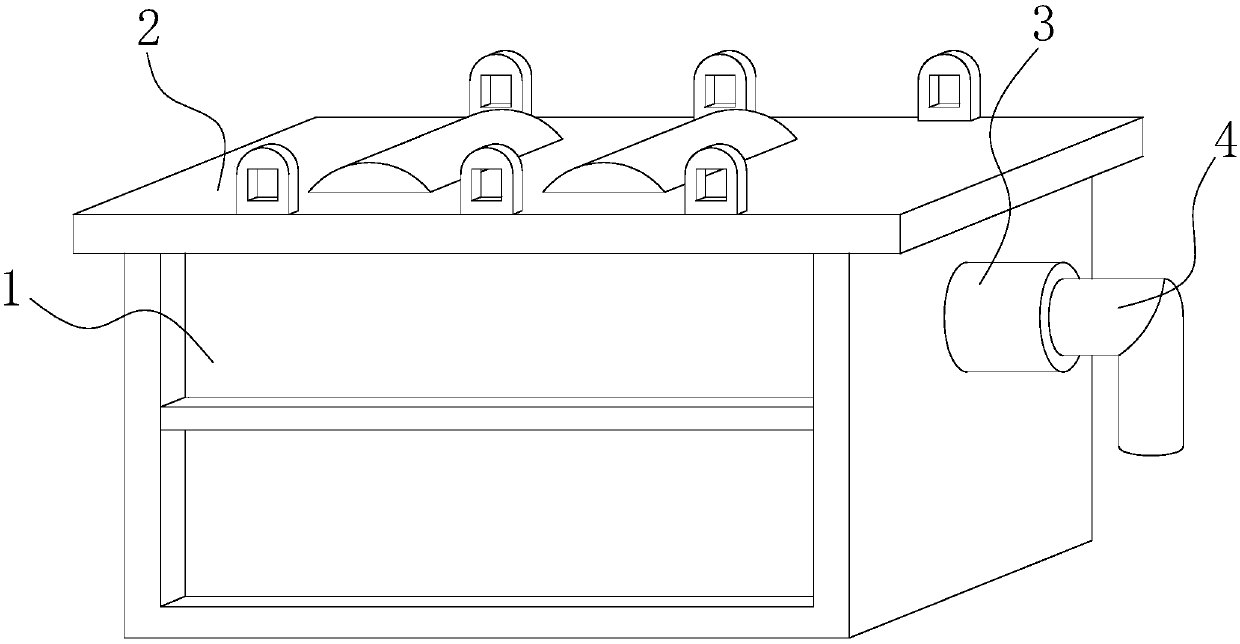

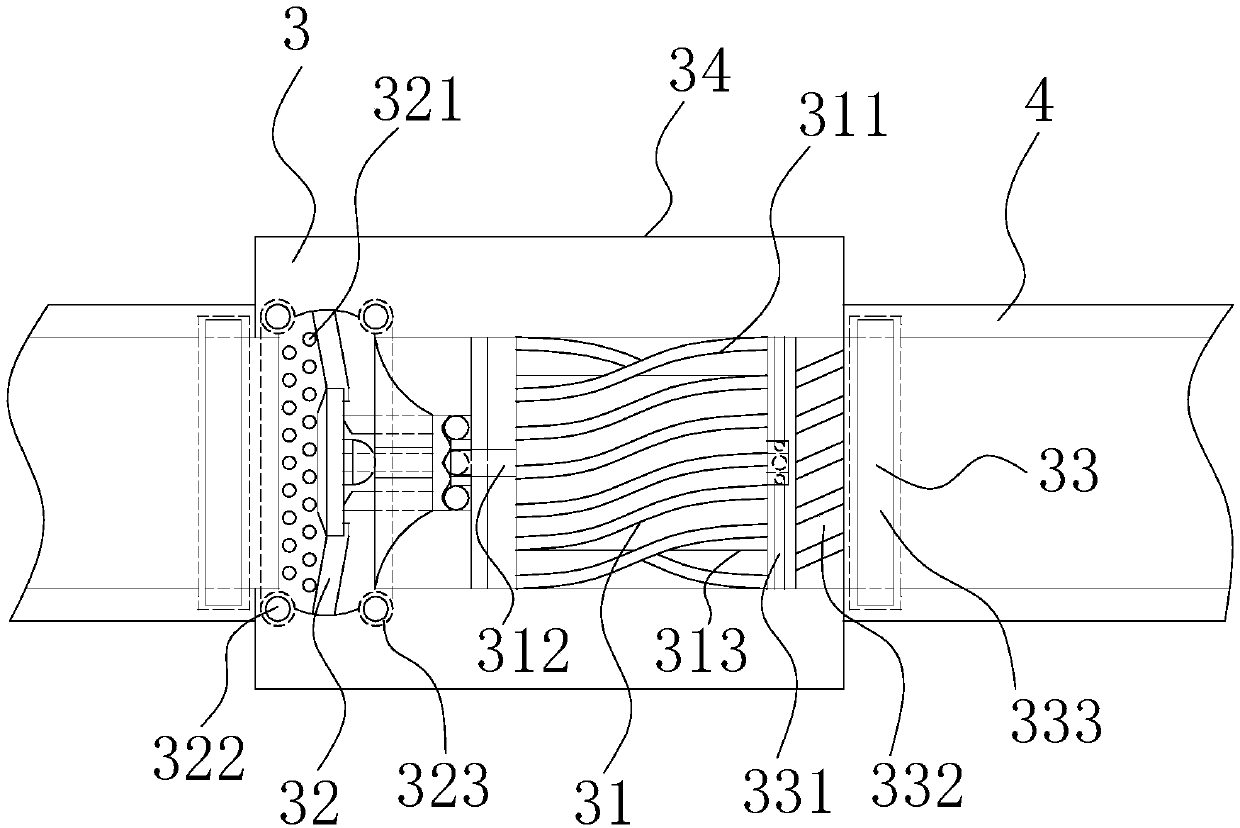

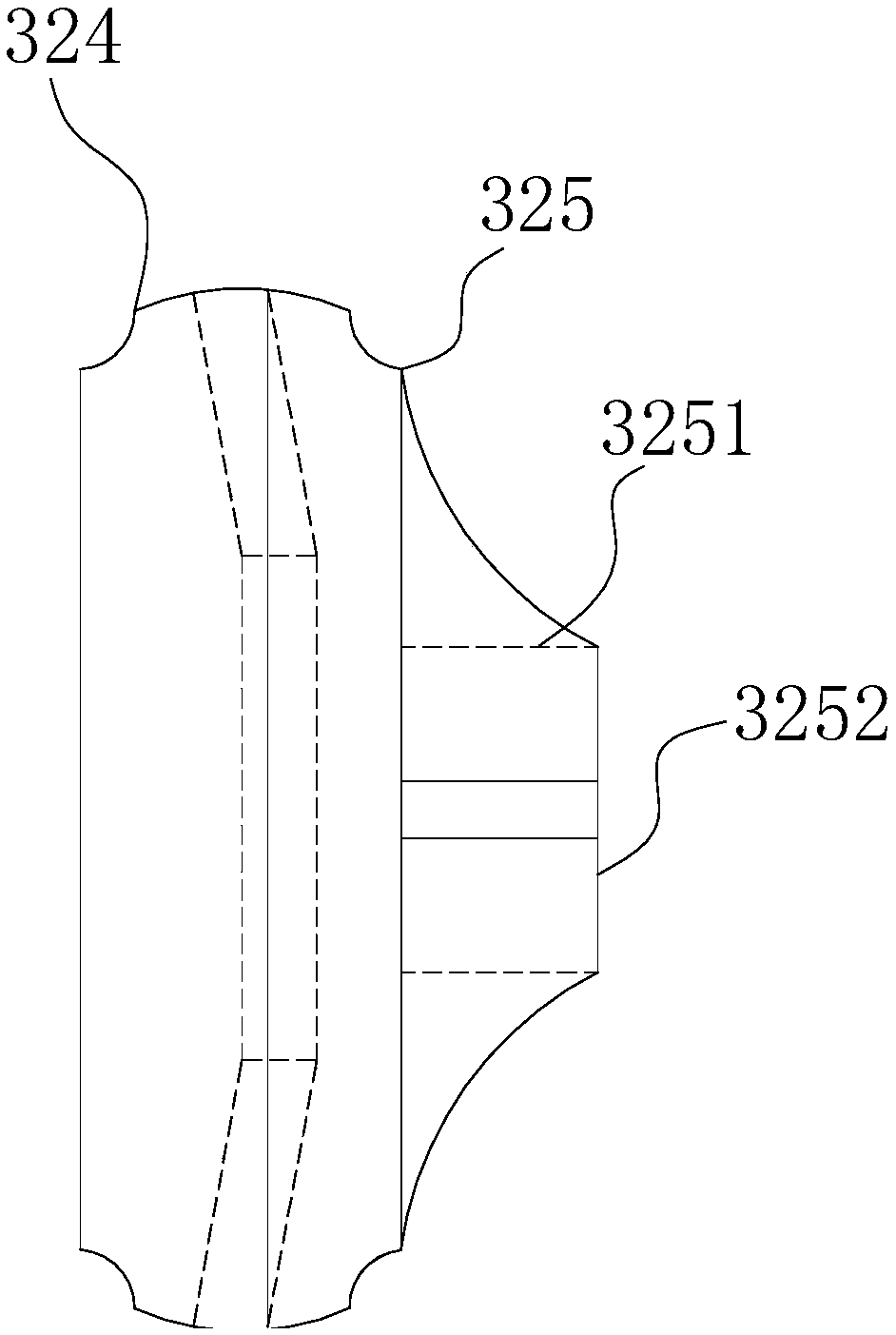

[0023] Such as Figure 1-Figure 8 As shown, the present invention provides a balancing device for printing and dyeing wastewater treatment equipment, the structure of which includes a chassis 1, an upper plywood 2, a balancing device 3, and an external pipe 4. The upper plywood 2 is horizontally installed on the upper surface of the chassis 1, The balancing device 3 runs through the right end face of the cabinet 1 horizontally, the external pipe 4 is horizontally embedded and installed inside the balancing device 3 , the external pipe 4 runs through the right end face of the cabinet 1, and the balancing device 3 It includes a blending mechanism 31, a circulating rolling mechanism 32, a directional drainage mechanism 33, and a casing 34. The blending mechanism 31 mechanically cooperates with the circulating rolling mechanism 32 through a connecting rod, and the circulating rolling mechanism 32 is installed horizontally inside the casing 34 , the directional drainage mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com