Engine cylinder deactivation mechanism

A technology of engine and sleeve, applied in the direction of engine components, engine control, machine/engine, etc., can solve the problem of high fuel-saving pressure, achieve the effect of reducing fuel consumption and realizing the fuel-saving effect of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

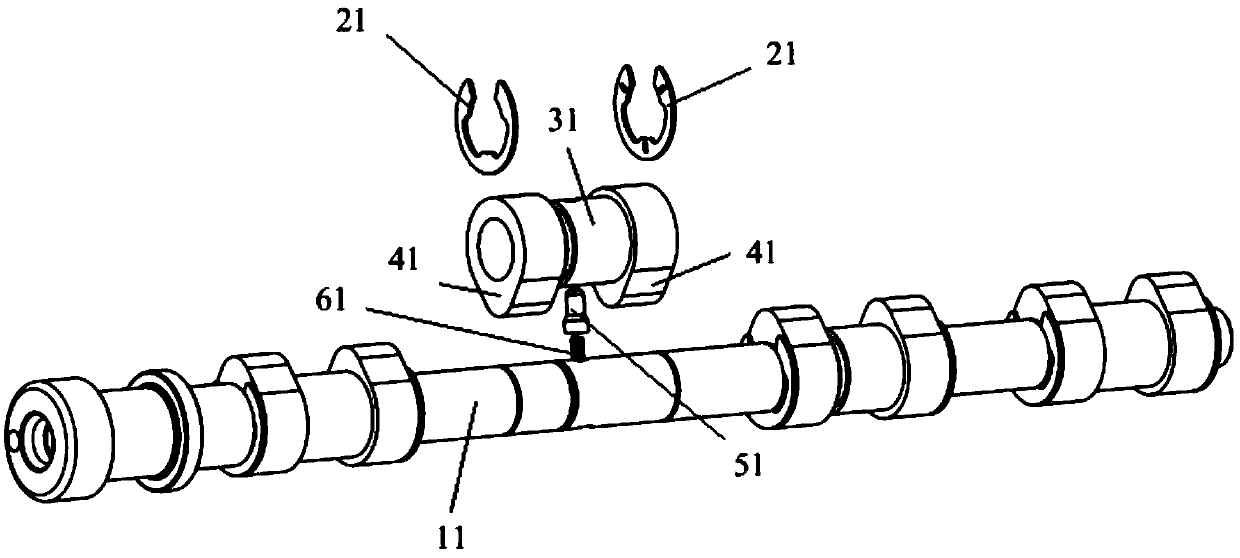

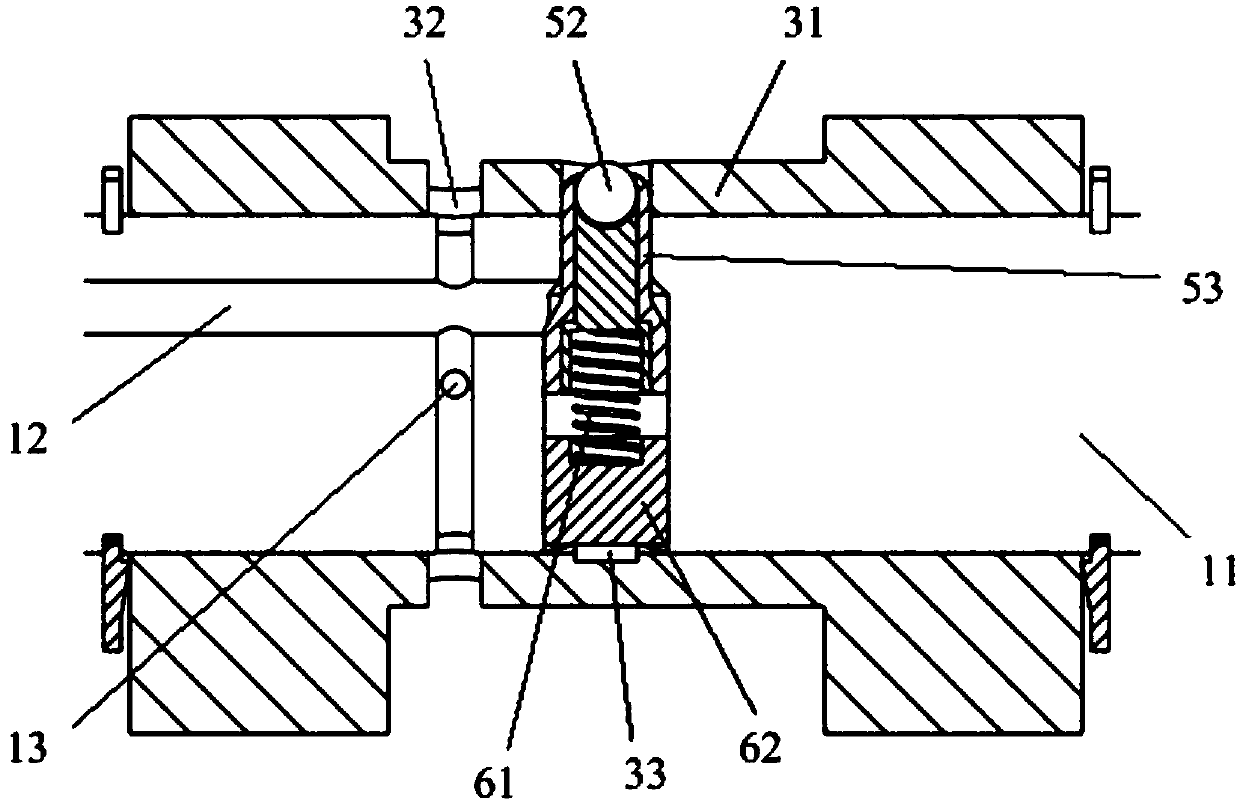

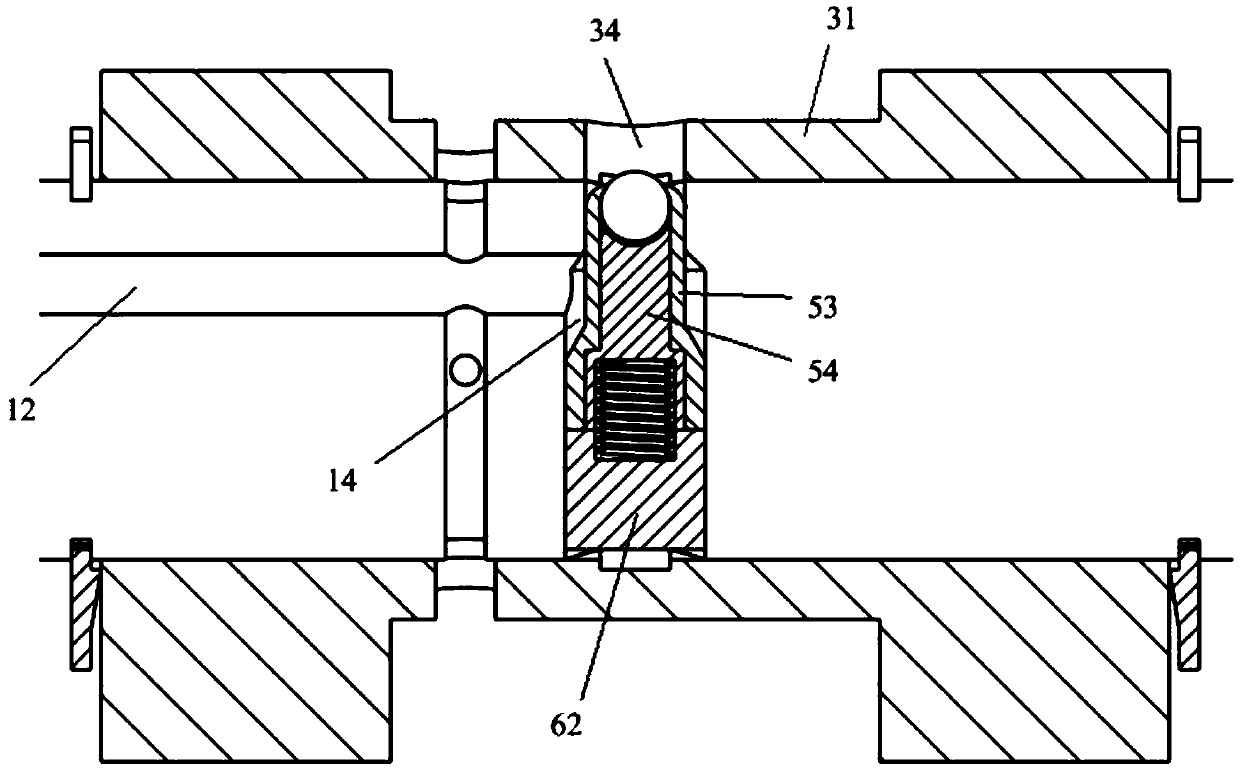

[0037] like Figure 1 to Figure 10 As shown, the embodiment of the present invention provides an engine cylinder deactivation mechanism, which includes a camshaft 11, a sleeve 31, a cam 41 and a thrust plate 21, the sleeve 31 is sleeved on the camshaft 11, the The inner wall of the sleeve 31 is rotatably matched with the outer surface of the camshaft 11, and the cam 41 is fixedly arranged on the sleeve 31; the two thrust plates 21 are oppositely arranged on the camshaft 11, and respectively It is in contact with both ends of the sleeve 31; a locking hole 34 is provided on the outer surface of the sleeve, and a receiving hole corresponding to the locking hole 34 is provided on the camshaft. A locking mechanism is provided in the accommodating hole, and the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com