Swept back arc type pneumatic atomizing evaporative stabilizer

A pneumatic atomization and evaporation technology, applied in ramjet engines, combustion methods, lighting and heating equipment, etc., can solve problems such as inability to meet high-efficiency flame stabilization requirements, low work reliability, and complex welding processes, and achieve airflow and fuel switching effect, high reliability, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

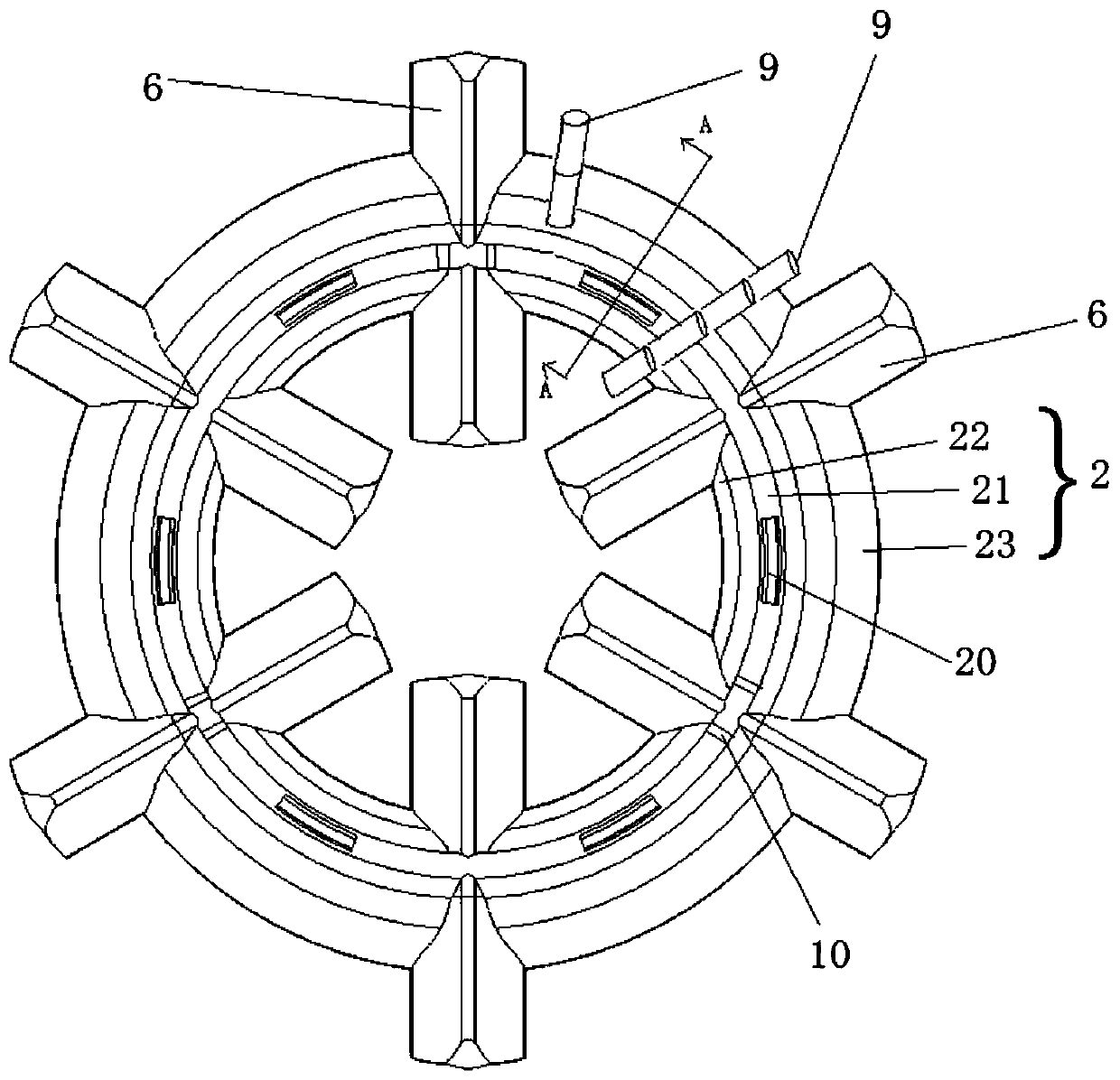

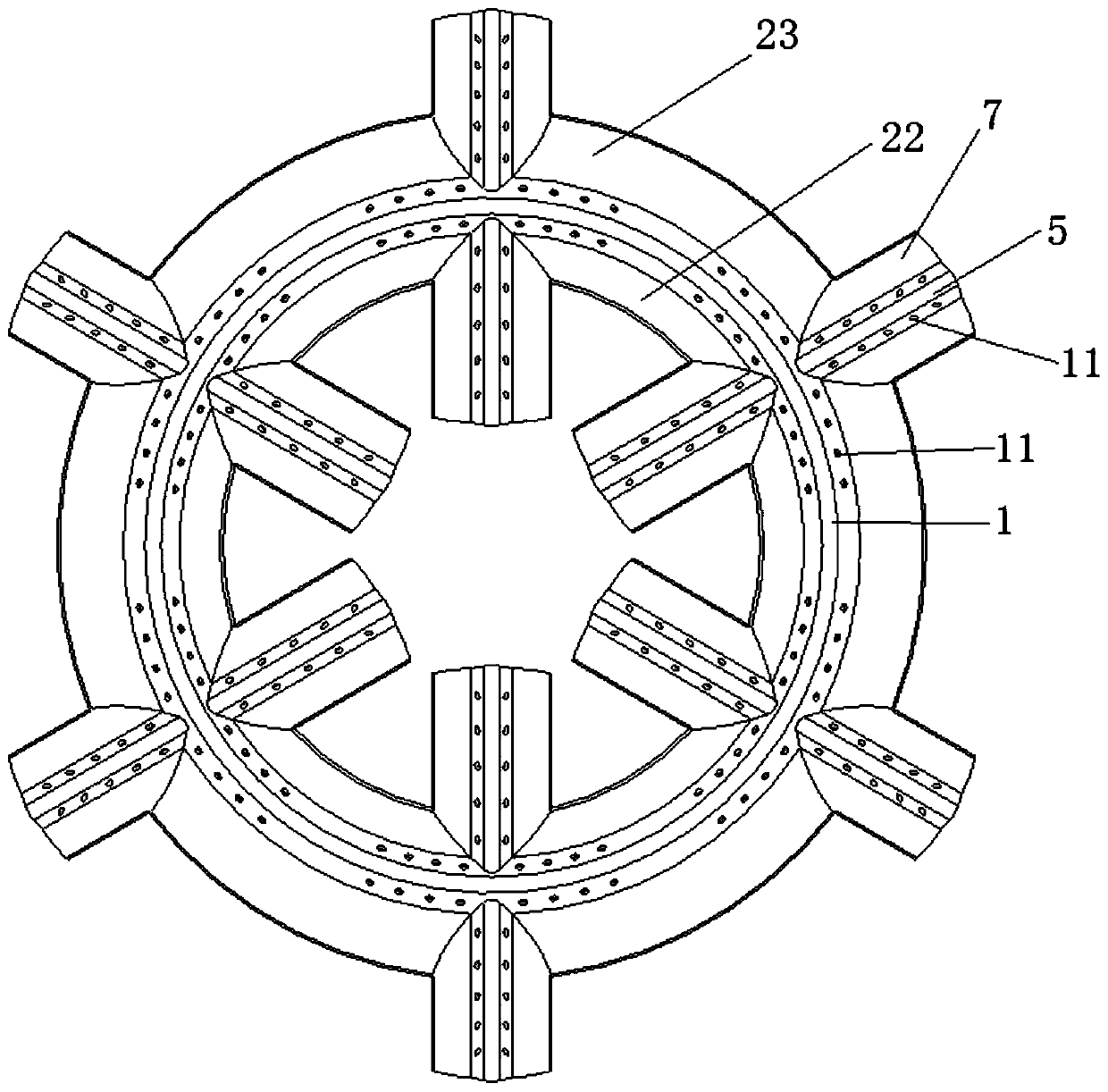

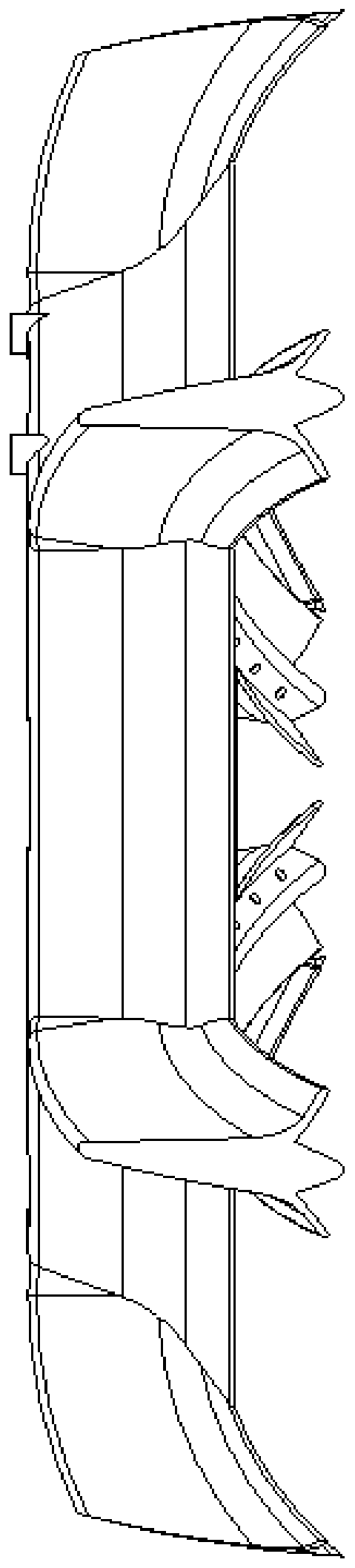

[0036] Such as Figure 1 to Figure 3 As shown, a back-swept circular arc type pneumatic atomization evaporation stabilizer includes a concentrically arranged annular evaporator tube 1 and an annular turbulent body 2, and an annular turbulent body 2 is provided on the incoming flow direction of the annular evaporator tube 1, At least one row of evaporation hole groups is provided on the rear wall of the circumferential evaporation tube 1, each row of evaporation hole groups includes a plurality of circumferentially distributed evaporation holes 11, and the annular turbulence body 2 includes a front ring body 21, an inner ring surface 22 and the outer annular surface 23, the front annular body 21, the inner annular surface 22 and the outer annular surface 23 are integral parts; The gas port 20 forms an overflow channel (the channel formed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com