Ramjet Combustion Chamber Stabilizer and Flame Stabilization Method

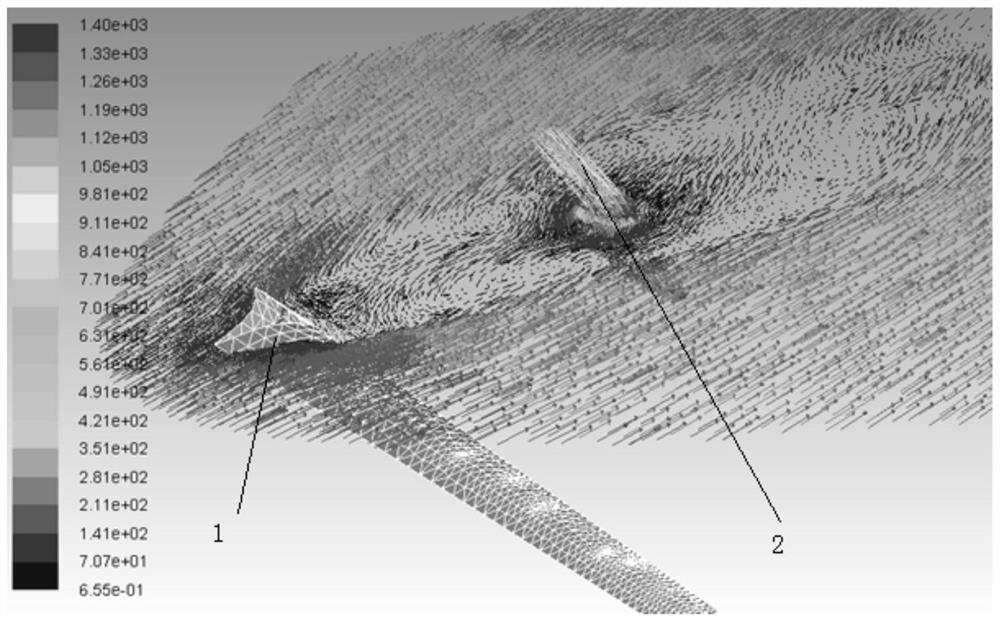

A technology of ramjet engine and combustion chamber, which is applied in the direction of combustion method, combustion chamber, continuous combustion chamber, etc., can solve the problems of large aerodynamic loss of mechanical flame stabilizer, inability to meet the requirements of high efficiency and stable flame, and low working reliability, so as to achieve increased The effect of jet penetration depth and mixing effect, improving atomization effect and improving flame stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

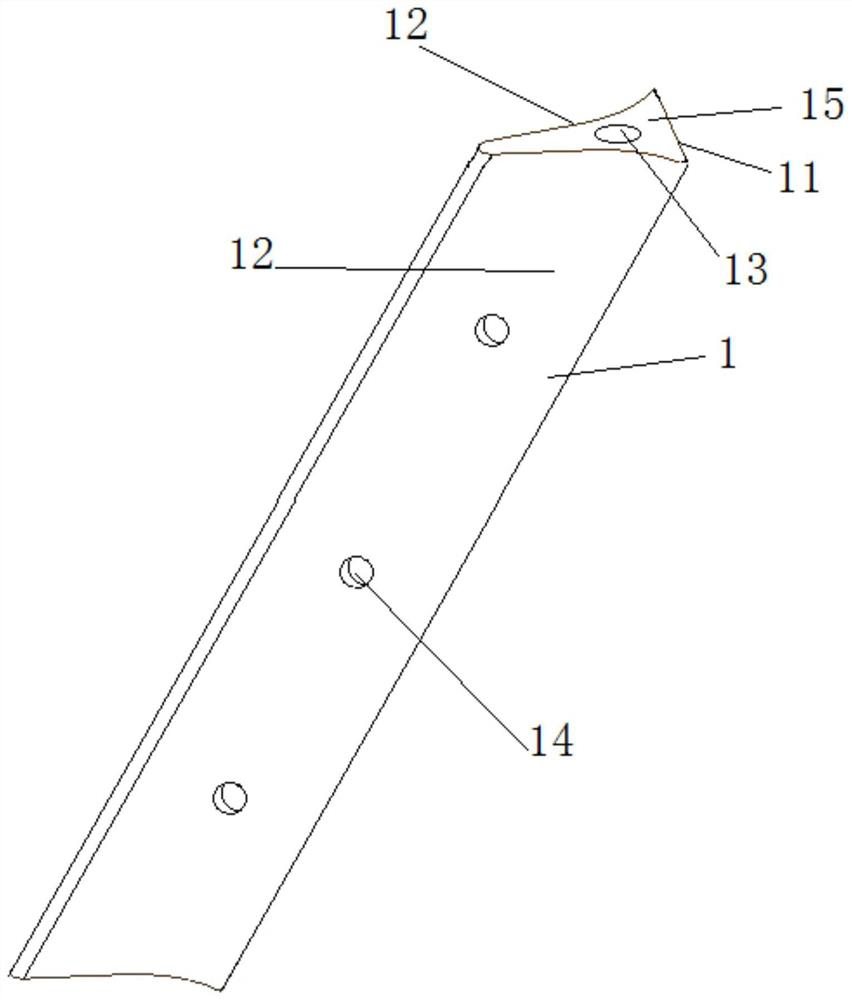

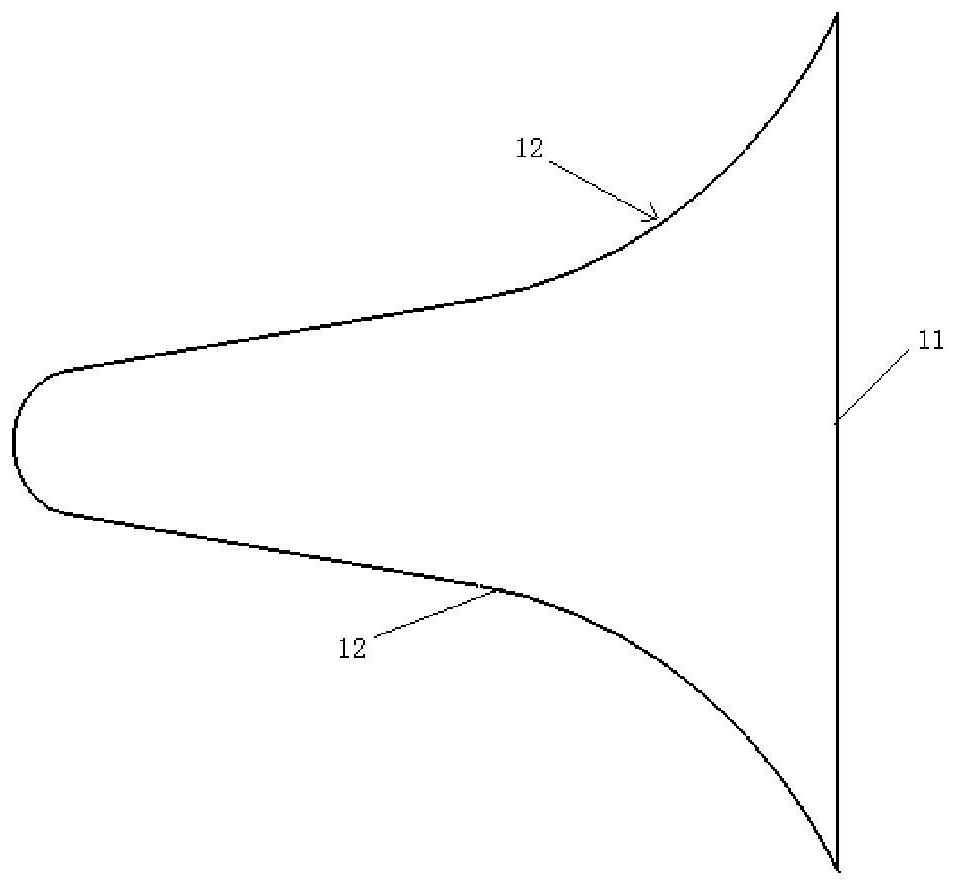

[0039] A ramjet combustion chamber stabilizer is characterized in that it includes a swept back arc-shaped support plate 1, and the swept-back arc-shaped support plate 1 includes a bottom surface 11, two end surfaces 15 and two side profiles 12; The cross-section of the swept-back arc support plate 1 is triangular; the front parts of the two side profiles 12 are connected, and the two side profiles 12 are respectively concaved to form arc side profiles. The existence of the arc at the rear of the surface 12 has a large enough deflection angle for the incoming flow, and can generate a large recirculation zone with a small blocking ratio, which is conducive to uniform mixing of fuel, stable flame, and high-efficiency combustion. The intersection of the two side profiles 12 is a smooth transition.

[0040] A blind hole 13 extending to the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com