Inverted roller screw reduction gear

A technology of reducer and nut, which is applied in the direction of gear transmission, belt/chain/gear, program control manipulator, etc., which can solve the problems of occupation and inability to be used as output components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

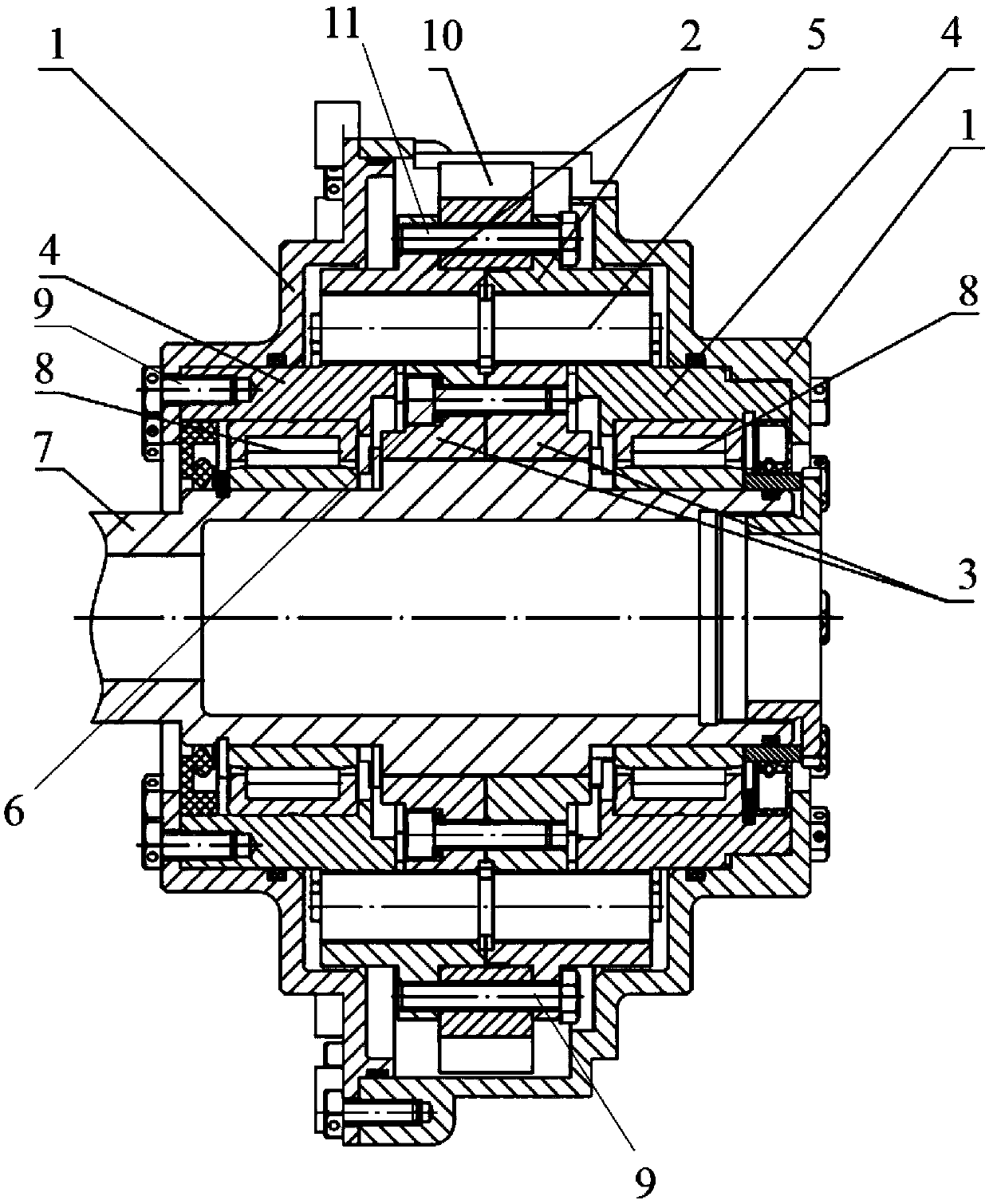

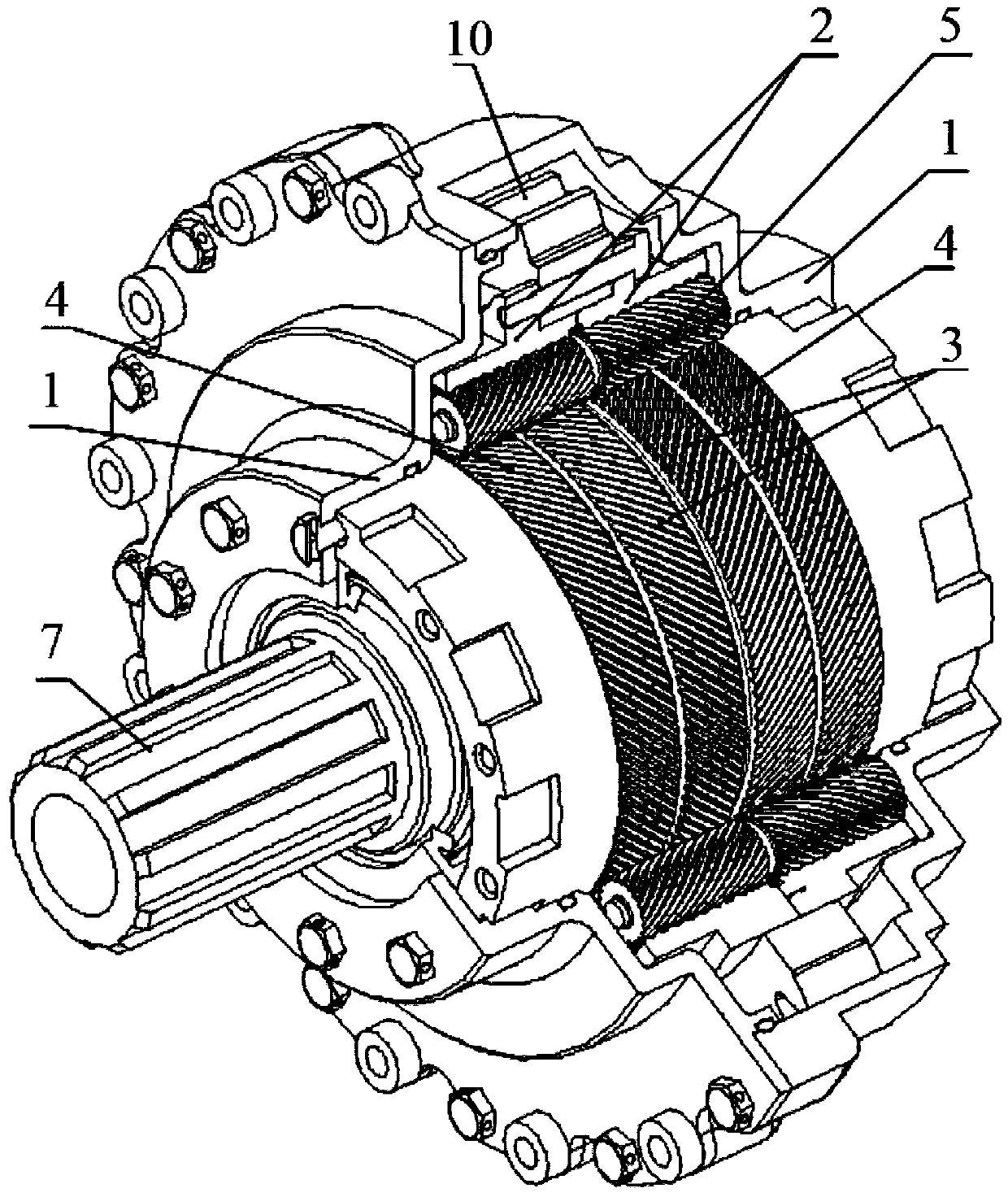

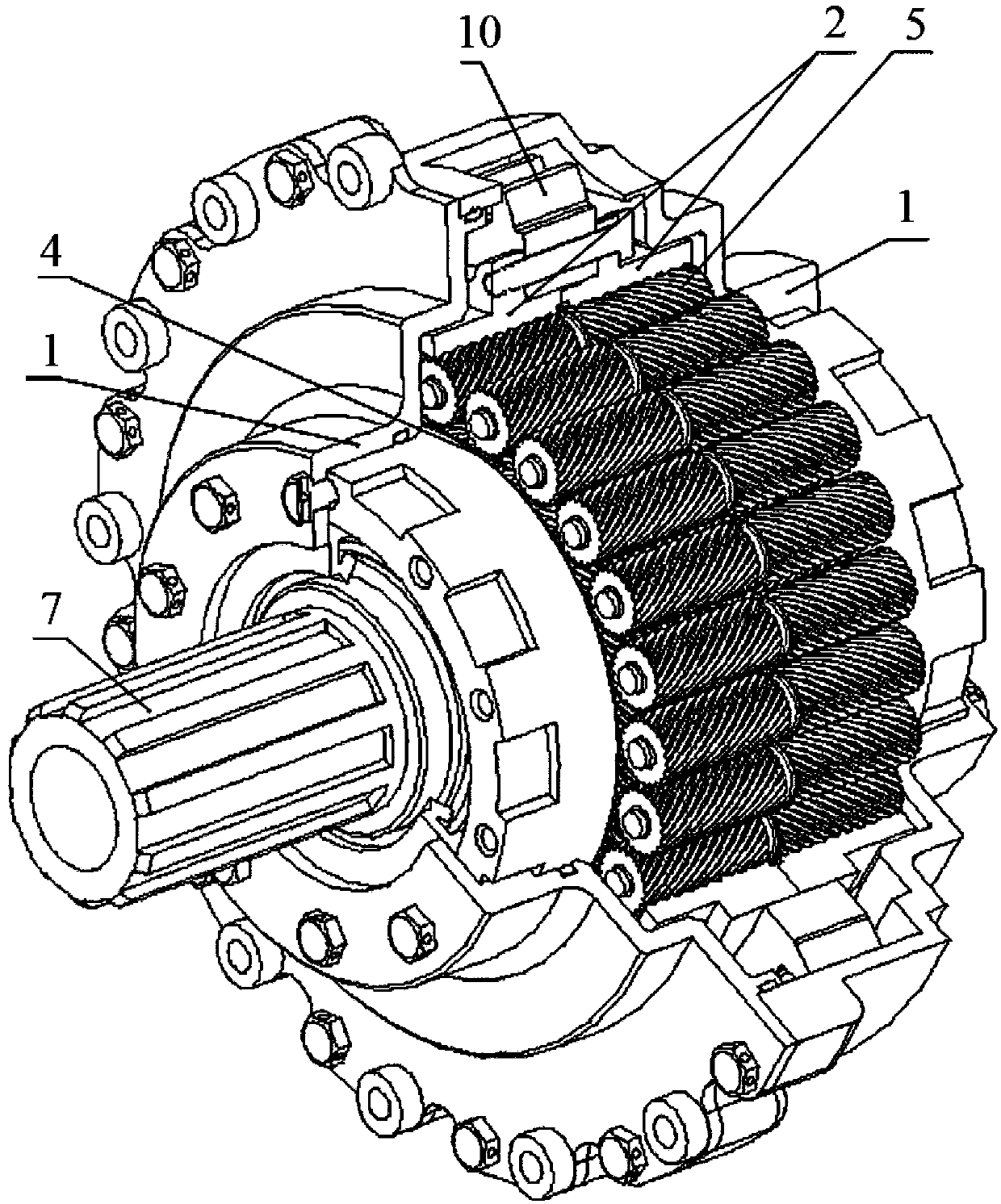

[0032] exist figure 1 In one embodiment shown, a roller reducer comprises a main body 1 receiving a reducer input member, an output member, a support member and a roller 5 . The input member includes two input member nuts 2 . The output member includes two output member nuts 3 . The support member comprises two support member nuts 4 .

[0033] Although the illustrated roller reducer includes two input member nuts 2, two output member nuts 3 and two support member nuts 4, the invention is not limited to the illustrated embodiment and the roller reducer may include more Various types of nuts.

[0034] The two output member nuts 3 cannot be displaced axially, since they are fixedly mounted relative to each other by means of a fixing member, for example by a threaded rod 6 inserted into a dedicated groove in the nut 3 . In order to prevent angular displacement of the nuts 3 relative to each other, the nuts may be connected by a spline joint (not shown).

[0035] Alternatively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap