Axial and lateral bidirectional simple centering equipment of gas turbine

A centering device and gas turbine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, low adjustment accuracy, etc., achieve simple installation and operation methods, strong versatility, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

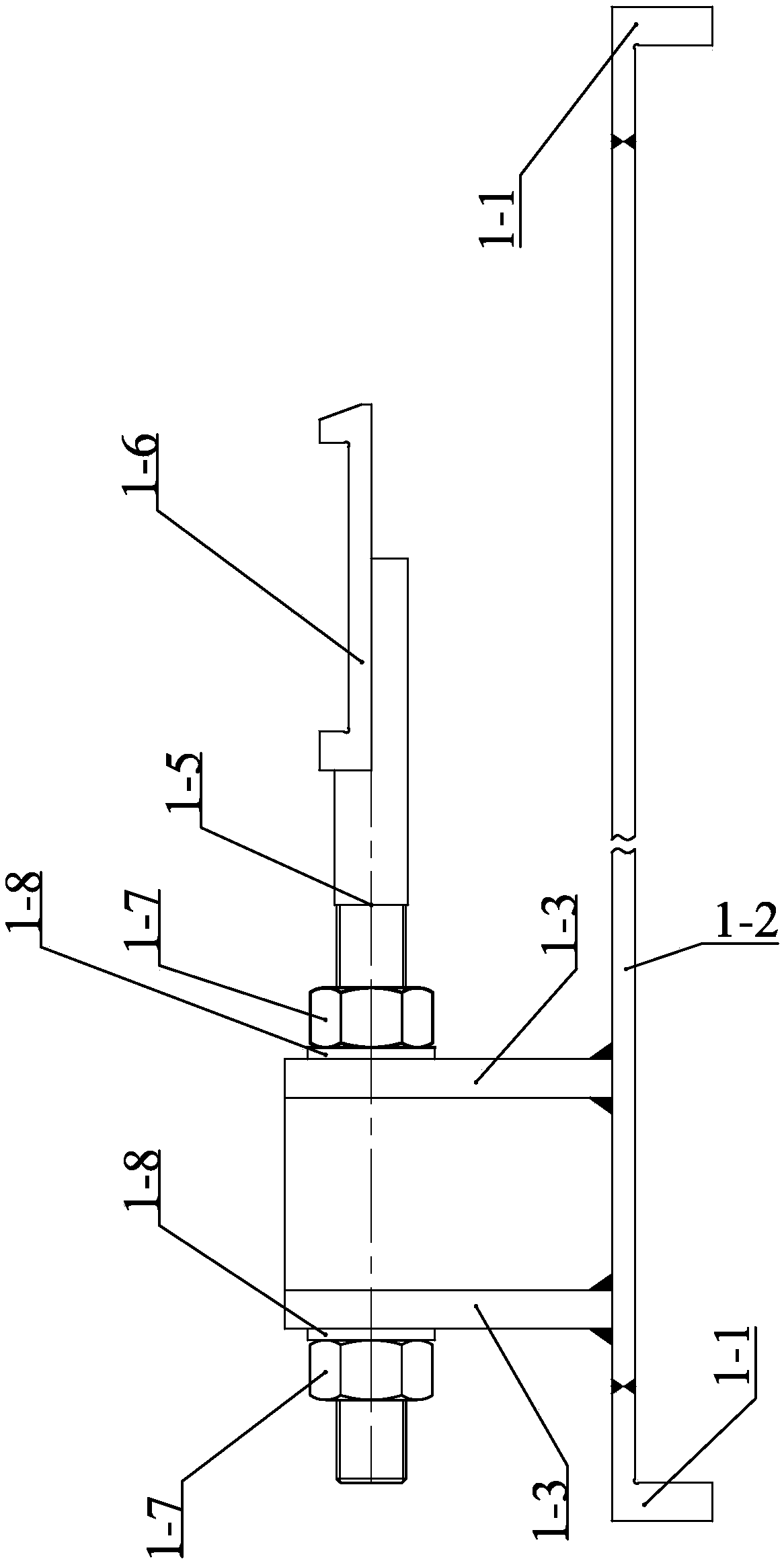

[0016] Embodiment 1: According to Figures 1 to 5 Illustrating this embodiment, a simple axial and lateral bidirectional centering device for a gas turbine includes an axial centering device 1 and a lateral centering device 2; the axial centering device 1 includes an end plate 1-1, a No. 1 base plate 1-2, support plate 1-3, tie rod 1-5, connecting plate 1-6 and nut 1-7; end plate 1-1 is fixedly connected to both ends of No. 1 base plate 1-2; support plate 1-3 The number is two, and they are all "U"-shaped plates. The support plates 1-3 are vertically fixed and connected to the No. 1 base plate 1-2 with the open end upward. The two support plates 1-3 are parallel to each other along the No. 1 base plate 1- 2. Set in the length direction; one end of the tie rod 1-5 is provided with a thread, the threaded end of the tie rod 1-5 passes through the "U"-shaped grooves of the two support plates 1-3, and is fixed with a nut on the outside of the support plate 1-3, and the pull rod Th...

specific Embodiment approach 2

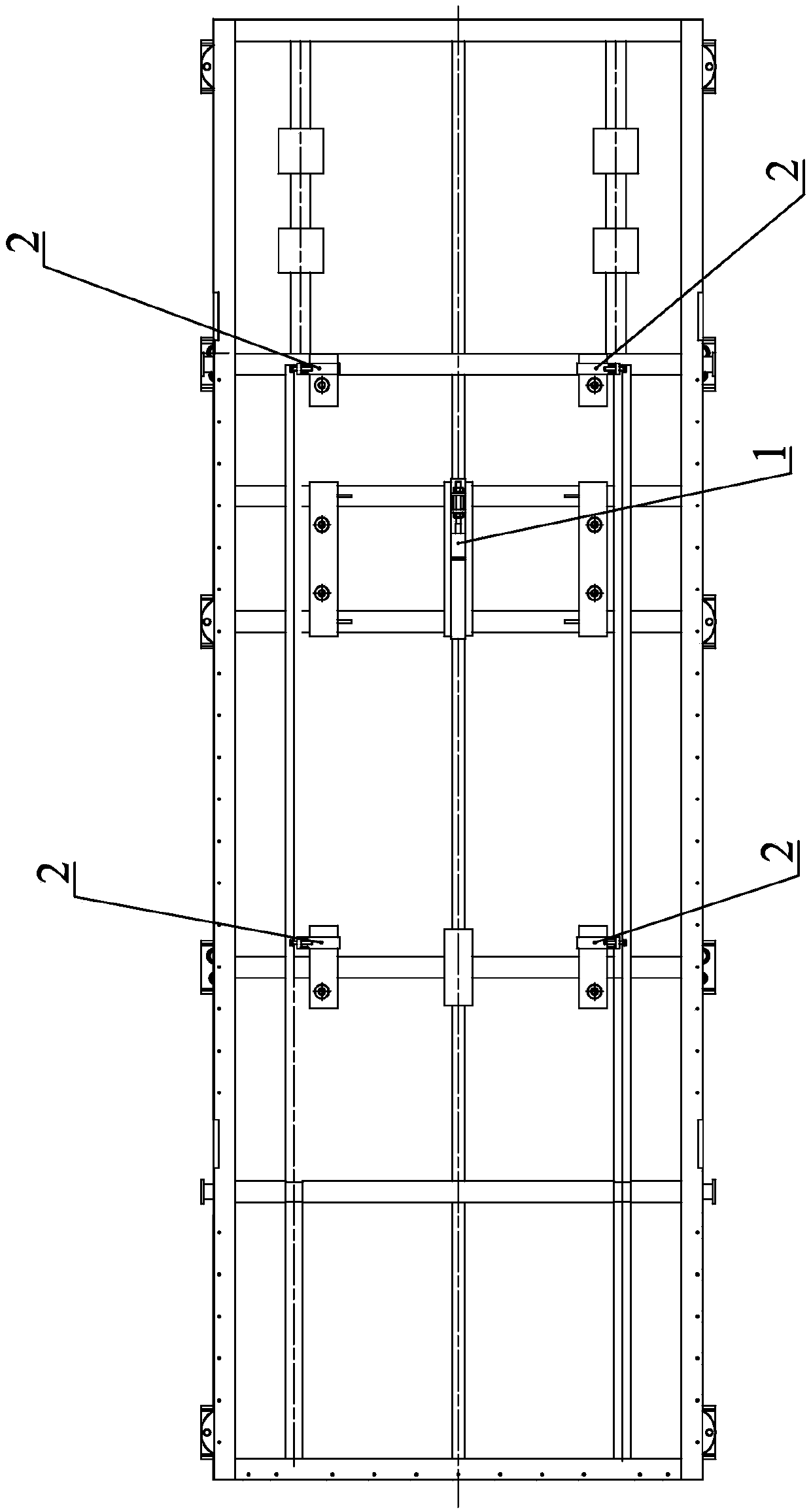

[0017] Specific implementation two: according to figure 1 Illustrating this embodiment, the simple axial and lateral two-way centering device for a gas turbine further includes a large chassis 3, and the axial centering device 1 and the lateral centering device 2 are arranged on the large chassis 3, and the four Two lateral centering devices 2 are respectively arranged at the four corners of the large chassis 3, and one axial centering device 1 is disposed in the middle of the large chassis. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

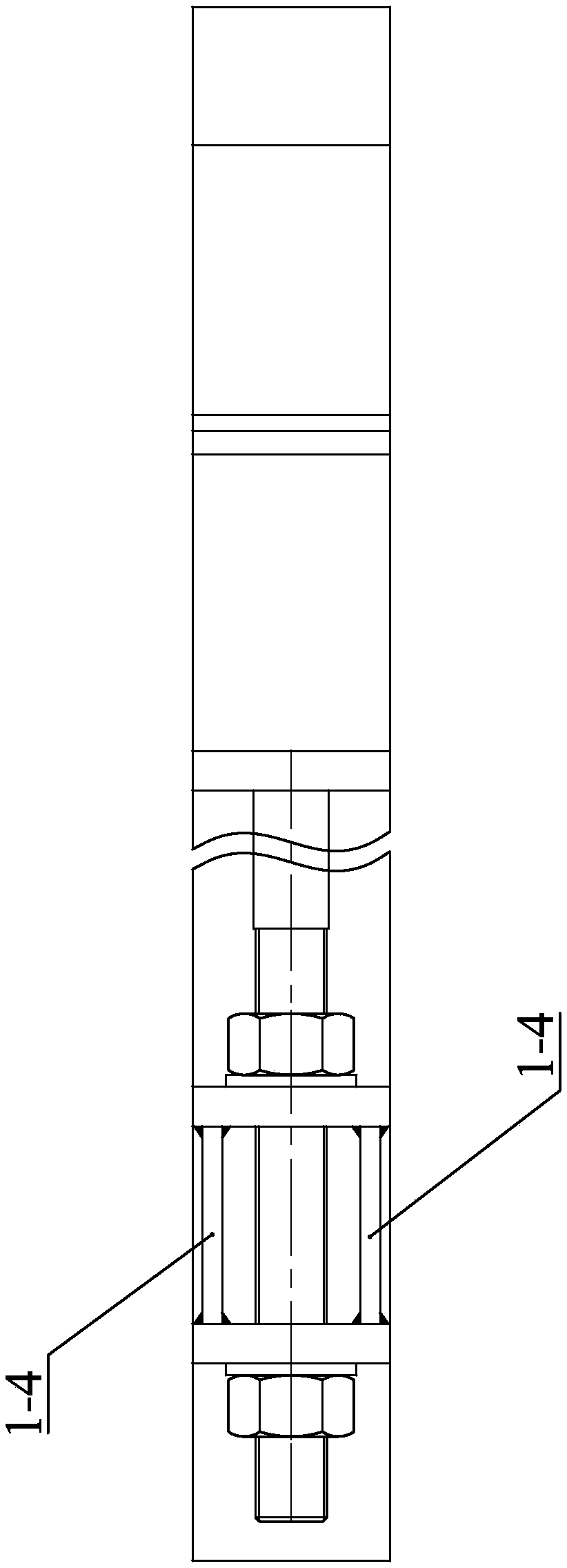

[0018] Specific implementation three: according to image 3 Illustrating this embodiment, the axial centering device 1 further includes an intermediate plate 1-4, the intermediate plate 1-4 is a rectangular plate, and is vertically and fixedly connected between the two support plates 1-3. The addition of the intermediate plate makes the axial centering device 1 more stable during operation. Other compositions and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com