Open tunnel ship type reversing performance enhancement method and device

A tunnel and ship type technology, applied in the direction of ship hull, hull parts, ship construction, etc., can solve the problems that the tunnel cannot be filled with water, low propulsion efficiency, loss of thrust, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

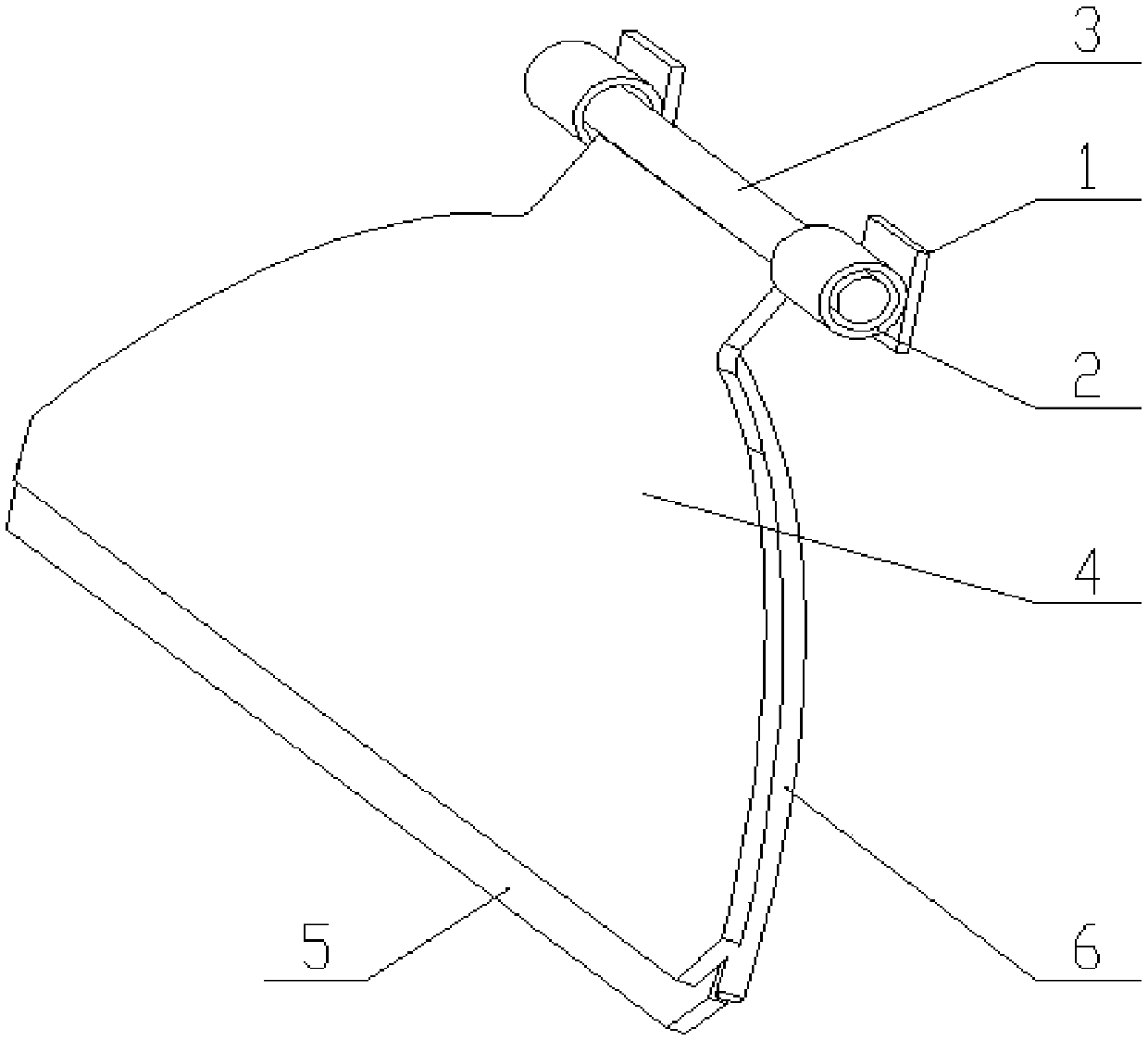

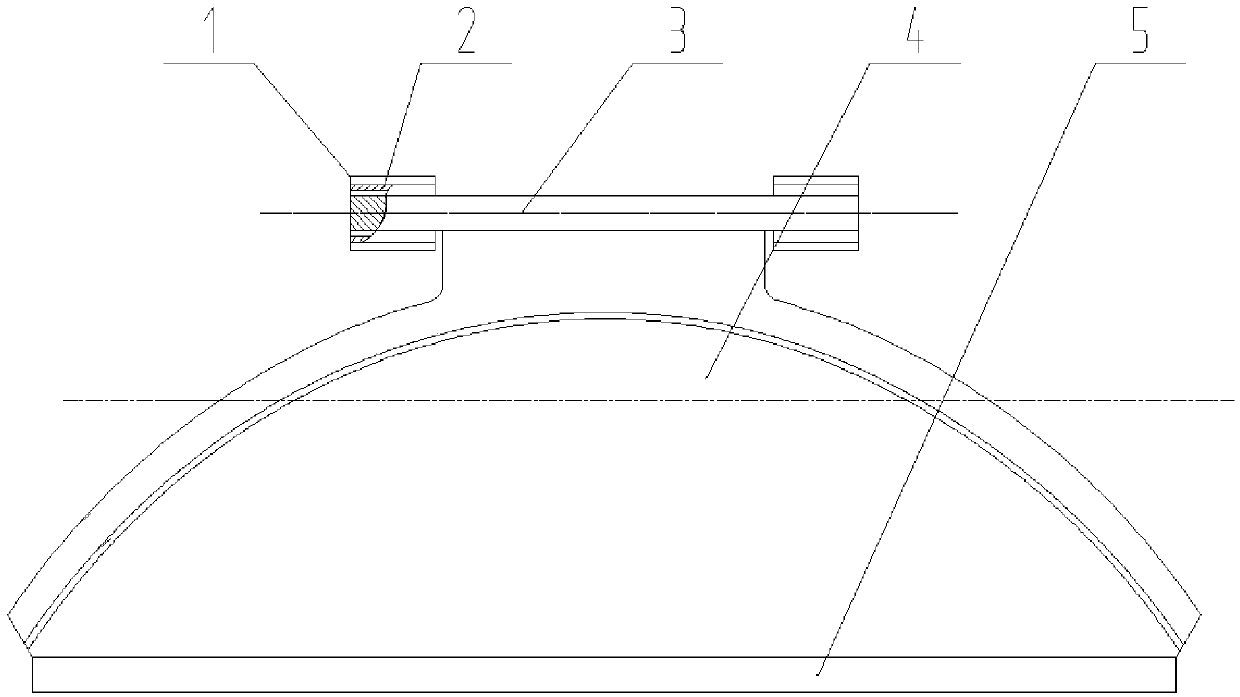

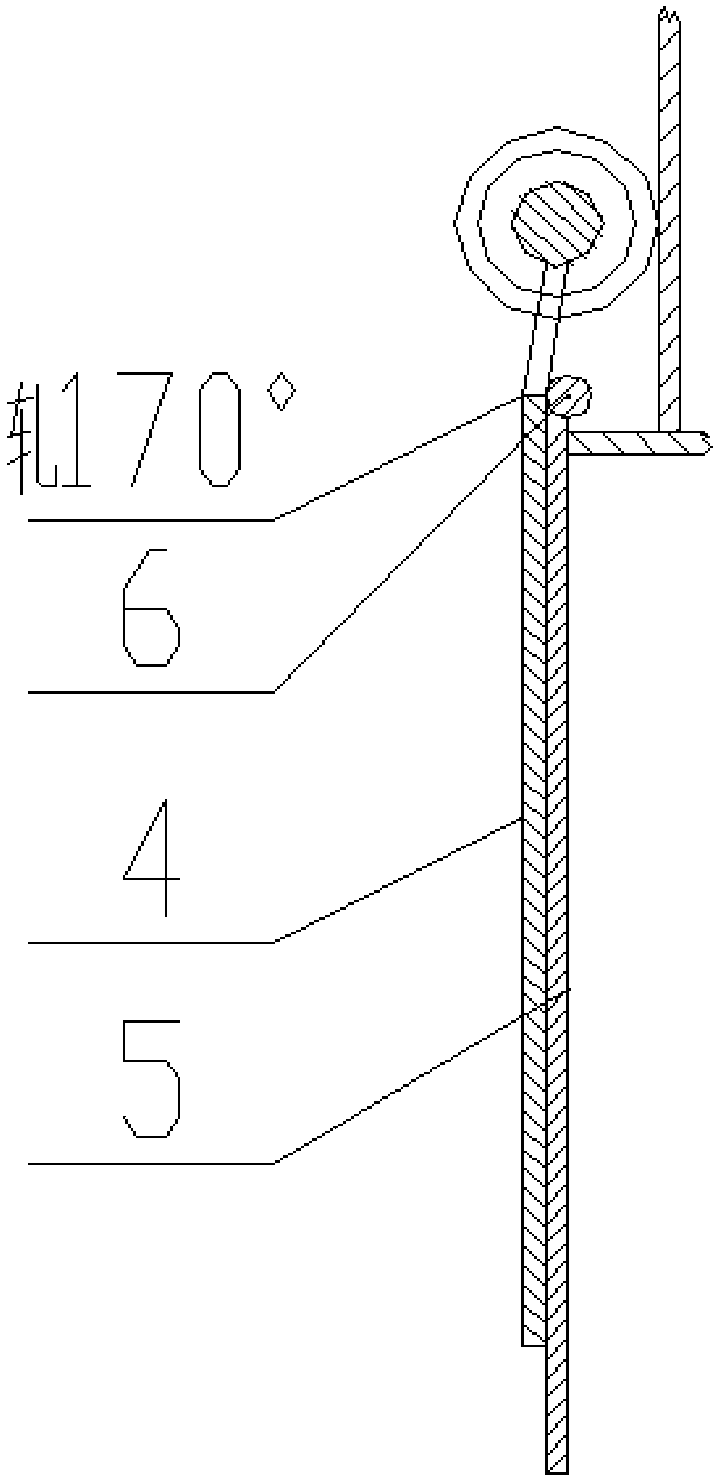

[0024] see Figure 1-5 , a ship-type reversing performance enhancement method for an open tunnel to improve the reversing propulsion efficiency of an open tunnel. A closed space is formed at the tail, so that the air above the tunnel is evacuated to form a vacuum, and then the water is sucked in to fill it up, so that the propeller is completely submerged in the water when the car is reversing; but this device must be opened when the car is moving forward, so as not to affect the drainage of the tunnel backward. Based on the above needs, a reversible baffle is installed behind the tail seal. When driving forward, use the backward water thrust to push it away to ensure the shape of an open tunnel; when reversing, rely on the resistance of the water to press the baffle against the tail seal. above, forming a closed space similar to a closed tunnel. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com