Optical microhand based on three-core optical fibre

A three-core optical fiber, single-core optical fiber technology, applied in the field of optical micro-hand, can solve the problems of complex three-dimensional optical waveguide preparation technology, large optical power loss, difficult interconnection, etc. Great capture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in more detail below in conjunction with accompanying drawing example:

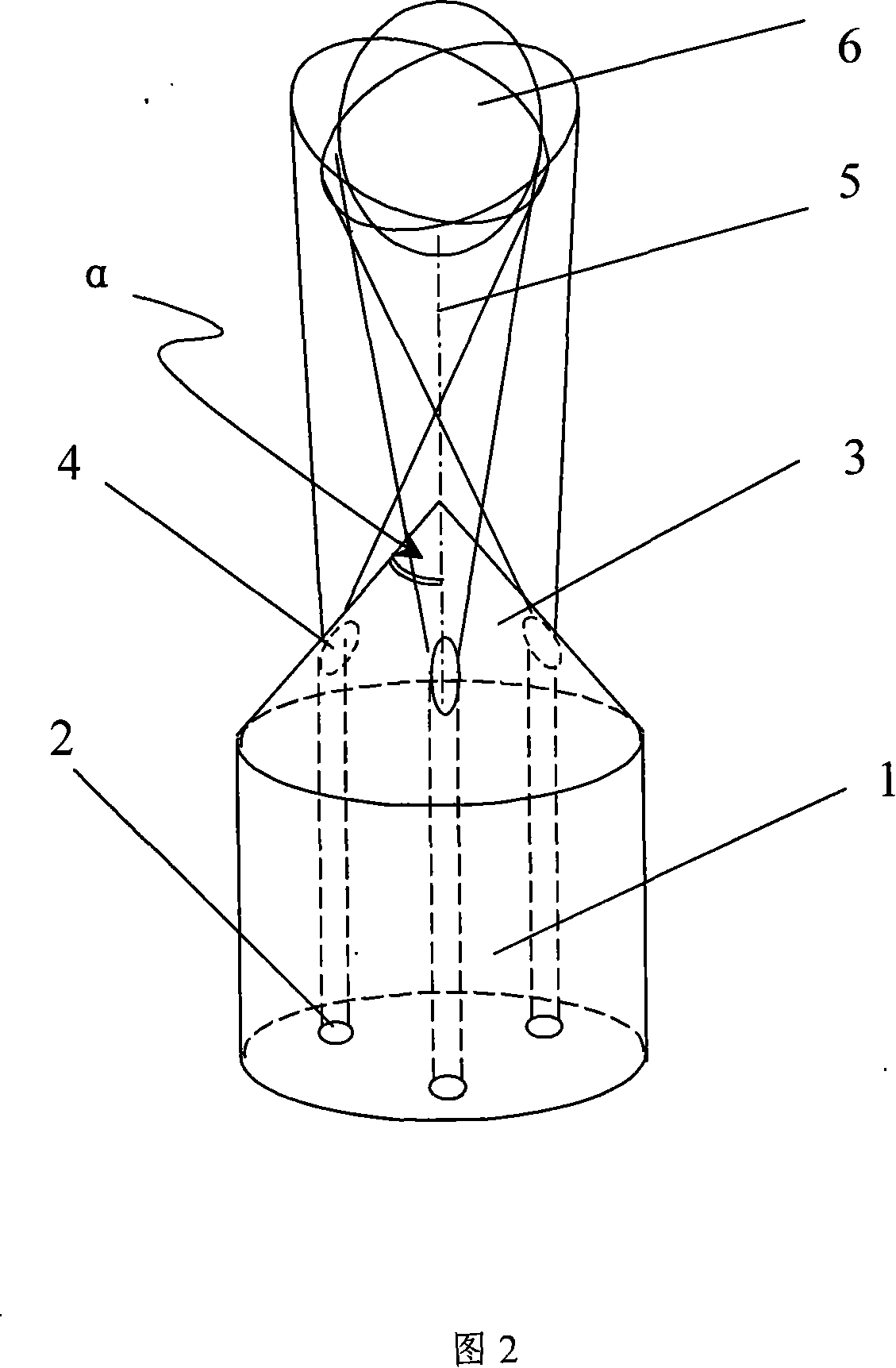

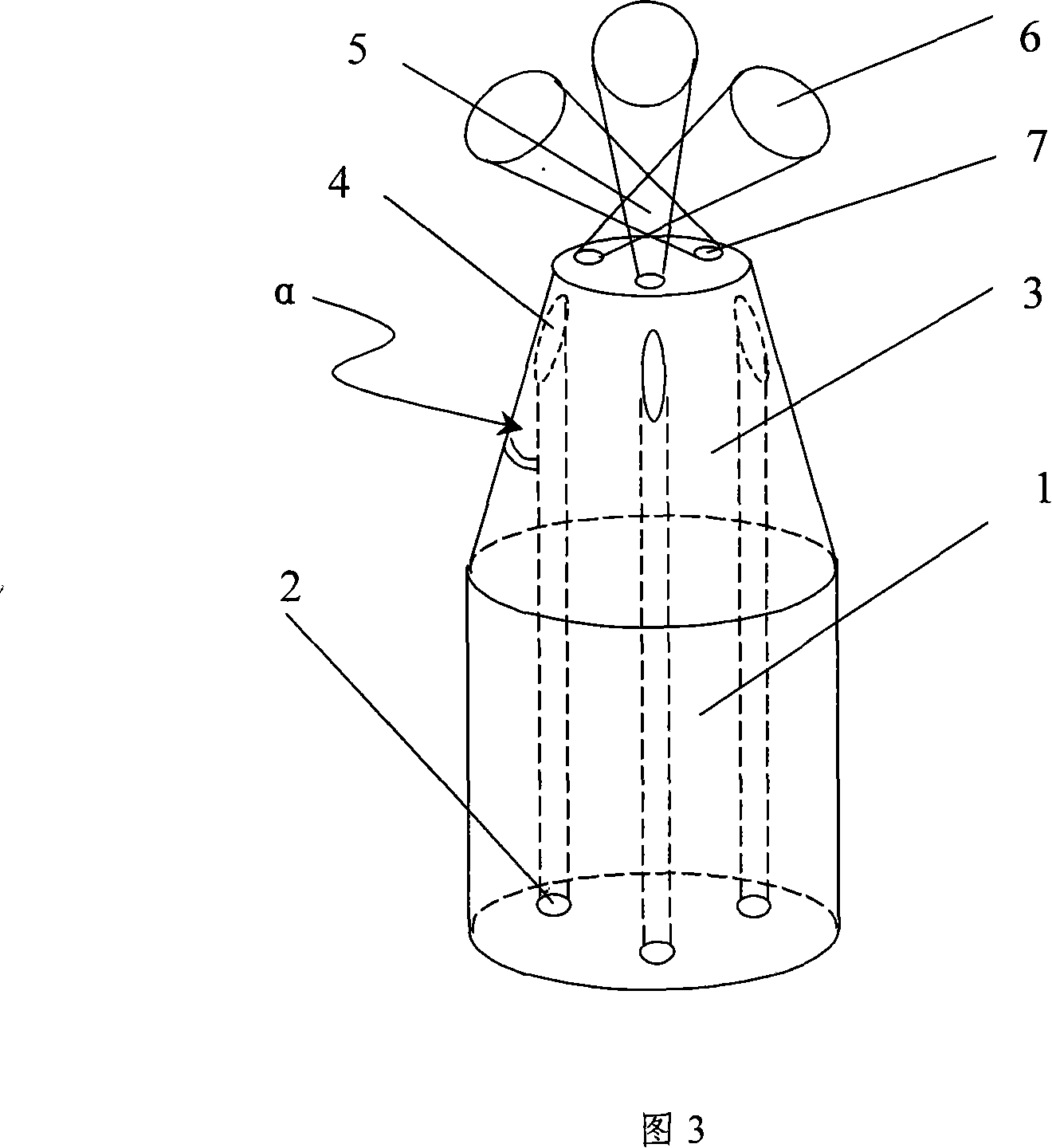

[0032] In conjunction with Fig. 2, the optical micro-hand of the first embodiment of the present invention includes an optical fiber, and the optical fiber includes a three-core optical fiber and a single-core optical fiber coupled and connected to the tail end of the three-core optical fiber, and the front end of the three-core optical fiber passes through the grinding of the optical fiber end It is made into a cone by the method of sintering at the tip after processing or heating to melt the taper. Among them: 1 is an optical fiber with a three-core structure; 2 is an optical fiber core in an equilateral triangle distribution state; 3 is an optical fiber end ground into a cone; 4 is an optical fiber core in an equilateral triangle distribution state exposed on the surface of the cone; 5 is the intersection area of the three exiting light fields; 6 is the far f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com