Vehicle component buffering mechanism

A technology of auto parts and cache mechanism, which is applied in the field of auto parts, can solve the problems of using a lot of space, a lot of manpower and material resources, and damage to the structure of parts, so as to save time and space and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

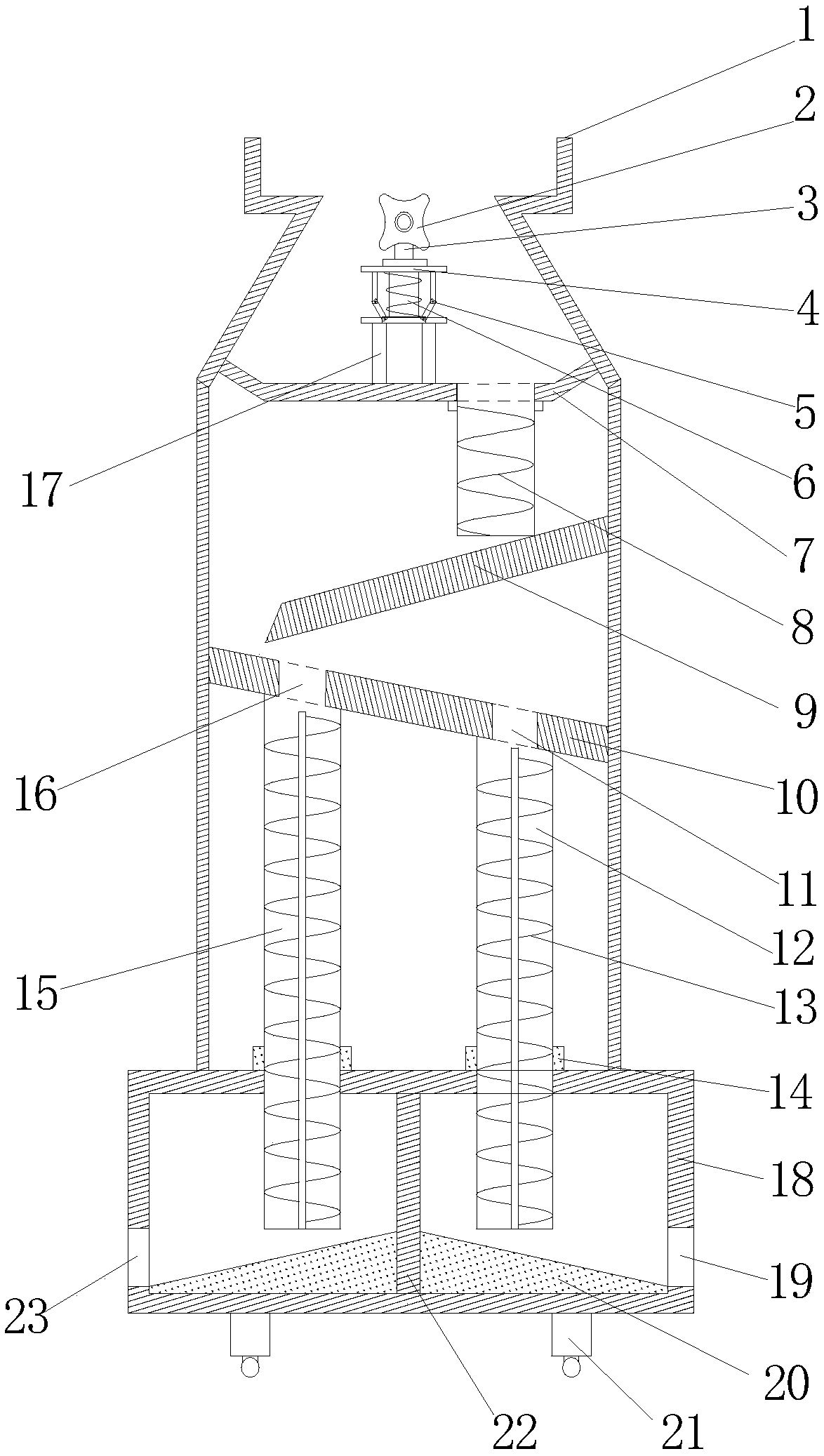

[0017] figure 1 It is a cross-sectional view of the present invention, as shown in the figure, a buffer mechanism for auto parts, including a buffer chamber 1 and a frame 18 arranged at the bottom of the buffer chamber 1 for installing the buffer chamber 1. The first buffer assembly, the second buffer assembly, and the third buffer assembly for buffering parts are arranged in sequence in the direction; the first buffer assembly includes a star-shaped rotating disk 2, and the star-shaped rotating disk 2 is arranged in a star-shaped The buffer structure below the rotating disk 2, the circular tray 7 that is arranged below the buffer structure and supports the buffer structure; the star-shaped rotating disk 7 is recessed inward to form an arc segment for buffering parts, and the buffer structure Including the buffer upper plate 4, the buffer lower plate 24, the spring 6 and the connecting rod 5 arranged between the buffer upper plate 4 and the buffer lower plate 24, the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com