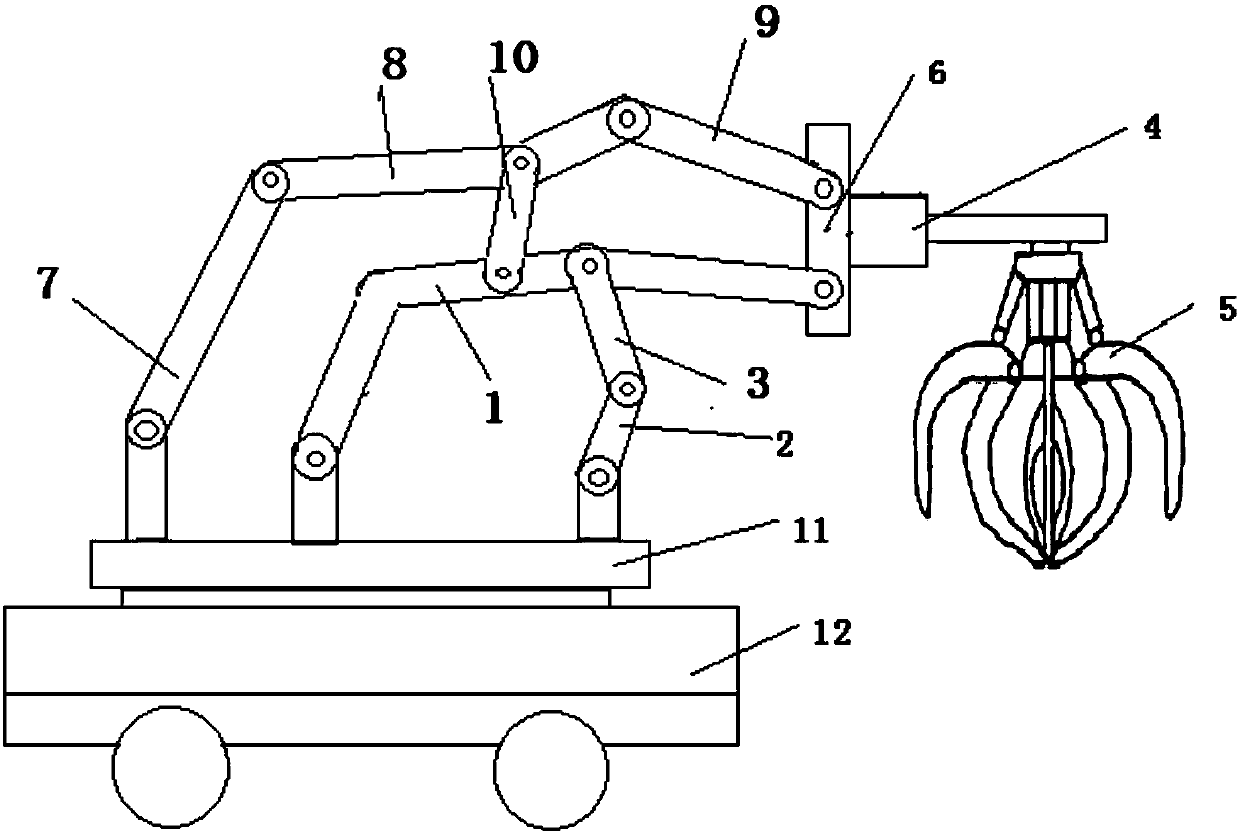

Method for grabbing and loading waste with multi-freedom-degree linkage mechanism

A linkage mechanism and degree of freedom technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as high precision requirements, complex structures, and reduced dynamic performance, and achieve the effect of overcoming high precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0009] Working example: a method of grasping and loading waste using a multi-degree-of-freedom linkage mechanism. During work, the lifting mechanism composed of the boom 1, the boom driving rod 2, and the boom connecting rod 3 drives the wrist and claw of the industrial waste grabbing machine. Lifting up and down, the pitching mechanism that forearm driving rod 7, forearm 8, forearm connecting rod 9 and big and small arm connecting rod 10 form drives industrial waste grasping machine wrist and pawl pitching motion simultaneously. A working cycle process of grabbing industrial waste is: after the gripper grabs industrial waste, the rotary platform rotates to rotate the gripper for grabbing industrial waste to the set position, and the motor drives the arm drive rod 2 to realize the lifting of the wrist link 6. After reaching the designated industrial waste grabbing position, the motor drives the forearm drive rod 7 to realize the wrist connecting rod 6 to bend down, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com