Faceplate dam crack repairing structure

A technology for repairing structures and face dams, applied in water conservancy projects, sea area projects, construction, etc., can solve problems such as waste of hydraulic resources, uneconomical, difficult to meet construction appearance requirements, etc., to achieve convenient production, easy purchase, significant economic benefits and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

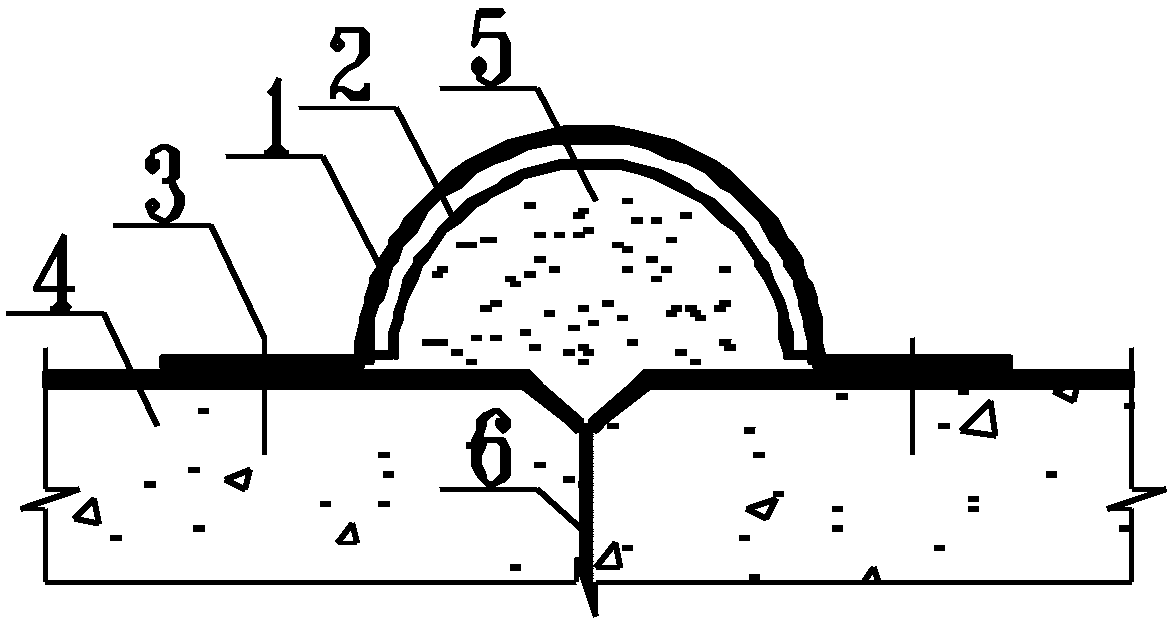

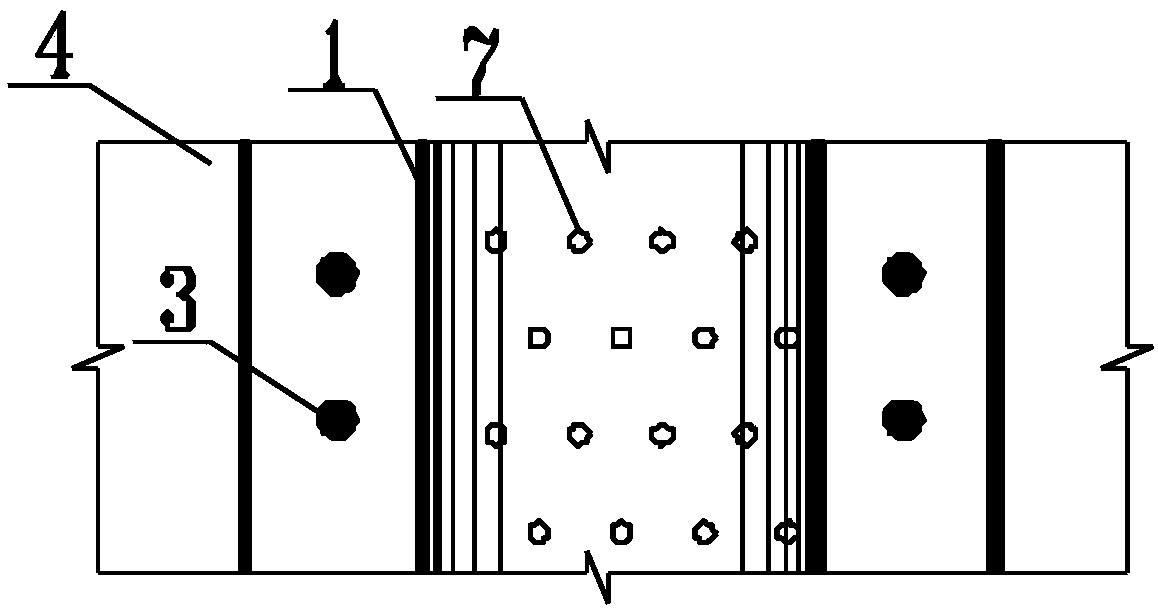

[0019] Such as figure 1 , figure 2 A panel dam crack repair structure shown includes a protective tube 1 and a non-woven geotextile 2; the edge of the protective tube 1 is flat and has an arc-shaped protrusion in the middle, and the non-woven geotextile 2 is fixed in the middle of the protective tube 1 On the inner wall of the arc-shaped protrusion, there is an opening 7 on the arc-shaped protrusion of the protection tube 1, the arc-shaped protrusion of the protection tube 1 is facing the expansion joint 6 of the concrete panel 4, and the arc-shaped protrusion of the protection tube 1 and the concrete panel 4 There is a filler in the space formed.

[0020] The arc-shaped protrusion in the middle of the protection tube 1 is in the shape of a semicircle or a hemisphere.

[0021] The filler is fly ash5.

[0022] The openings 7 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com