Automatic dust removal electric power distribution cabinet

A technology for automatic dust removal and power distribution cabinets, which is applied in substation/power distribution device shells, electrical components, substation/switch layout details, etc., and can solve potential safety hazards, dust entering power distribution cabinets, and damage to equipment in power distribution cabinets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

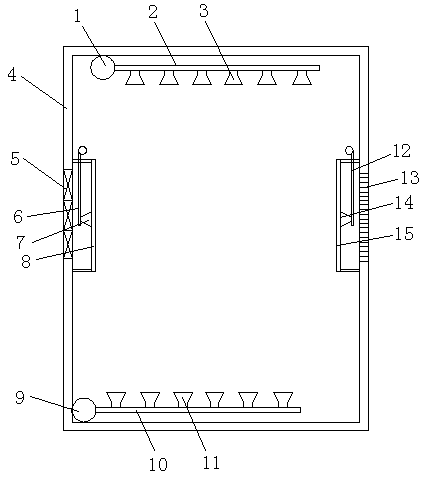

[0030] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

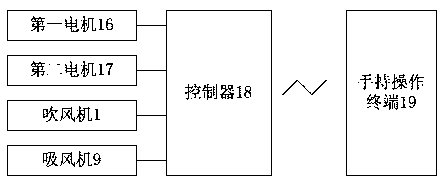

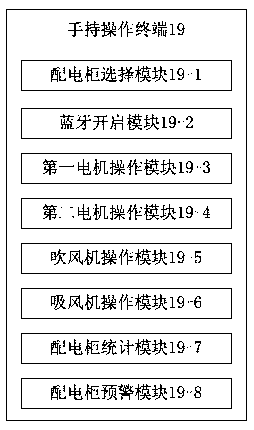

[0031] Such as Figure 1-3 As shown, the automatic dust removal power distribution cabinet provided in this embodiment includes a cabinet body 4 on which a ventilation window 13 and an exhaust fan 5 are arranged. In order to prevent too much dust from entering the cabinet body 4, the first dust filter net 15 is generally arranged at the ventilation window 13 in the cabinet body 4, and the second dust filter net 8 is set at the exhaust fan 5 place in the cabinet body 4.

[0032] After a long time, there will be more dust on the first dust filter net 15 and the second dust filter net 8. In this embodiment, a first roller shutter plate 12 driven by a first motor 16 is arranged between the ventilation window 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com