Hearing aids based on 4D printed shape memory materials

A technology of memory materials and hearing aids, which is applied to hearing aids, hearing aid shells, electrical components, etc., can solve the problems of easy interference between the vibrator and mastoid connection, weak connection relationship, and difficulty in fitting hearing aids and skulls. Good surgical prognosis, reduced trauma, and improved energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

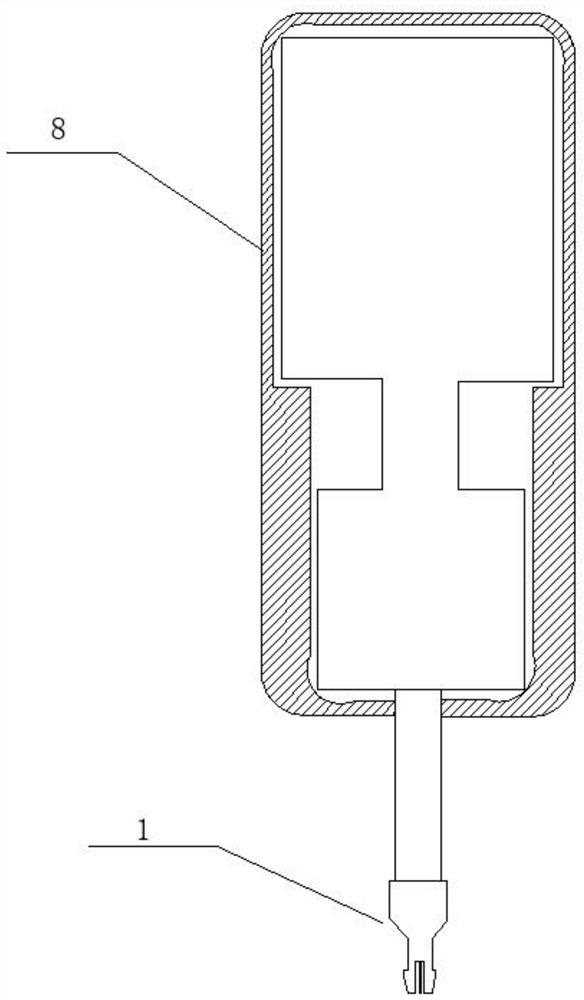

[0033] like figure 1 As shown, a hearing aid based on 4D printing shape memory material includes a hearing aid body, and the outer part of the hearing aid body is wrapped with a protective cover 8, and the protective cover 8 is made of 4D printing shape memory material, and the 4D printing shape memory material For 4D printing shape memory polymers or 4D printing shape memory polymer composite materials, the temporary state of the protective sleeve 8 is a compressed state, which can shrink to a certain extent, and expands after implantation to automatically return to its original shape, The protective cover 8 expands under body temperature conditions until the shape completely fits the inner wall of the bone groove and does not change.

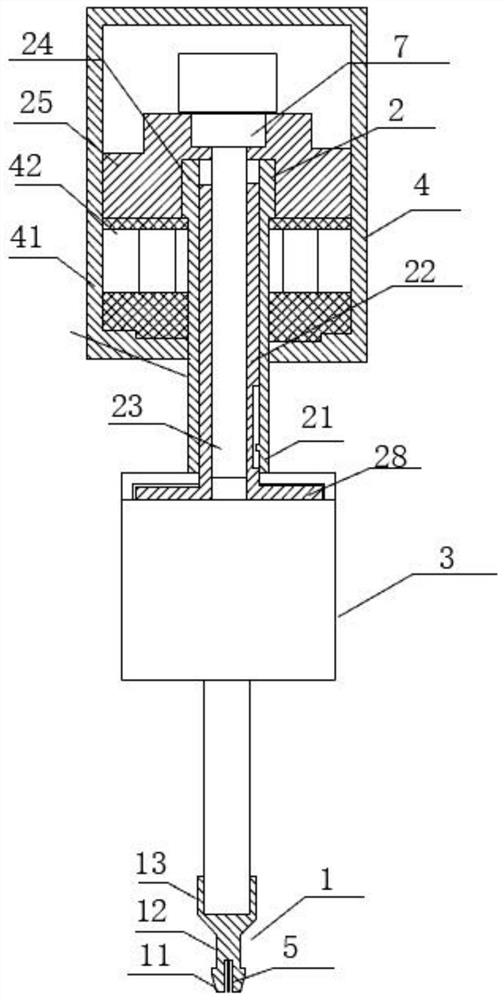

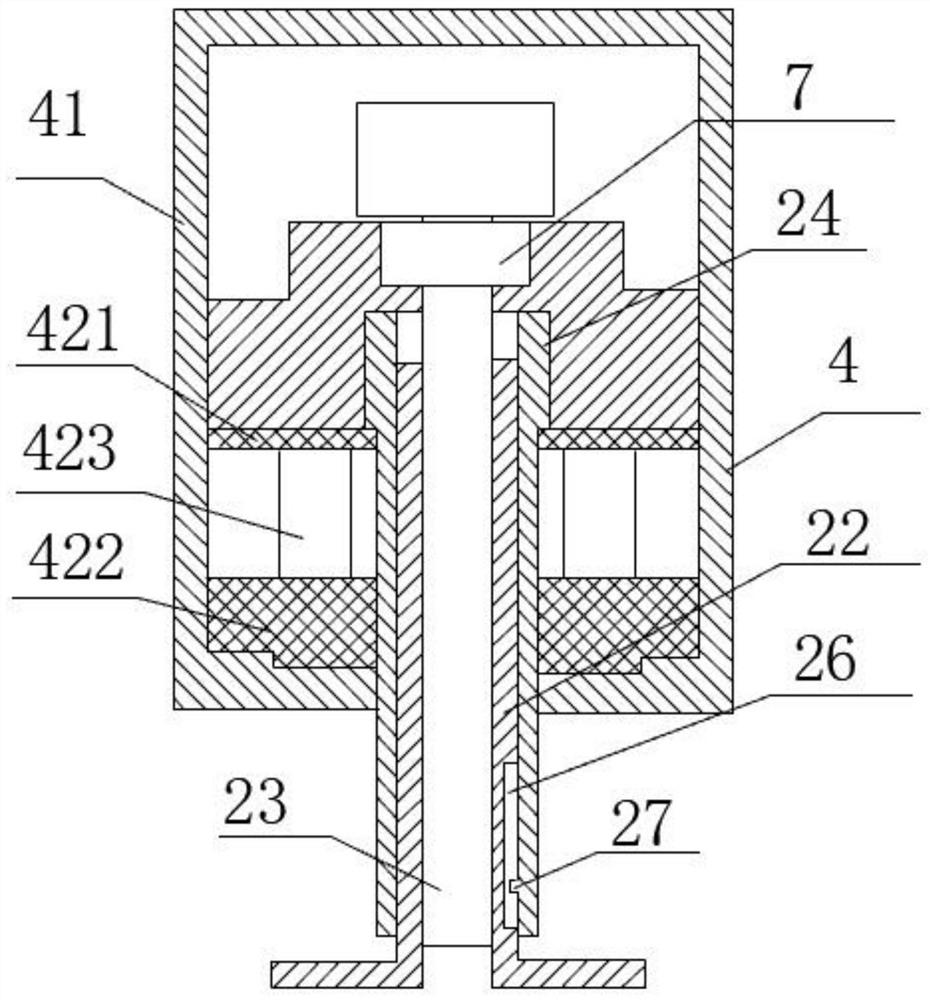

[0034] like figure 2 As shown, in this embodiment, the hearing aid body includes an implant device 1, a propulsion device 2, a vibrator 3, a mounting device 4 and a driving device. The implant device 1 is used for fixed connection with the o...

Embodiment 2

[0039] The 4D printing shape memory polymer in the present invention uses a UV-LED stereotactic printer, and uses 10,000 g / mol methacrylated polycaprolactone as the printing material for printing.

[0040] The 4D printing process includes:

[0041] (a) digital model is created from MRI scans (holes, grooves);

[0042] (b) building a 3D model;

[0043] (c) Printing with a UV-LED stereotactic printer;

[0044] (d) Obtaining the product.

[0045] The protective cover prepared by 4D printing shape memory polymer, the Tg of methacrylated polycaprolactone is 37 ℃, can return to the original shape at body temperature, and can be prepared according to the individual condition of the patient's surgical incision, which not only solves the problem of It is difficult to fit the hearing aid equipment and the skull tightly, and this kind of protective sleeve does not need to be fixed on the wall of the bone groove through surgical traction, but directly achieves the effect of tight fitti...

Embodiment 3

[0047] The difference between this embodiment and the above-mentioned embodiments is that the shape memory polymer composite material of this embodiment adds short fibers, carbon fibers, and nickel powder on the basis of shape memory polymers; The liquid controls the value of the material to make it deform. We can stimulate it individually or in combination, such as heating; electromagnetic stimulation; due to wearing the hearing aid for a long time, or because it is dropped on the ground, it is prone to cracks. After its stimulation, Effective restoration of this hearing aid. Extend the life of your hearing aids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com