Insert type knurled nut

A technology of embossing and nuts, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve problems such as easy loosening or even falling off, and achieve the effect of enhancing anti-loosening performance, increasing strength, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

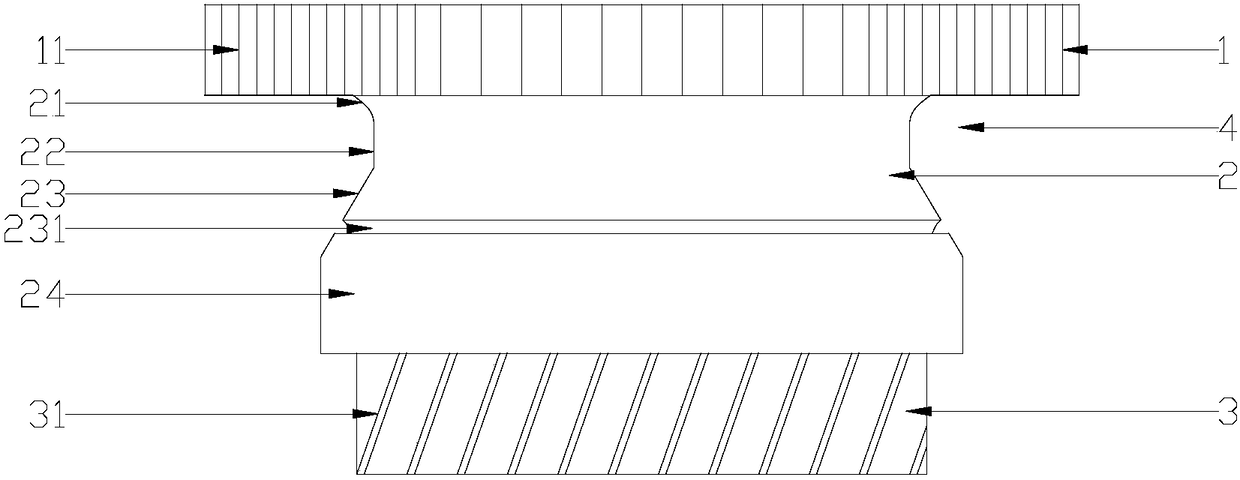

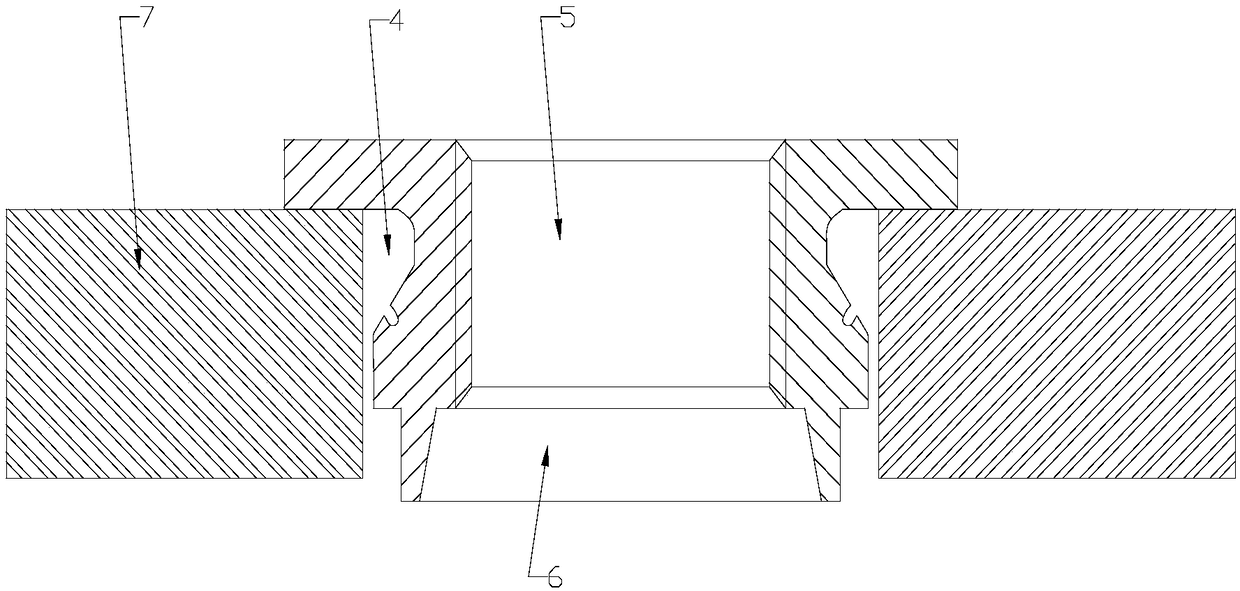

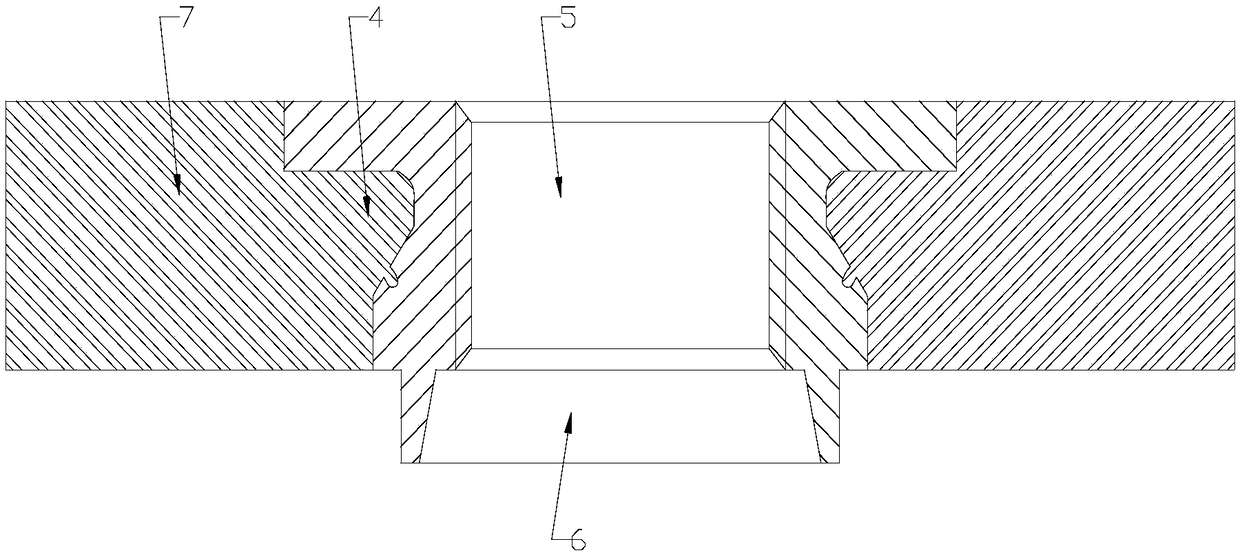

[0018] refer to figure 1 , figure 2 , image 3 and Figure 4 , a sheet-shaped embossed nut according to the present invention, comprising a screw head 1, a nut body 2 and a riveting interface 3, the screw head 1 is a hexagonal screw head, and the upper and lower ends of the nut body 2 are riveted with the screw head 1 and the riveting joint respectively. The mouth 3 is connected, the guide chamber 4 is formed between the screw head 1 and the nut body 2, the first through hole 5 is provided through the screw head 1 and the nut body 2, and the inner wall of the first through hole 5 Internal threads are provided on the rivet interface 3, and a second through hole 6 is arranged in the riveting interface 3. The first through hole 5 communicates with the second through hole 6, and the diameter of the first through hole 5 is smaller than that of the second through hole. 6, the side of the screw head 1 is provided with a first embossing pattern 11, the side of the riveting port 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com