Lithium-sulfur battery

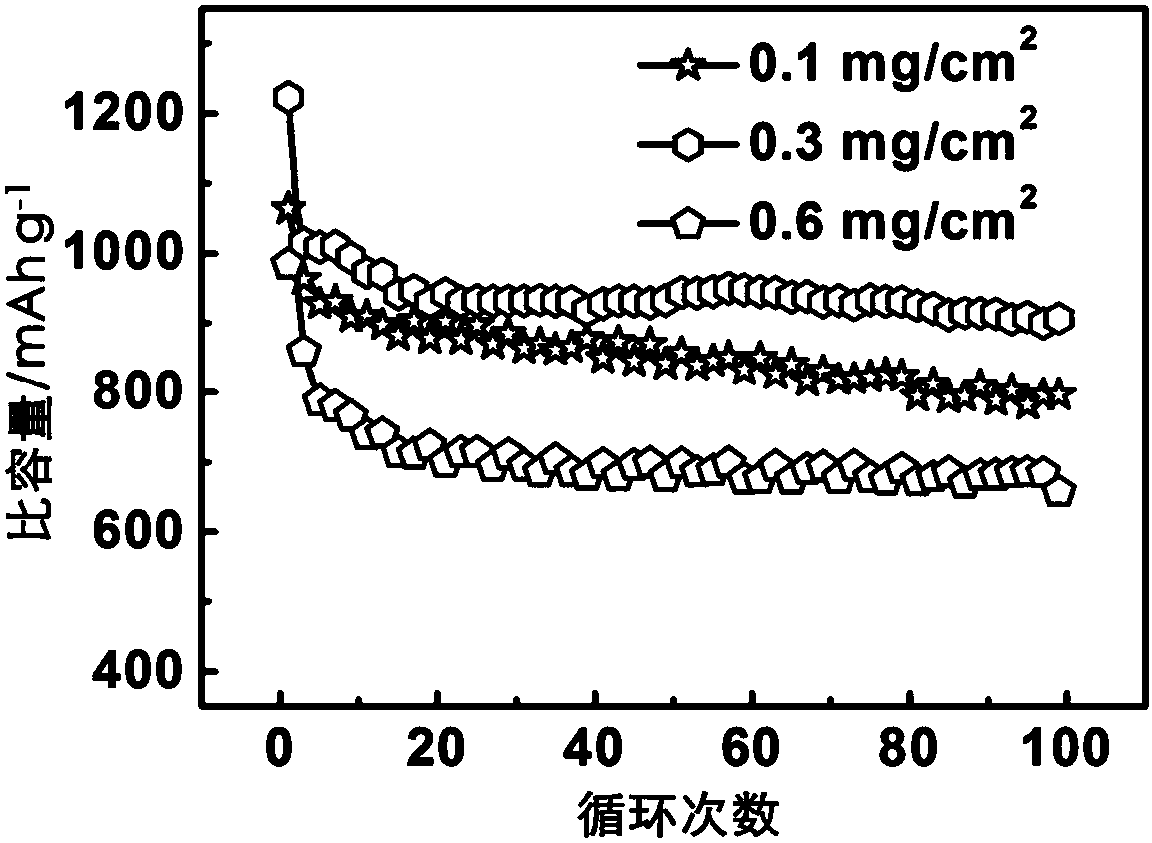

A lithium-sulfur battery and electrolyte technology, which is applied to lithium batteries, secondary batteries, battery pack components, etc., can solve the problems of low specific capacity, irreversible damage to the sulfur-containing structure of the cathode, and poor cycle stability of lithium-sulfur batteries. The effect of enriching electronic pathways and improving transformation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

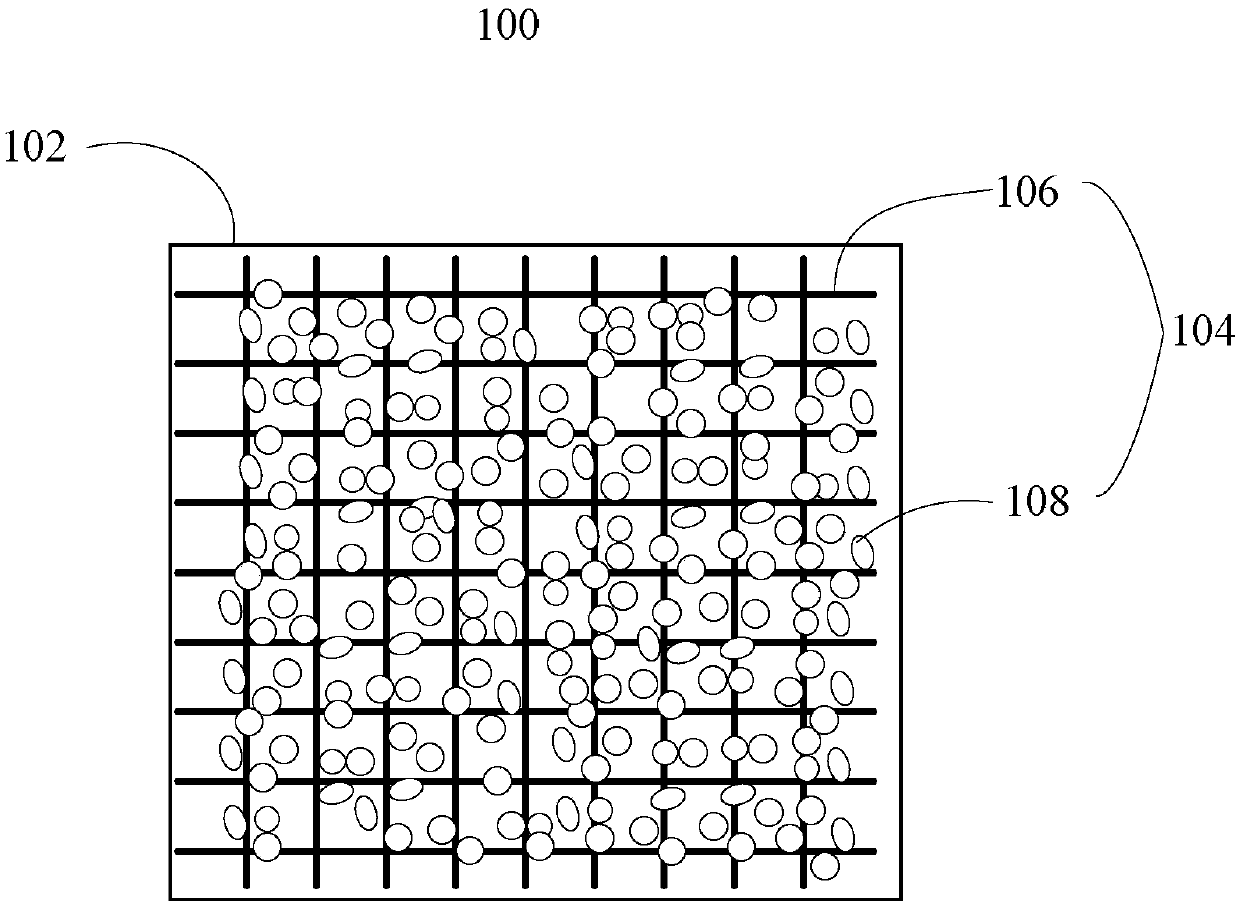

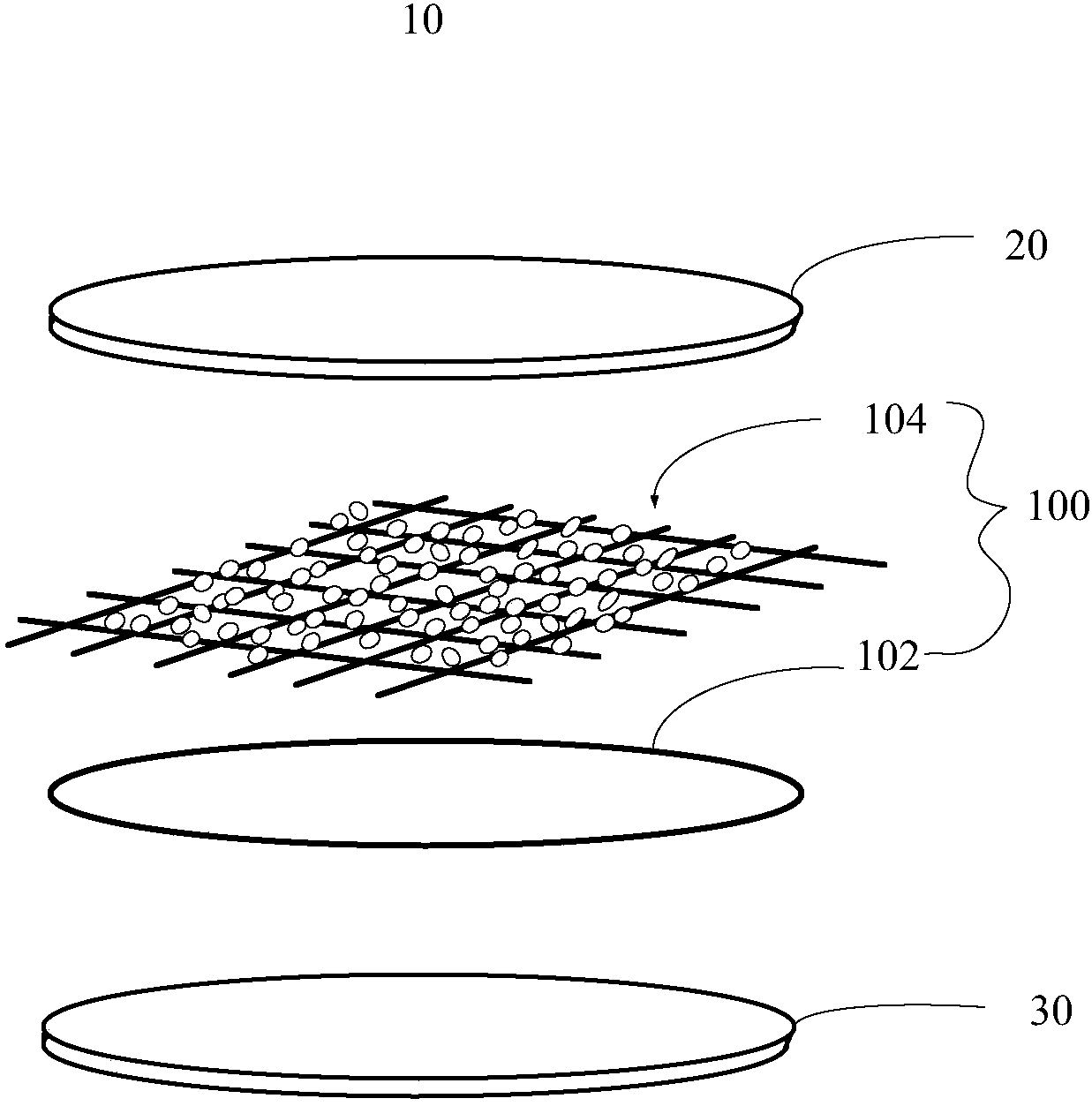

[0041] The preparation method of the lithium-sulfur battery diaphragm 100 includes: providing the basic diaphragm 102; laying the carbon nanotube structure skeleton 106 on the surface of the basic diaphragm 102; 2 The suspension of nanoparticles 108 is uniformly dropped on the carbon nanotube structure skeleton 106, and after drying, a plurality of MoP 2 Nanoparticles 108 are attached to the surface of the carbon nanotubes in the carbon nanotube structure skeleton 106 . The multiple MoPs 2 The nanoparticles 108 are located on the surface of the carbon nanotube framework 106 or filled in micropores of the carbon nanotube framework 106 .

[0042] The lithium-sulfur battery 10 provided by the present invention uses a special diaphragm, that is, the lithium-sulfur battery diaphragm 100 . The lithium-sulfur battery separator 100 includes a basic separator 102 and a functional layer 104 . The functional layer 104 includes a carbon nanotube structure skeleton 106 and a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com