Fabric dust collection device

A technology for dust removal devices and fabrics, applied in washing devices, textiles and papermaking, household appliances, etc., can solve problems such as time-consuming, labor-intensive, physical health effects, inconvenience, etc., and achieve the effect of simplifying the driving structure and avoiding dust scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

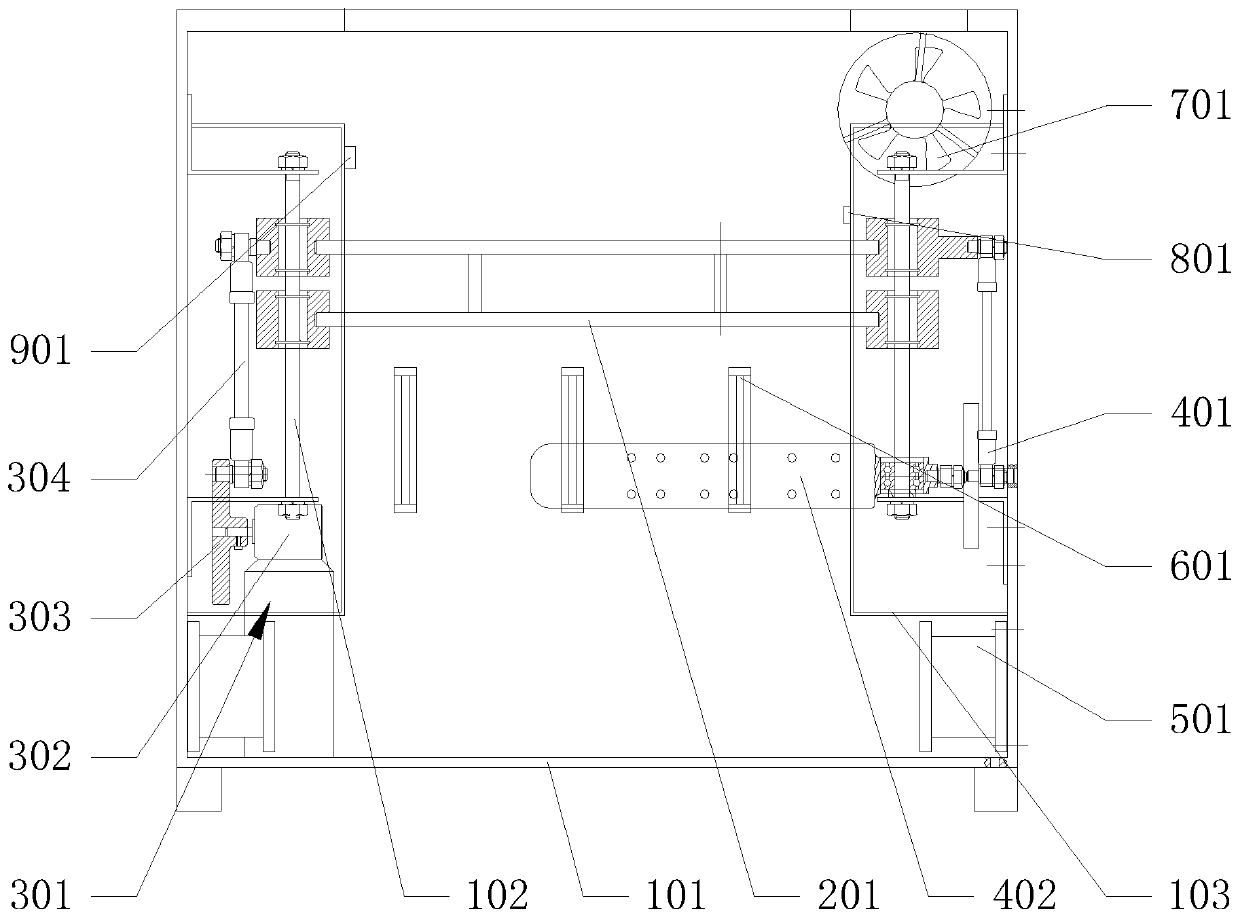

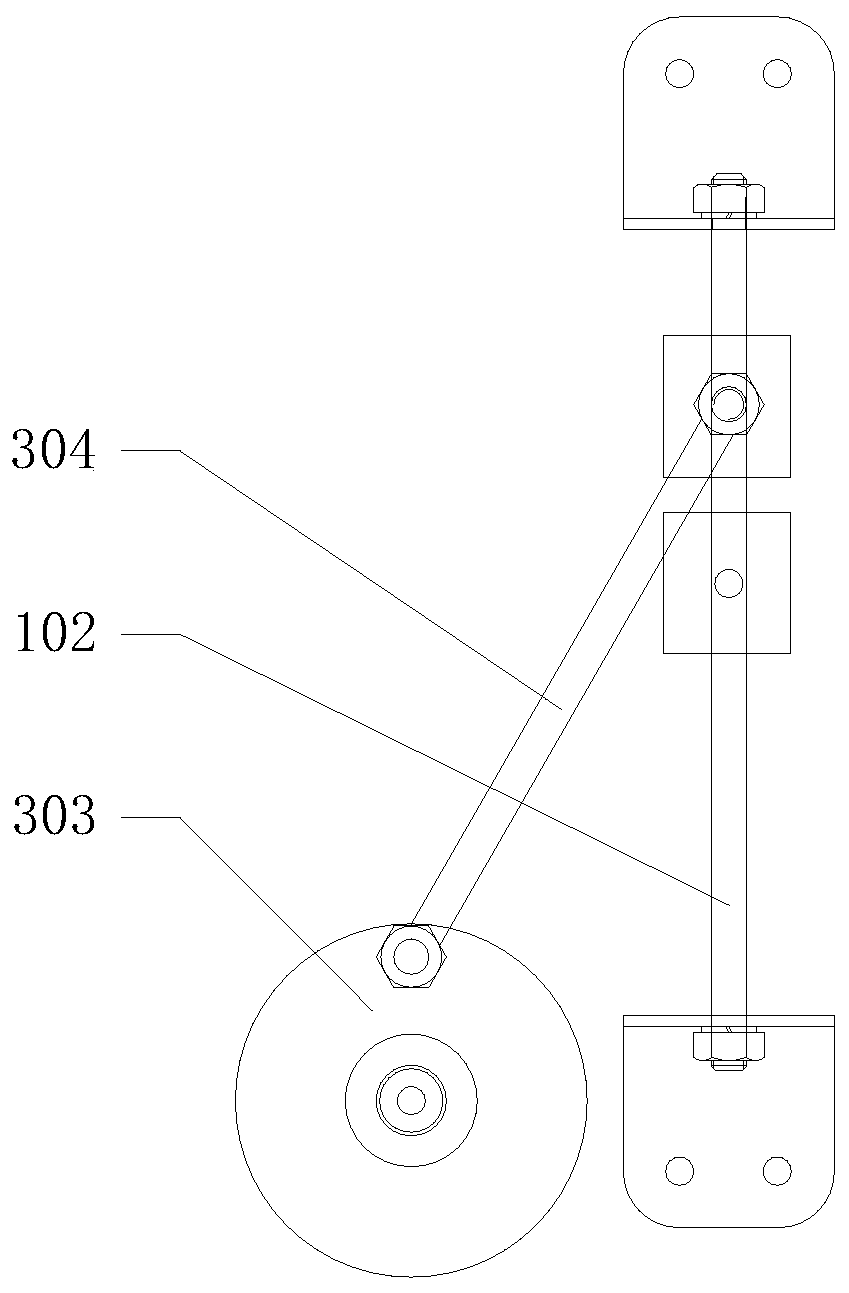

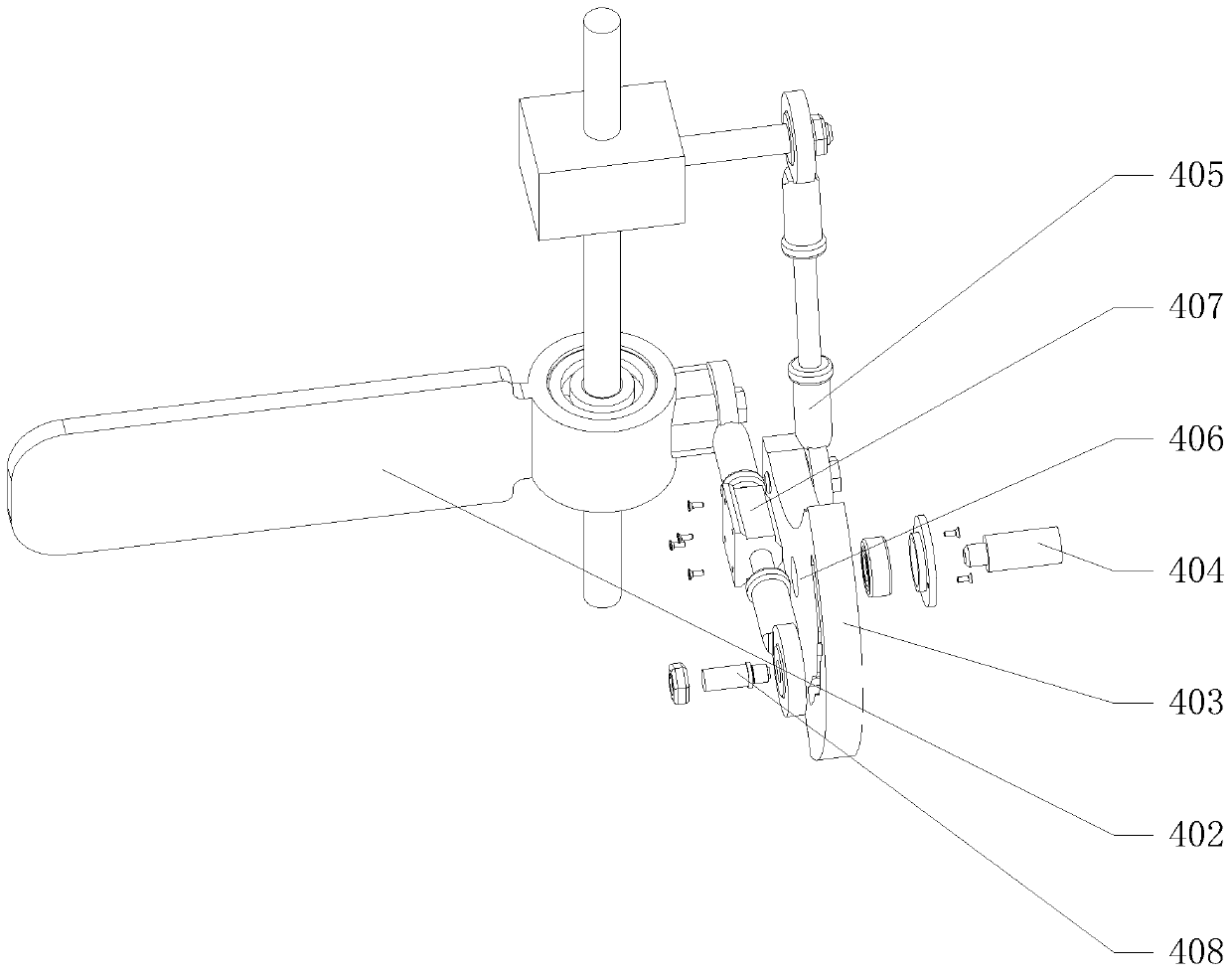

[0034] Please also refer to figure 1 , figure 2 as well as image 3 , this embodiment discloses a fabric dust removal device, which includes a box body 101 , a fabric placement rack 201 , a longitudinal moving assembly 301 and a lateral flapping assembly 401 . The box body 101 is a hollow structure, and the box body 101 is provided with guide rails 102. There are two guide rails 102, and they are vertically arranged on both sides of the box body 101. The two ends of the fabric placement rack 201 are sleeved on the on the guide rail 102 (in this embodiment, the fabric placement rack can be a simple rod structure, and in other embodiments, a fixing clip structure can also be added to the rod to realize the fixing of the textile). Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap