Electrothermal film gravure printing equipment and electrothermal film printing method

A technology of gravure printing and printing method, applied in the field of electrothermal film gravure printing equipment and electrothermal film printing, can solve the problems of no feeding device, poor printing effect, no cooling design, etc., to prevent excessive temperature and be beneficial to performance Stable and mass production, ensuring the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

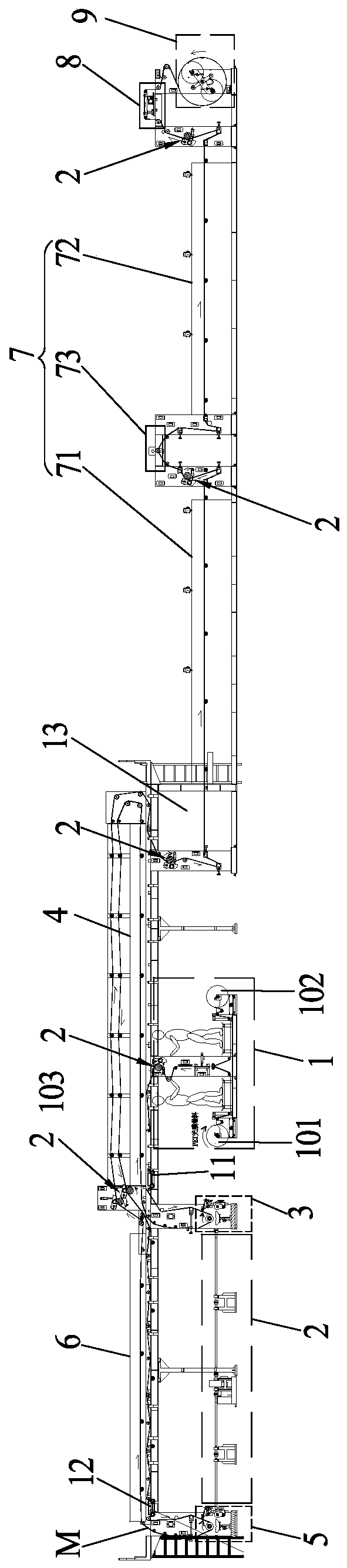

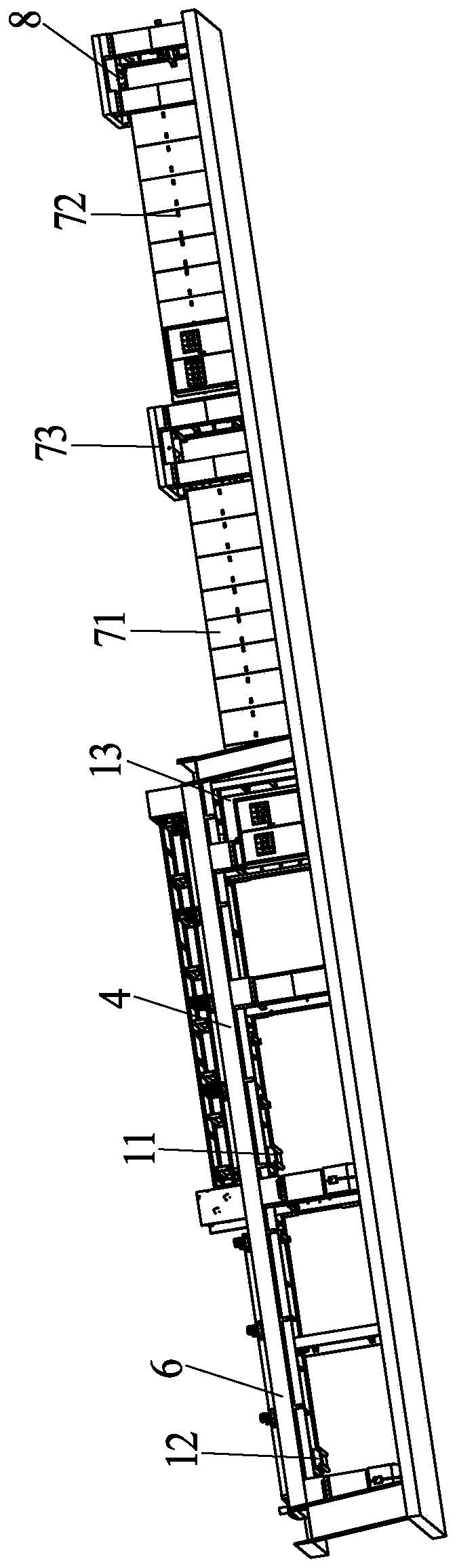

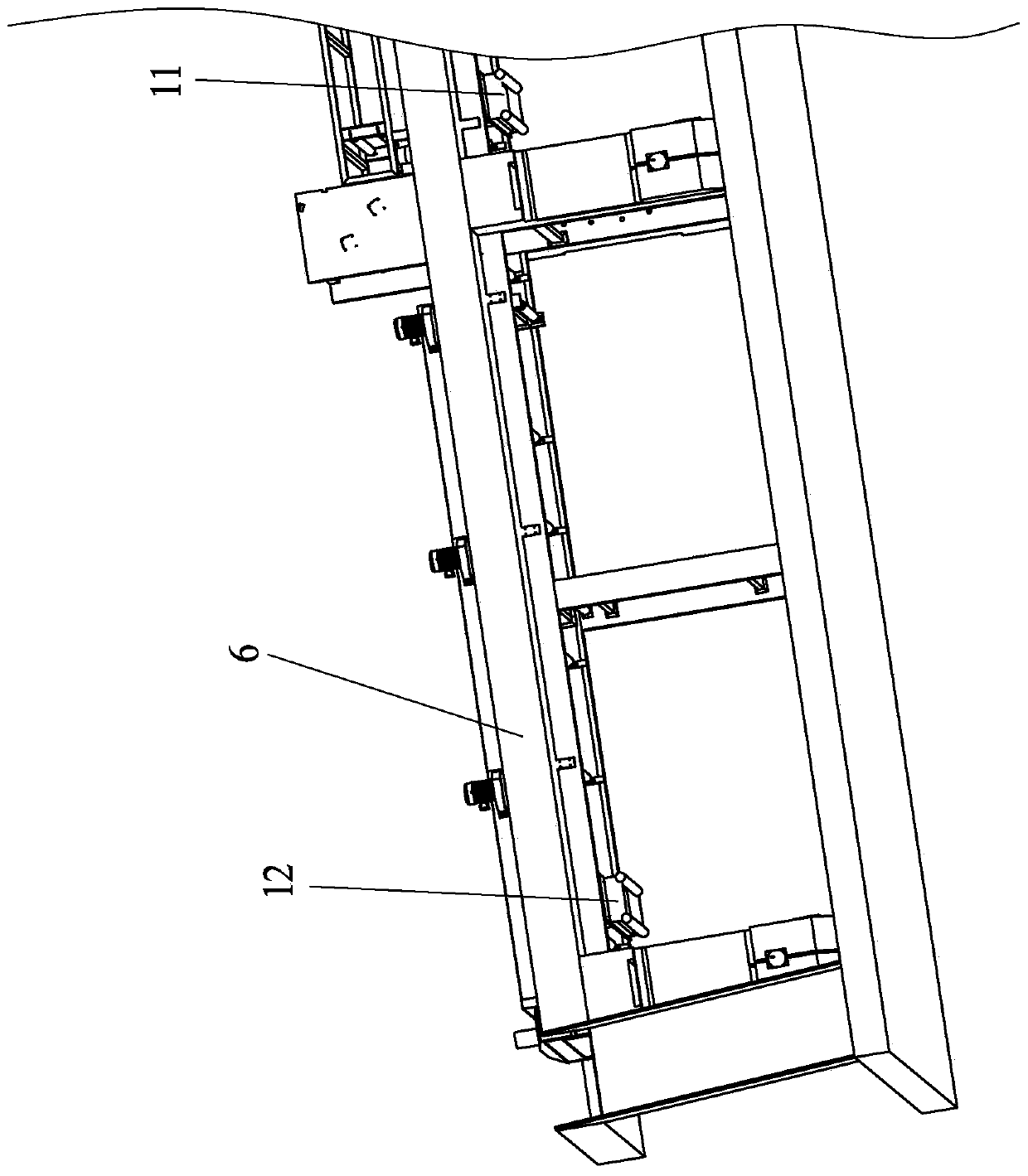

[0027] see figure 1 with figure 2 , The invention discloses an electrothermal film gravure printing equipment, comprising a feeding correction device 1, a carbon paste roller printing device 3, a first drying channel device 4, a silver paste roller printing device 5, a second drying channel device 6, a first Three drying channel devices 7, the first fan cooling device 8, the automatic winding device 9 and the roller transmission system 2, the feeding and correcting device 1 is used to load and transport the light film, the carbon paste roll printing device 3, the first drying channel Device 4, silver paste roller printing device 5, second drying channel device 6, third drying channel device 7 and first fan cooling device 8 are sequentially arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com