Large-capacity air-cooled steam turbine generator stator bar end part curing process

A technology for turbogenerators and stator wire rods, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve problems such as low work efficiency, affecting the effect of end curing, thermal expansion and contraction of wire rods, etc. , to achieve excellent curing effect, reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

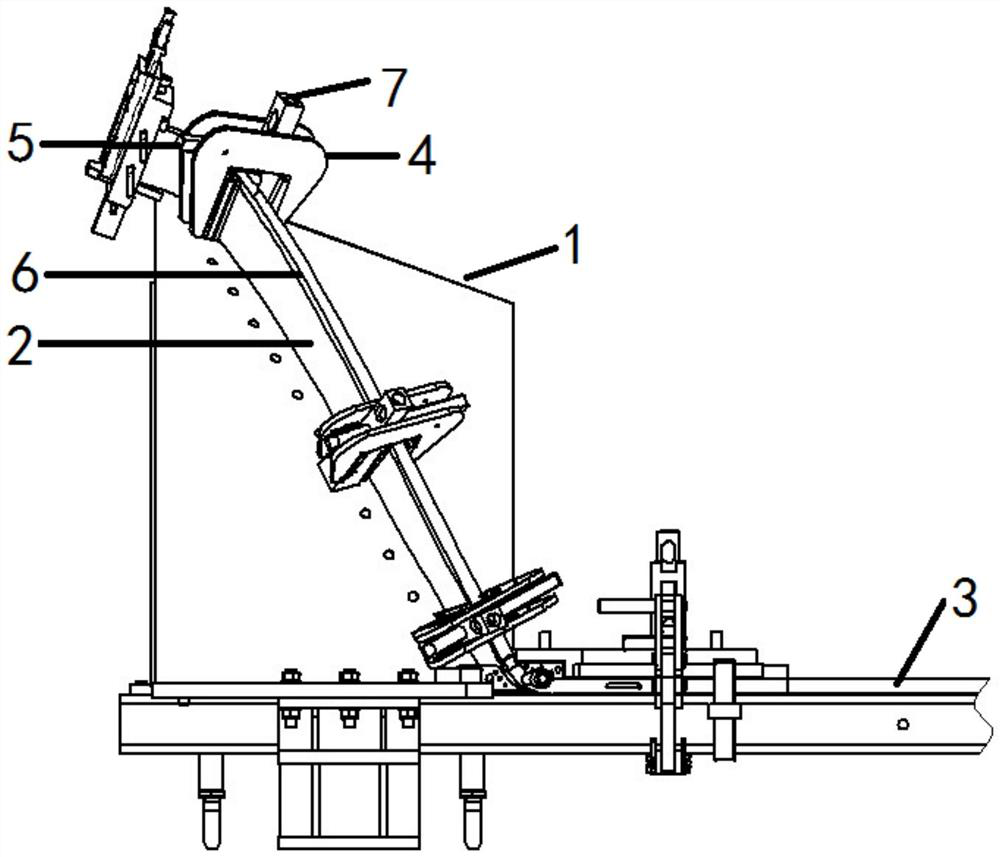

Image

Examples

Embodiment

[0028] Below in conjunction with the 300MW generator stator bar example, the concrete steps of implementing the present invention are further introduced:

[0029] (1) According to the requirements of the drawings, put the length of the involute at the end of the stator bar 2 into the inter-row insulation, and wrap it with 1 / 3 of the release tape; the length of the involute is the part where the end of the bar extends out of the stator core The length of the strip; 1 / 3 lapping of the release tape means that when the release tape is wrapped, it overlaps 1 / 3 of the bandwidth;

[0030] The inter-row insulation between multiple sections cannot be lapped, and the interval between the insulation between the rows of each section cannot exceed 5mm, and the outer 1 / 3 part of the insulation between the rows at the end of the wire rod should be cut into a V-shaped mouth to adapt to the gradual change at the end of the wire rod The shape of the opening part needs to be bent;

[0031] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com