Automotive Air Conditioning System Using Secondary Circuit

A secondary circuit and pre-vehicle technology, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of too small heat exchange area of the cold core and insufficient cooling capacity, and achieve the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

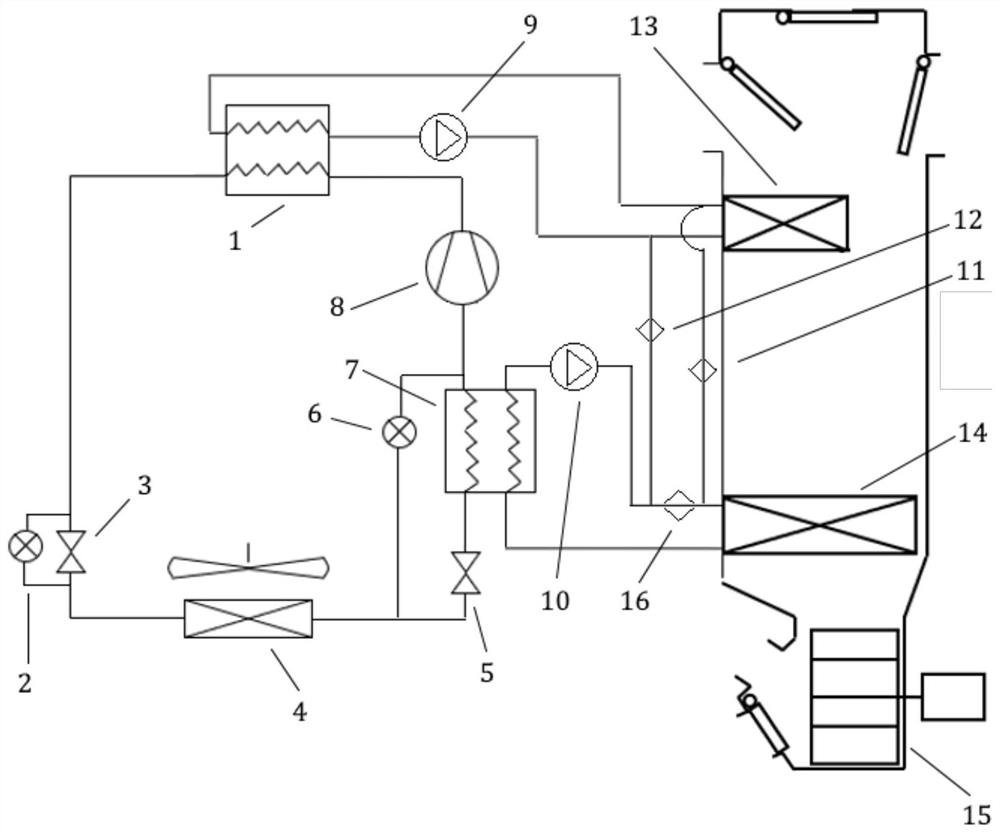

[0022] like figure 1 As shown, it is an automobile air-conditioning system using a secondary circuit involved in the present invention, including: a condensing plate heat exchanger 1, a compressor 8, an evaporating plate heat exchanger 7, and a front heat exchanger connected in sequence to form a loop 4, wherein: the first ball valve 2 and the first expansion valve 3 connected in parallel are arranged between the condensing plate heat exchanger 1 and the front heat exchanger 4, and the evaporating plate heat exchanger 7 and the front heat exchanger 4 are arranged There is a second expansion valve 5, the front heat exchanger 4 and the compressor 8 are further connected through a second ball valve 6, and the condensing plate heat exchanger 1 and the evaporating plate heat exchanger 7 are respectively connected to the warm core 13 and the cold core 14 .

[0023] The input end and output end of the condensing plate heat exchanger 1 are connected to the warm core 13, the input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com