Patents

Literature

35results about How to "Solve technical problems with poor compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

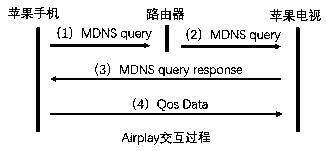

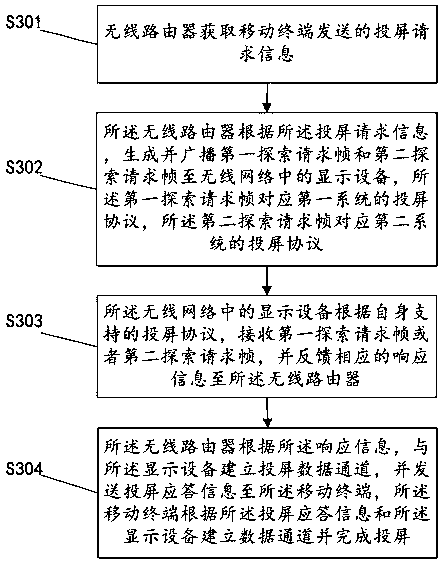

Wireless screen projection method and wireless router

InactiveCN108399056ASolve technical problems with poor compatibilityImprove experienceConnection managementDigital output to display deviceWireless routerComputer terminal

The invention discloses a wireless screen projection method, which comprises the following steps that: a wireless router obtains screen projection request information sent from a mobile terminal; thewireless router generates and broadcasts a first exploration request frame and a second exploration request frame to display equipment in the wireless network according to the screen projection request information, wherein the first exploration request frame corresponds to the screen projection protocol of a first system, and the second exploration request frame corresponds to the screen projection protocol of a second system; the display equipment in the wireless network receives the first exploration request frame or the second exploration request frame according to own supported screen projection protocol, and feeds back the corresponding response information to the wireless router; and the wireless router establishes a screen projection data channel with the display equipment accordingto the response information, and sends the screen projection response information to the mobile terminal, wherein the mobile terminal establishes a data channel according to the screen projection response information and the display equipment and finishes screen projection, and the technical problem that the wireless screen projection is incompatible is solved.

Owner:SHANGHAI KANGFEI INFORMATION TECH CO LTD

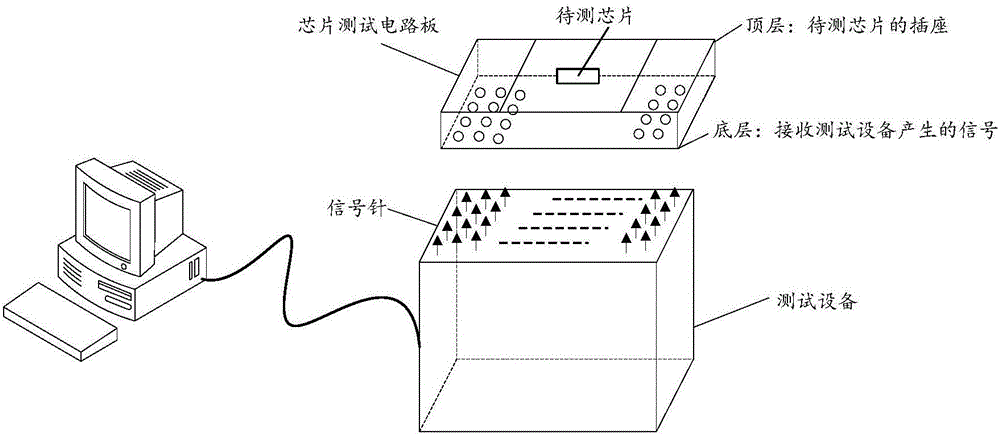

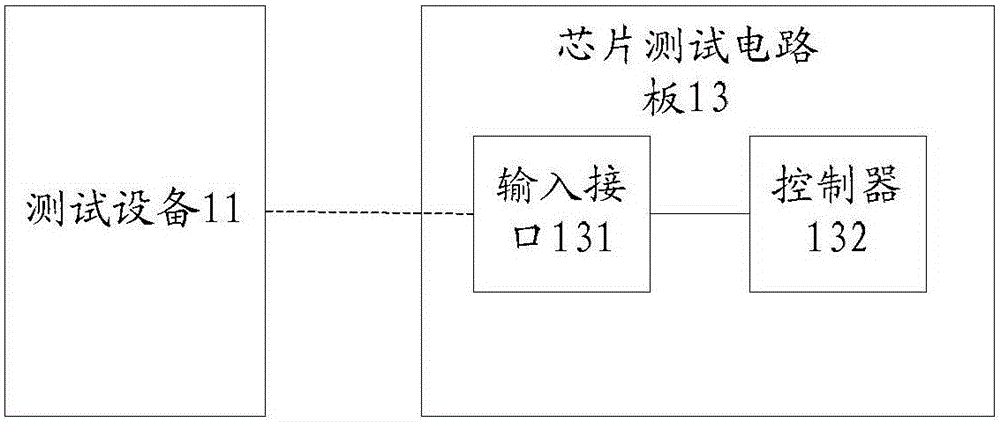

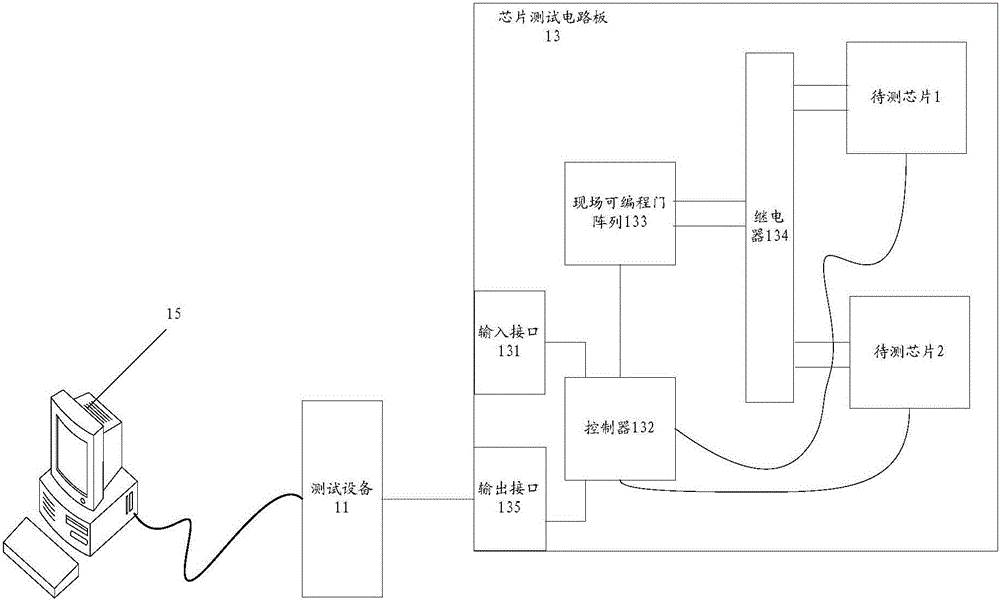

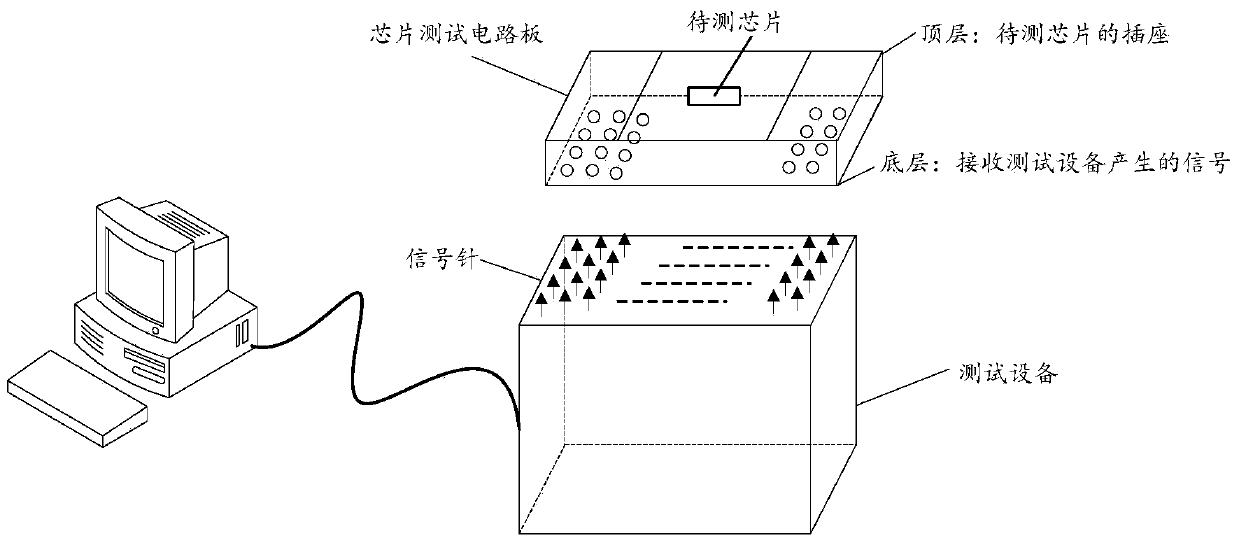

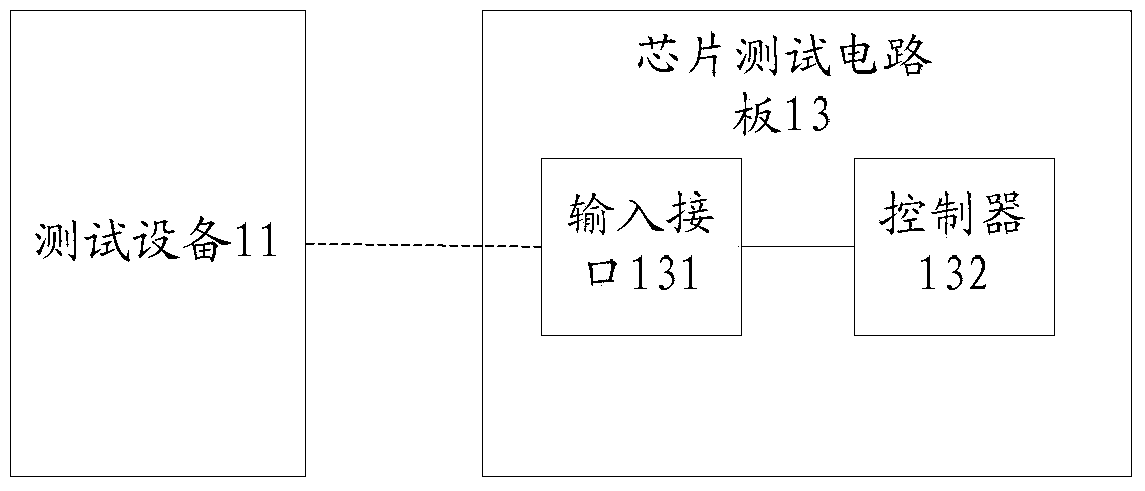

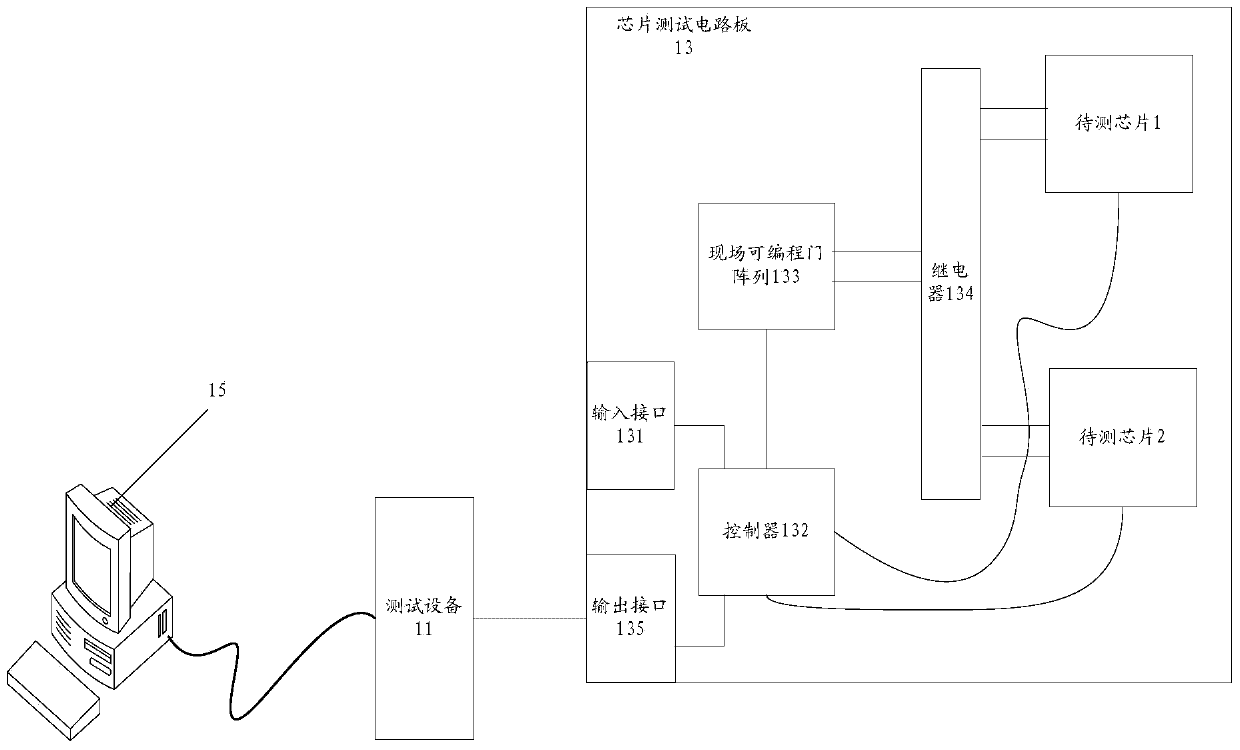

Chip test method and chip test device

ActiveCN105911451AFast test resultsImprove compatibilityProgramme controlComputer controlData transmissionTest equipment

The invention discloses a chip test method and a chip test device. The chip test device comprises the test equipment, a chip test circuit board, an input interface which is arranged on the chip test circuit board, is connected with the test equipment and is used for carrying out data transmission between the test equipment and the chip test circuit board, and a controller which is arranged on the chip test circuit board, is connected with a to-be-tested chip and the input interface, is used for acquiring a state instruction of the input interface and determining a corresponding test vector according to the state instruction, wherein the controller is further used for sending a work mode corresponding to the test vector to the to-be-tested chip to make the to-be-tested chip operate in a work mode, the controller is further used for acquiring a work state of the to-be-tested chip operating in the work mode and determining a detection result of the to-be-tested chip according to the work state. Through the method and the device, a technical problem of poor compatibility existing in a chip test device in the prior art is solved.

Owner:ANALOGIX SEMICON (SUZHOU) INC +1

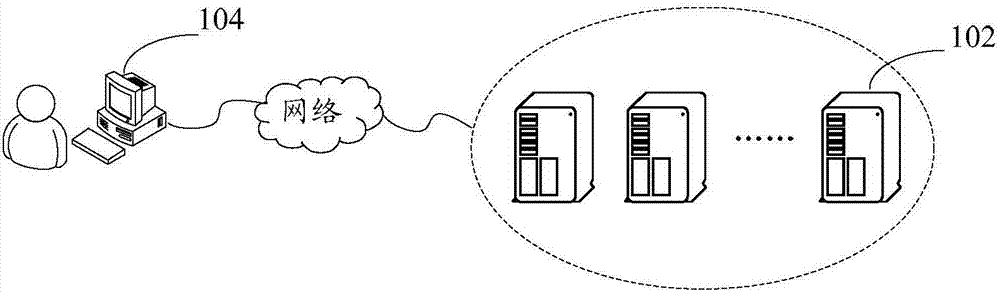

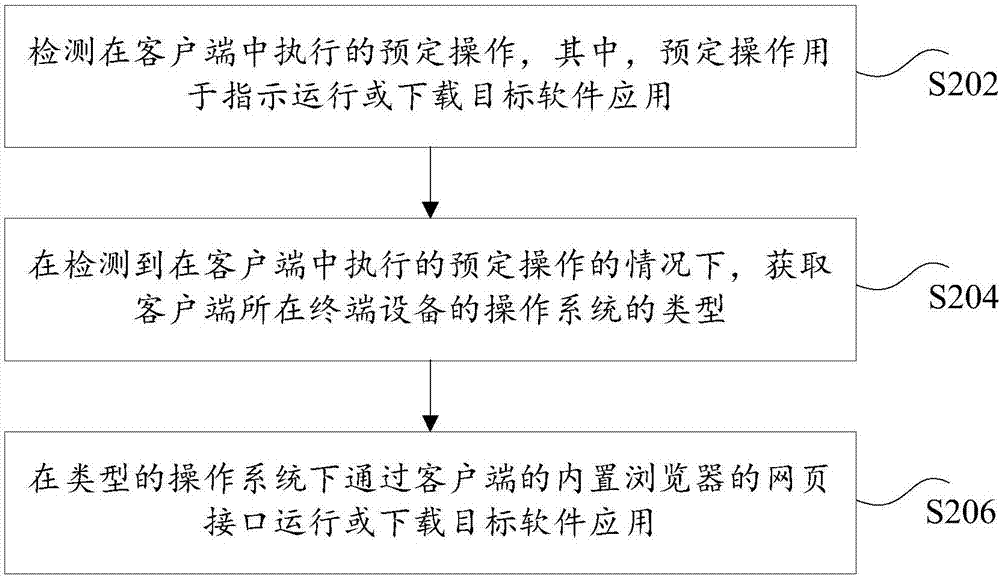

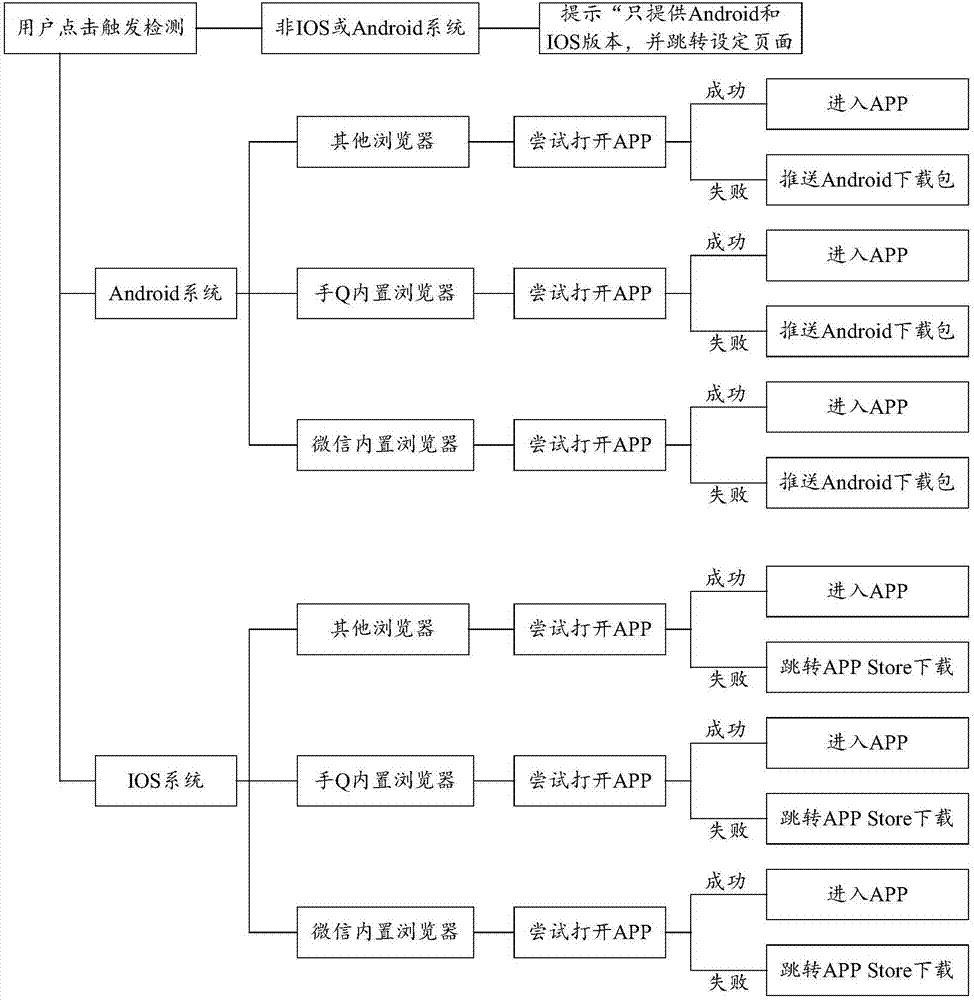

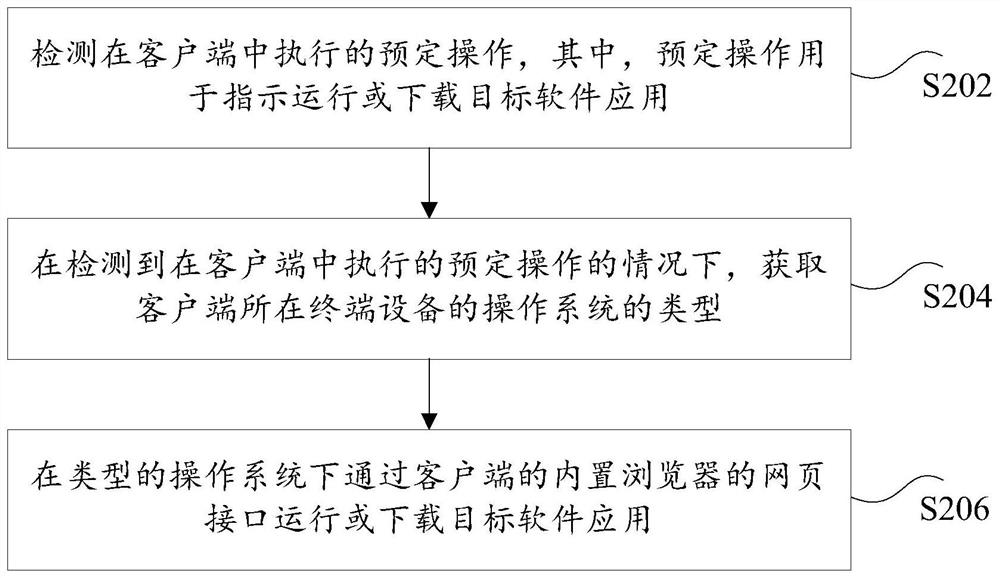

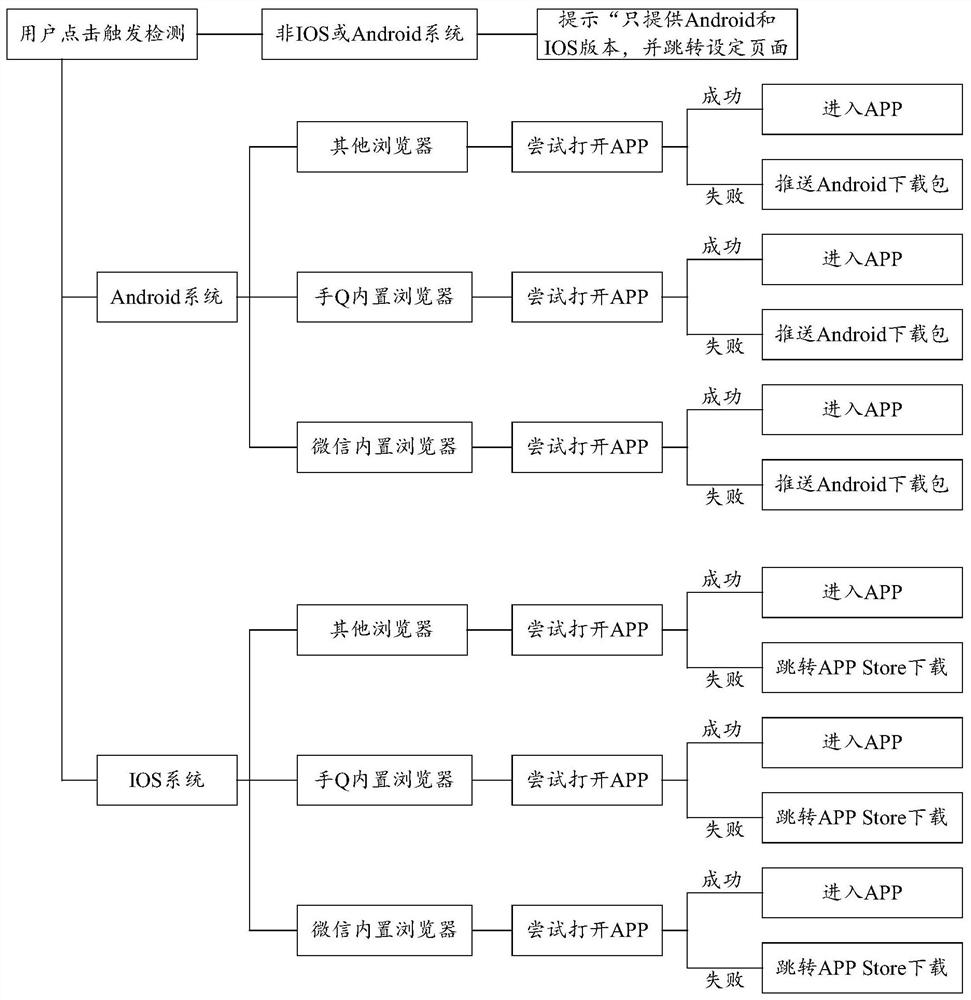

Software application processing method and device

ActiveCN107370804ASolve technical problems with poor compatibilityImprove compatibilityTransmissionOperational systemSoftware engineering

The invention discloses a software application processing method and device. The method comprises the following steps of detecting a scheduled operation executed in a client, wherein the scheduled operation is used for instructing running or downloading of a target software application; obtaining the type of an operating system of terminal equipment where the client is located when the schedule operation executed in the client is detected; and running or downloading the target software application under the operating system of the type through a web interface of an internal browser of the client. According to the method and the device, the technical problem of poor compatibility between the application pushed to a user and the terminal equipment used by the user in the correlation technique is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

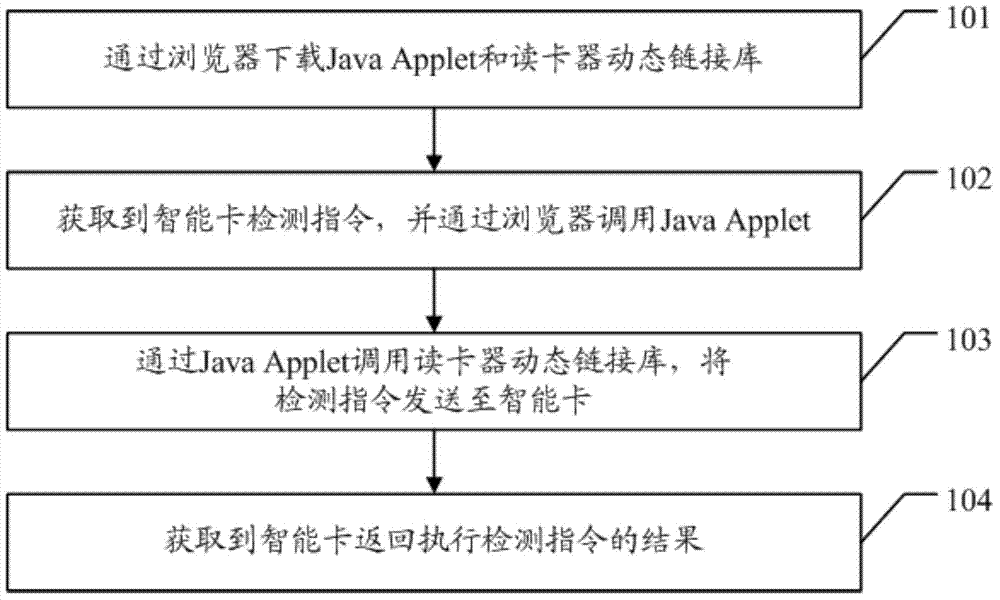

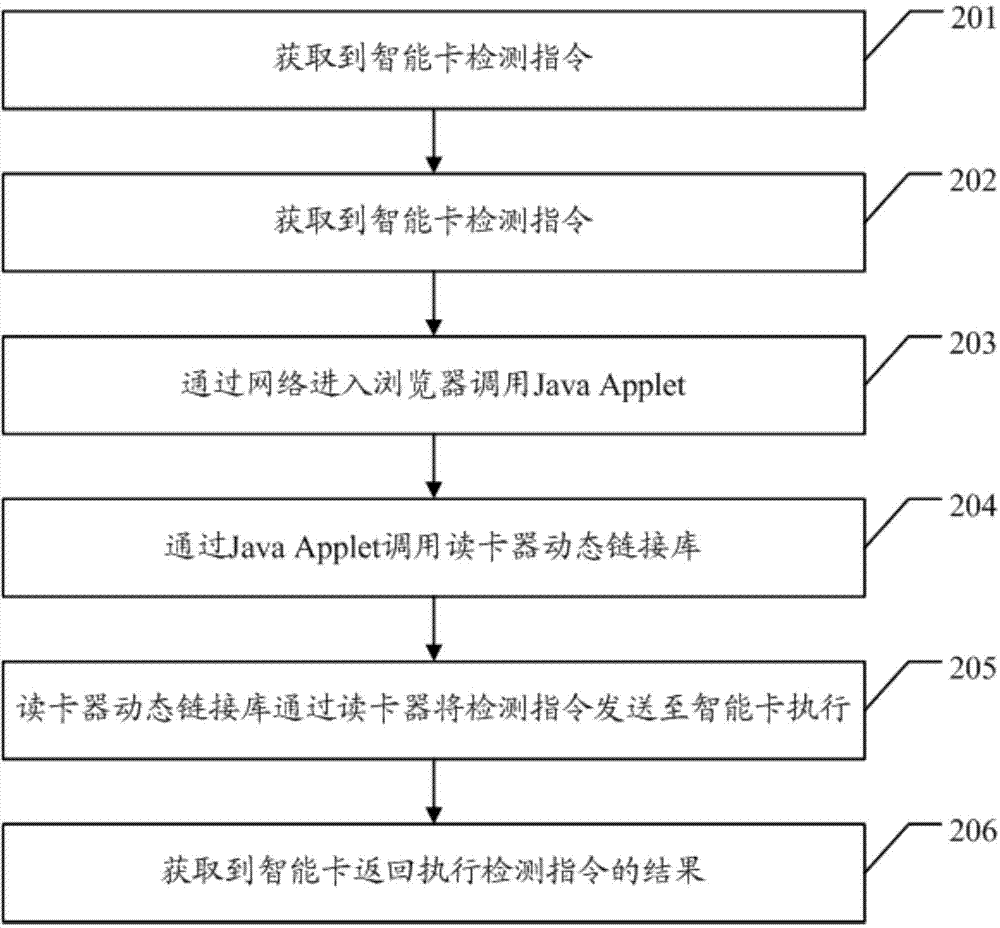

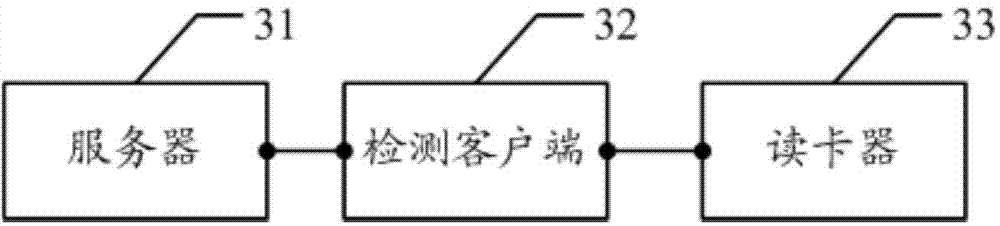

Method and system for detecting intelligent card in cross-platform way

InactiveCN104714890ARealize detectionAchieve normal operationSoftware testing/debuggingSensing record carriersThe InternetComputer compatibility

The embodiment of the invention provides a method and a system for detecting an intelligent card in a cross-platform way, which can solve the technical problems that a control only can be run on an internet explorer browser of a windows platform and then the compatibility of the control and the internet explorer browser is poor, and can avoid the technical problems that the safety is low due to the bug of the windows system. The method for detecting the intelligent card in the cross-platform manner comprises the following steps: acquiring an intelligent card detection instruction, and calling a Java Applet by virtue of the browser; calling a card reader dynamic link base by virtue of the Java Applet, and transmitting the detection instruction to the intelligent card; acquiring a result for executing the detection instruction returned by the intelligent card by virtue of the network. By adopting the method and system, the compatibility of the intelligent card detection system can be improved, and the safety of the operation system can be improved.

Owner:EASTCOMPEACE TECH

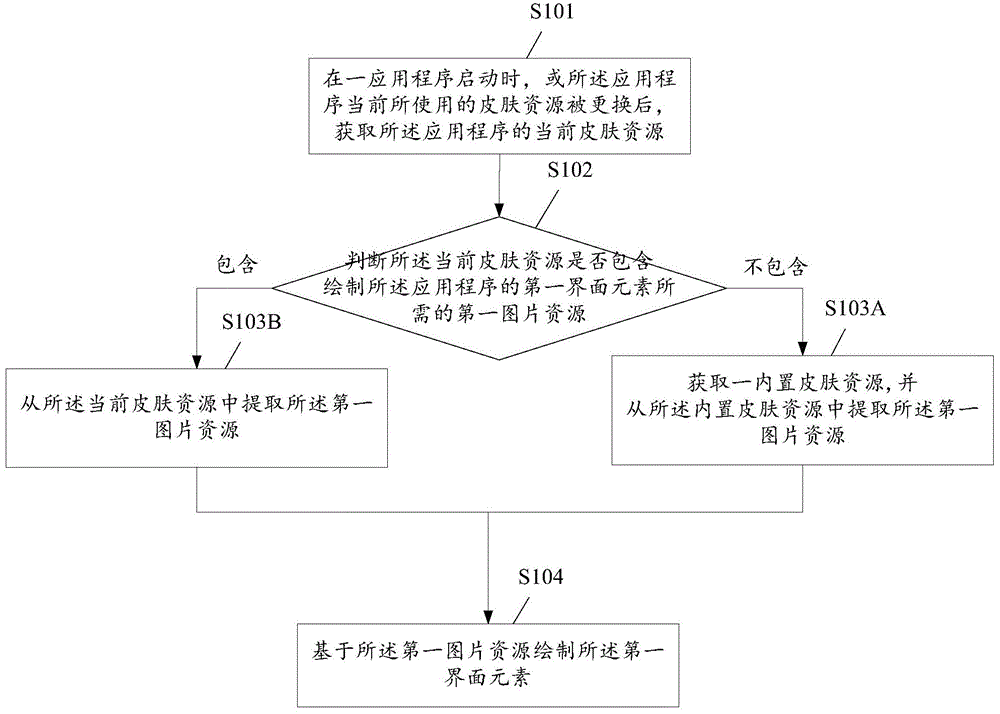

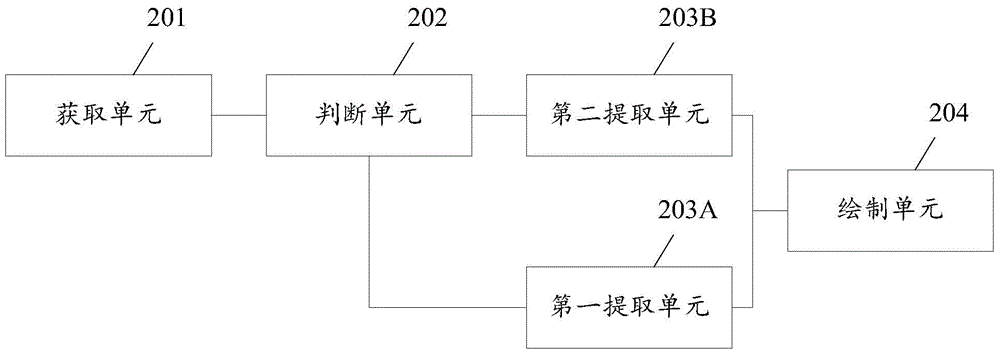

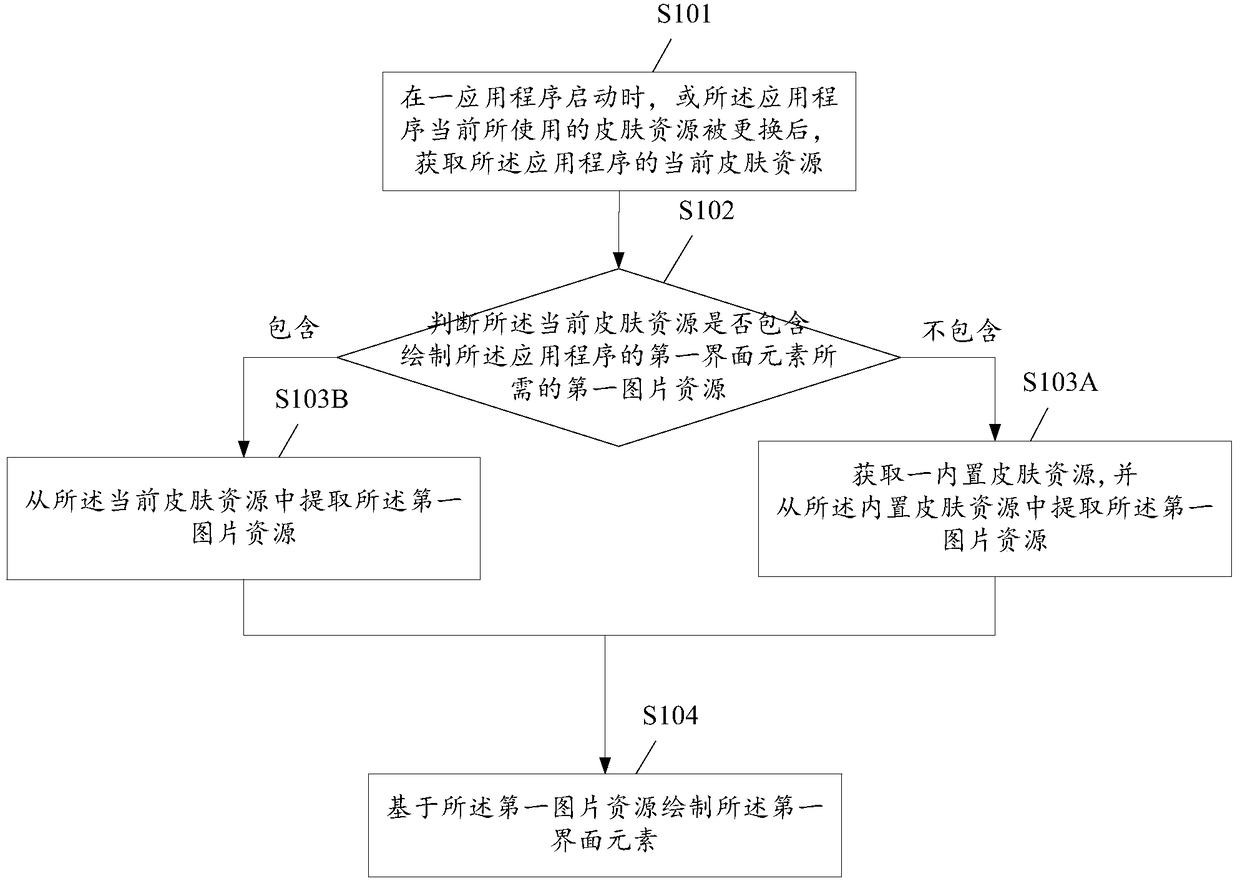

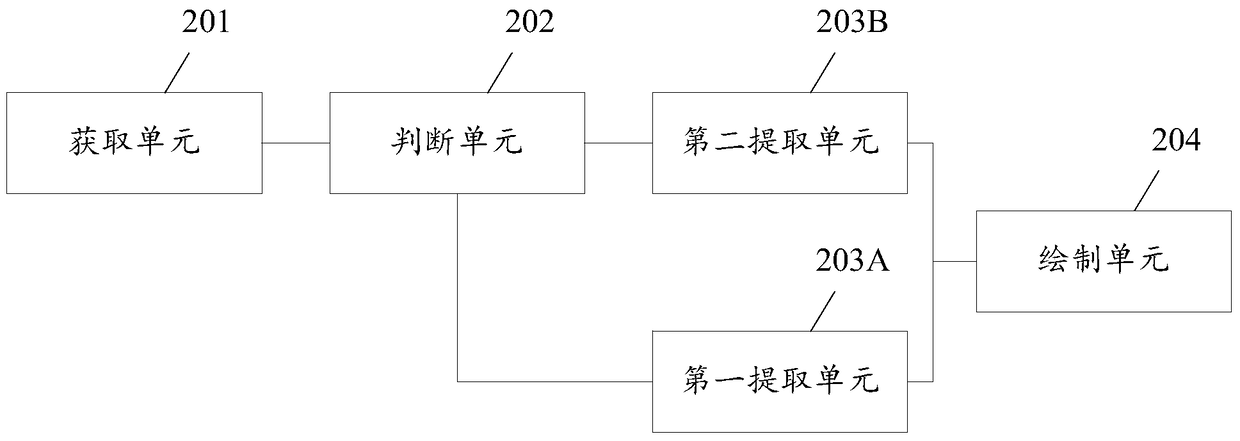

Skin resource processing method and electronic equipment

ActiveCN104461615AImprove compatibilitySolve technical problems with poor compatibility2D-image generationProgram loading/initiatingElectric equipmentElectronic equipment

The invention discloses a skin resource processing method which is applied in electronic equipment. The method comprises the steps of obtaining a current skin resource of an application program; judging whether the current skin resource contains a first image resource or not, wherein the first image resource is needed when a first interface element of the application program is drawn, the application program comprises a plurality of interface elements, and the first interface element is any one of the interface elements; when the current skin resource does not contain the first image resource, obtaining a built-in skin resource, and extracting the first image resource from the built-in skin resource; drawing the first interface element on the basis of the first image resource. The invention further discloses the electronic equipment.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

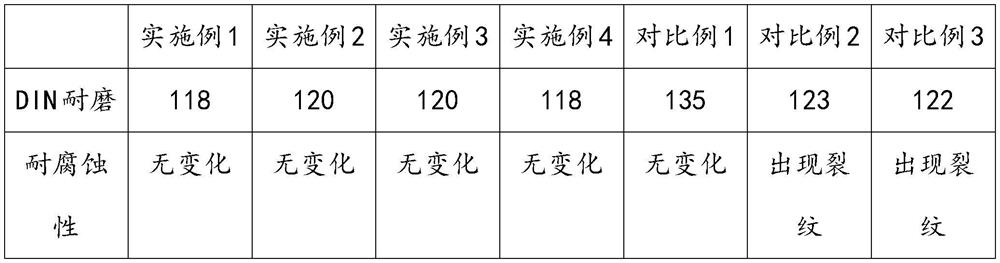

Wear-resistant sole material and preparation method thereof

InactiveCN112375262ASolve technical problems with poor compatibilityImprove corrosion resistanceSolesPolymer scienceCarvacryl acetate

Owner:台州市路桥区静荷纺织有限公司

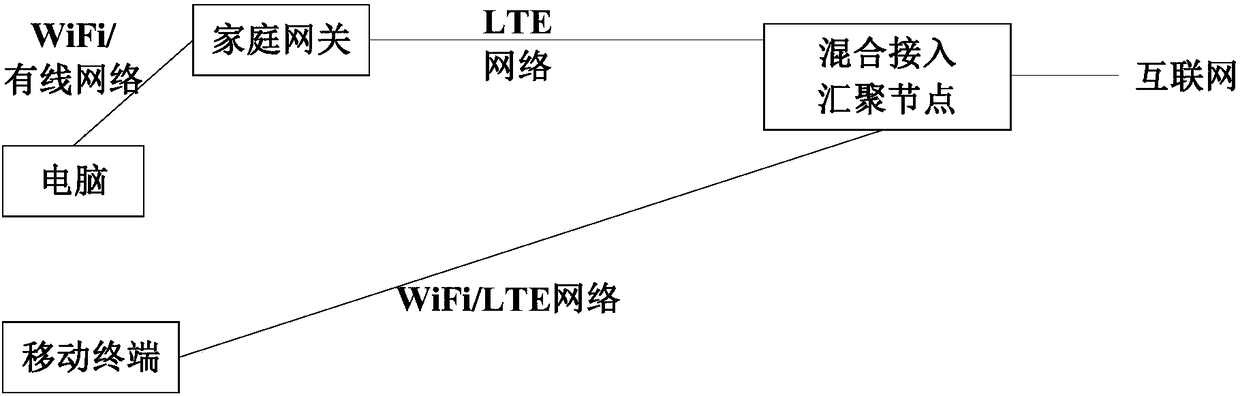

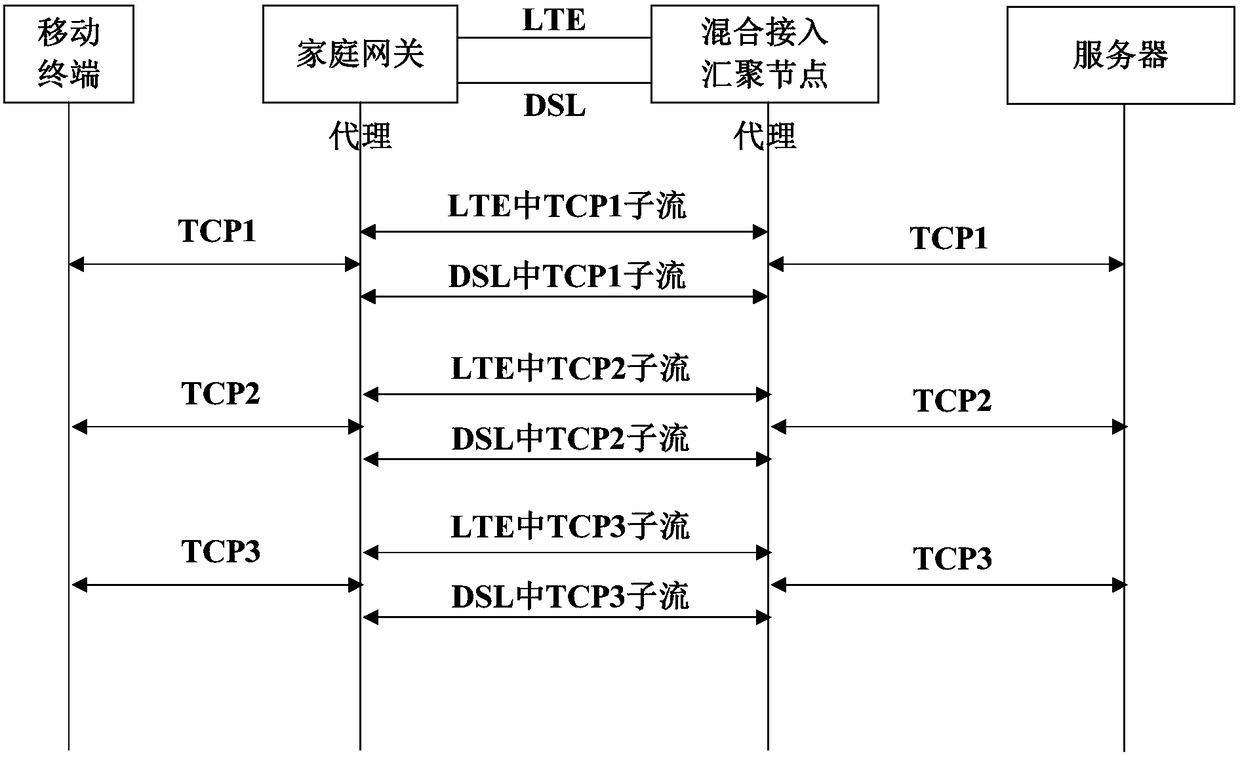

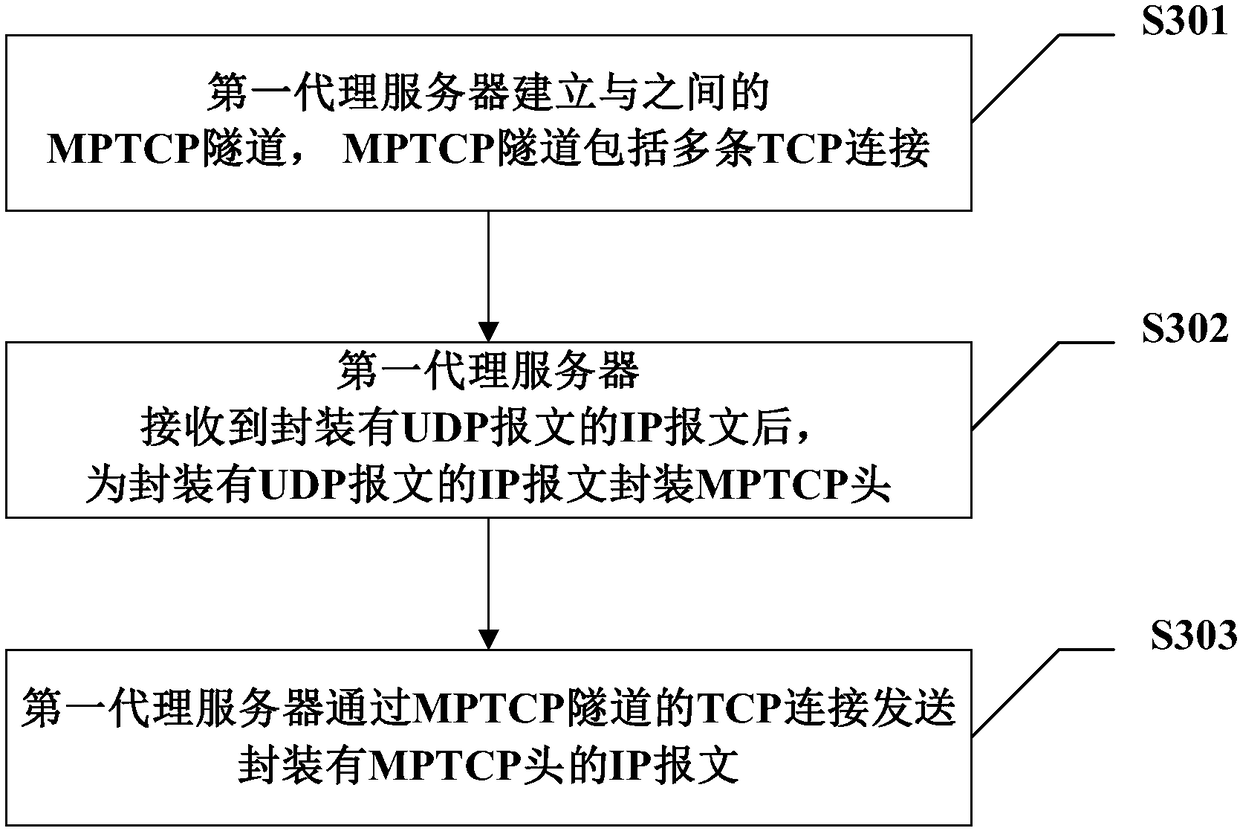

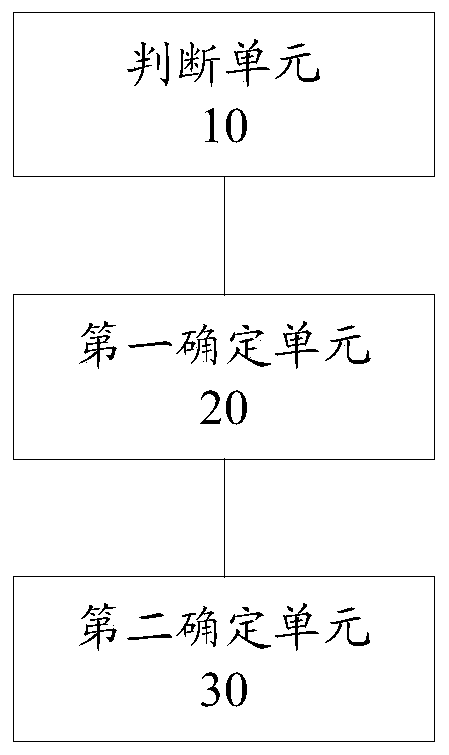

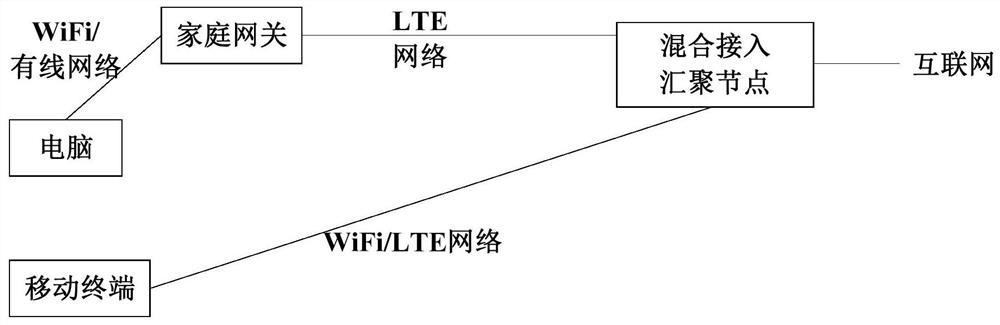

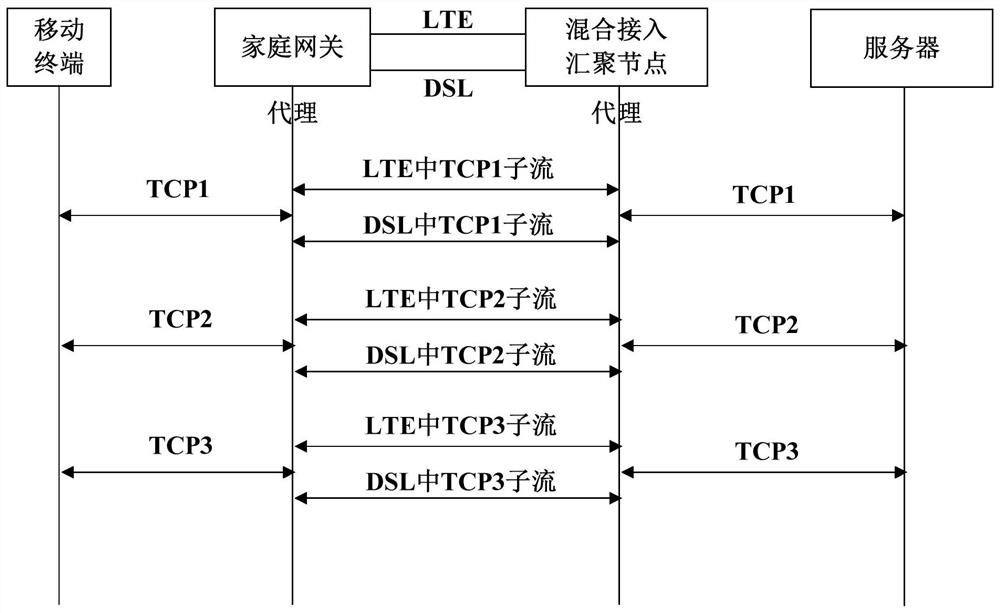

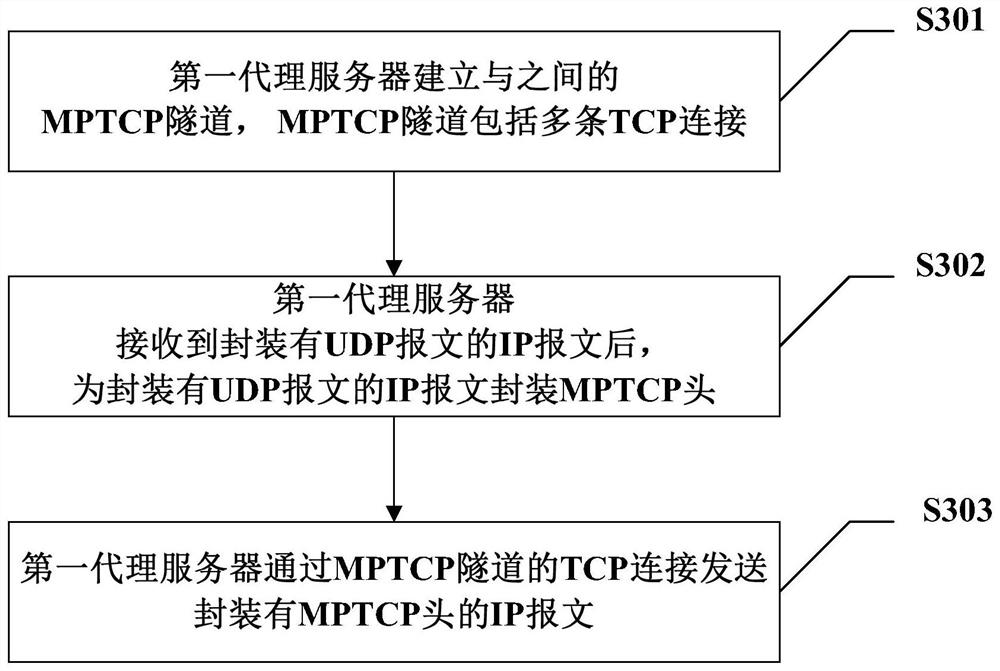

Method for transmitting messages, proxy server and computer readable storage medium

ActiveCN109120540ASolve technical problems with poor compatibilityData switching networksTransport control protocolComputer compatibility

A method for transmitting messages, a proxy server and a computer-readable storage medium are provided. The method includes the following steps: a first proxy server establishes a multi-path transportcontrol protocol MPTCP tunnel between the first proxy server and a second proxy server, wherein the MPTCP tunnel includes a plurality of transport control protocol TCP connections; after receiving anInternet protocol IP message encapsulated with a user datagram protocol UDP message, the first proxy server encapsulates an MPTCP header for the IP message encapsulated with a UDP message; and the first proxy server sends the IP message encapsulated with an MPTCP header through the TCP connections of the MPTCP tunnel. By adopting the embodiment of the invention, the technical problem of poor compatibility in the prior art can be solved, and a complete UDP message can be restored.

Owner:HUAWEI TECH CO LTD

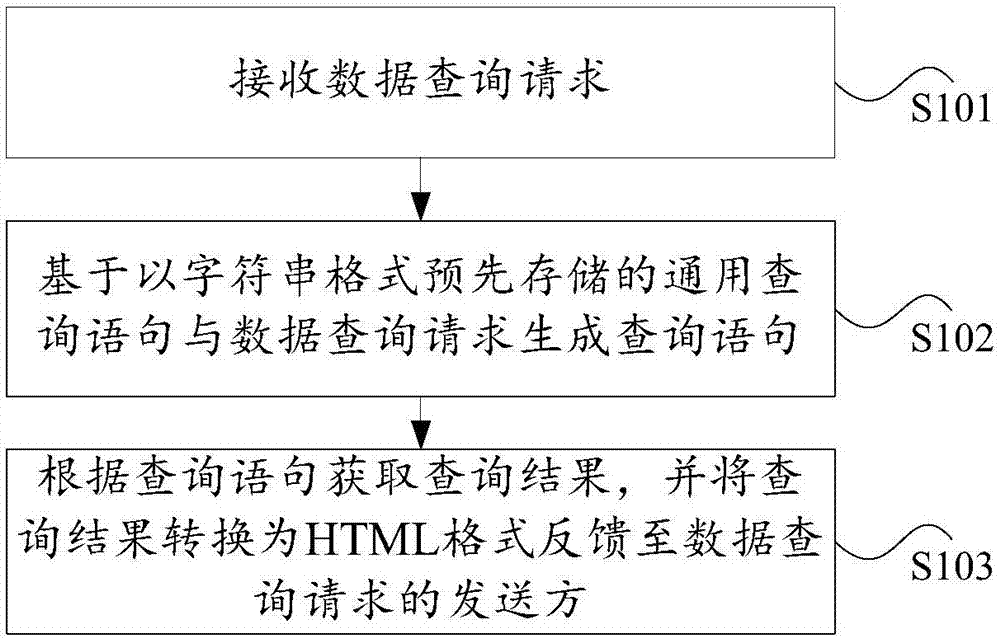

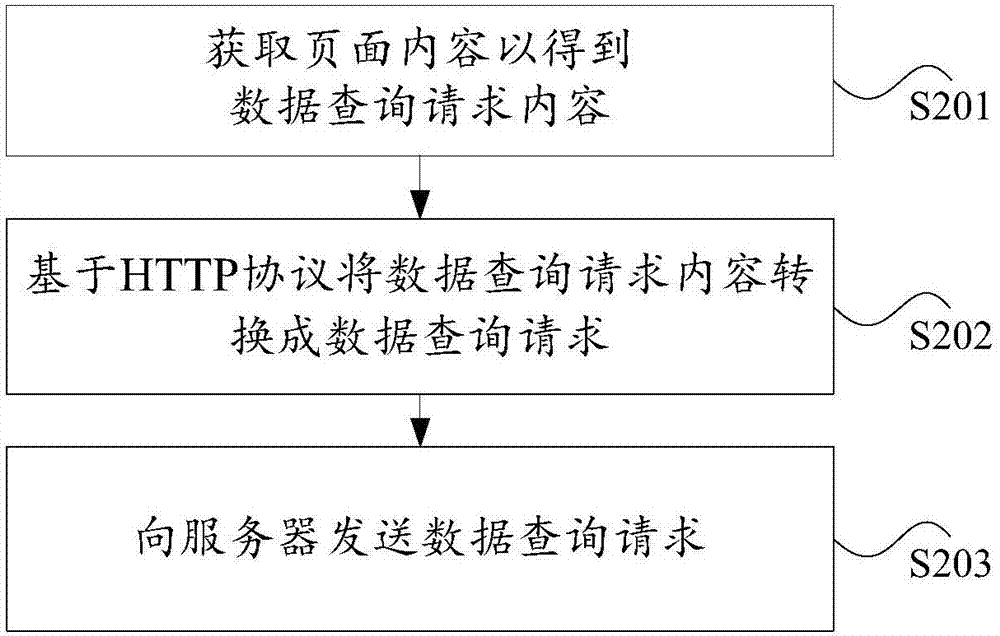

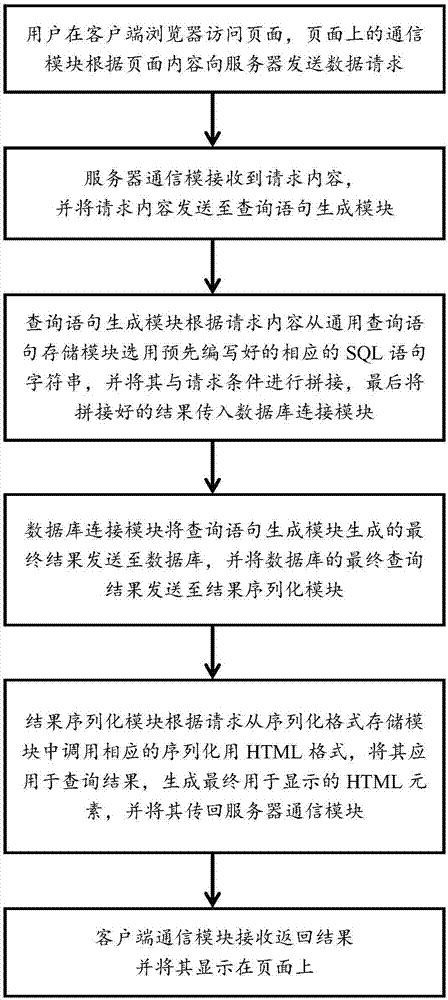

Page data query method and device

InactiveCN107423342ASolve technical problems with poor compatibilityPerfectly compatibleSpecial data processing applicationsData displayHyper text transport protocol

The invention discloses a page data query method and device. The method comprises the following steps that: receiving a data query request, wherein the data query request is generated on the basis of an HTTP (Hyper Text Transport Protocol) protocol according to page contents; on the basis of a general query statement pre-stored in a character string format and the data query request, generating a query statement; and according to the query statement, obtaining a query result, converting the query result into an HTML format, and feeding back the HTML format to a data query request sender. By use of the method, the technical problem in the relevant art that a method for inquiring server data displayed on the page is poor in browser compatibility is solved.

Owner:CAXA TECH

Viscosity modifier for concrete and preparation method thereof

The invention belongs to the technical field of concrete admixtures, and discloses a viscosity modifier for concrete and a preparation method of the viscosity modifier. The preparation method comprises the following steps: carrying out hydrolytic polycondensation on a vinyl silane coupling agent and a fluorosilane coupling agent in an isopropanol solvent at normal temperature to obtain a silane modified monomer; adding unsaturated carboxylic acid, unsaturated amide, an internal cross-linking agent and a peroxide initiator into water, uniformly stirring and dissolving, introducing nitrogen to remove oxygen, heating to 40-70 DEG C, dropwise adding a mixed solution containing a silane modified monomer and a reducing agent, carrying out a copolymerization reaction, cooling to room temperature after the reaction, and adding alkali for neutralization to obtain the viscosity modifier for concrete. The viscosity modifier disclosed by the invention can be used for improving the problems of bleeding and segregation caused by a polycarboxylic acid water reducing agent, has a remarkable tackifying effect and a peaceability improving effect, and has a certain effect of improving the early strength of concrete.

Owner:广东鼎基建材科技有限公司

Phosphorus II type anhydrous gypsum-based self-leveling mortar

The invention belongs to the technical field of building materials, and particularly relates to phosphorus II type anhydrous gypsum-based self-leveling mortar. The self-leveling mortar comprises water, cement, slag, an activating agent, phosphorus II type anhydrite and a water reducing agent, wherein the water reducing agent is a sulfonated melamine water reducing agent. The invention solves the technical problem that the compatibility of the existing water reducing agent and activating agent is poor when the phosphorus II type anhydrite is used for the self-leveling mortar.

Owner:重庆杰博思石膏有限公司

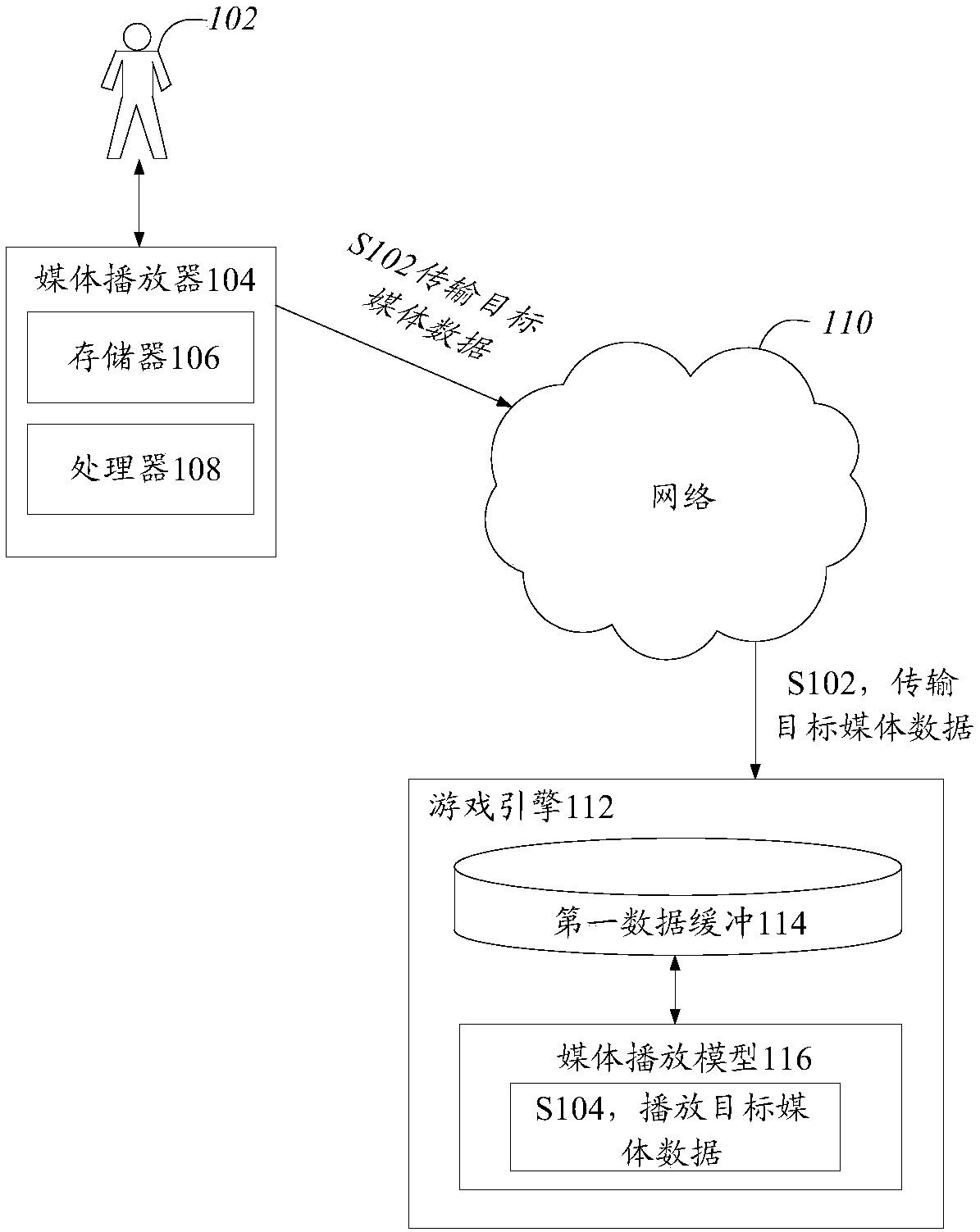

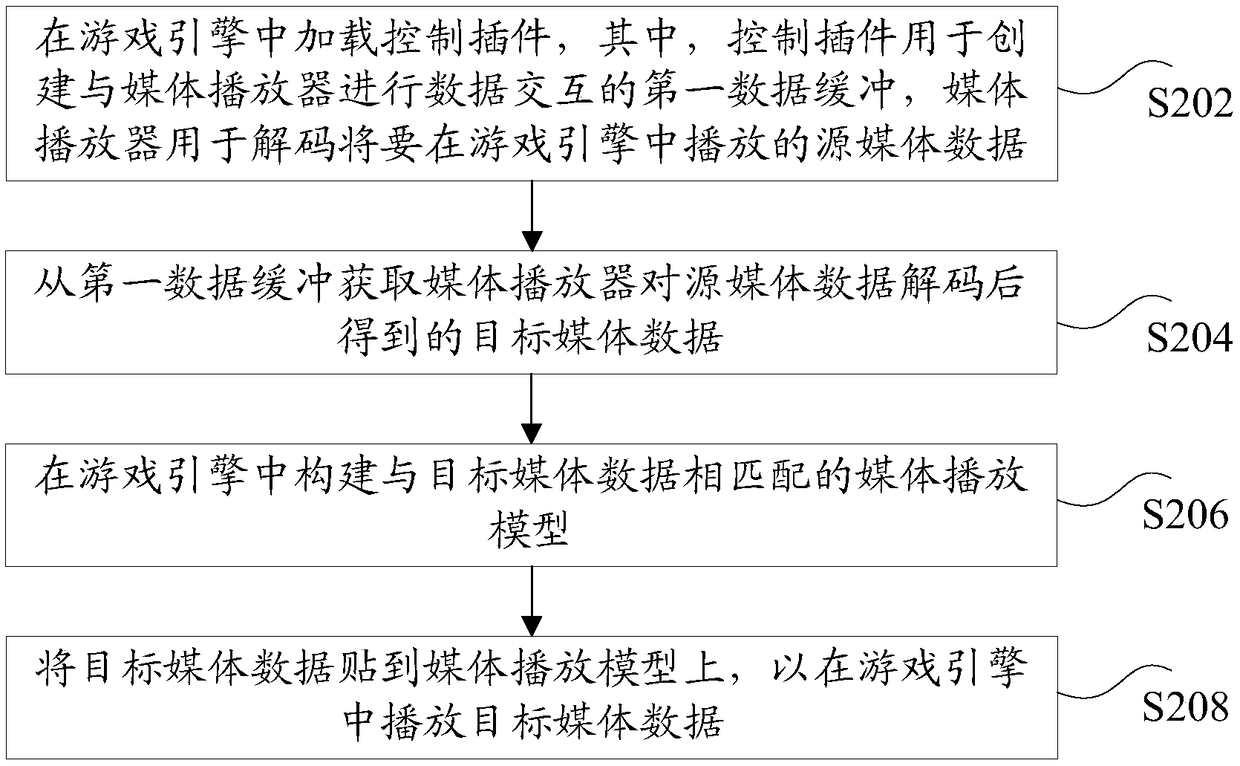

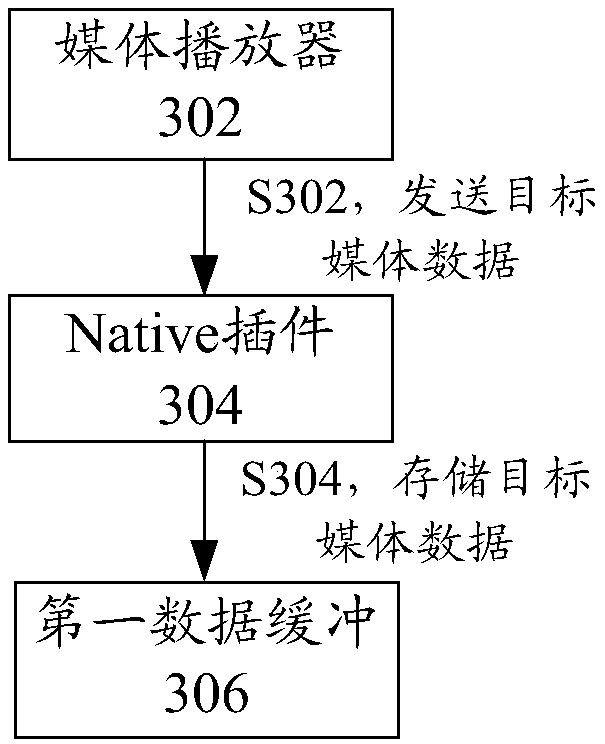

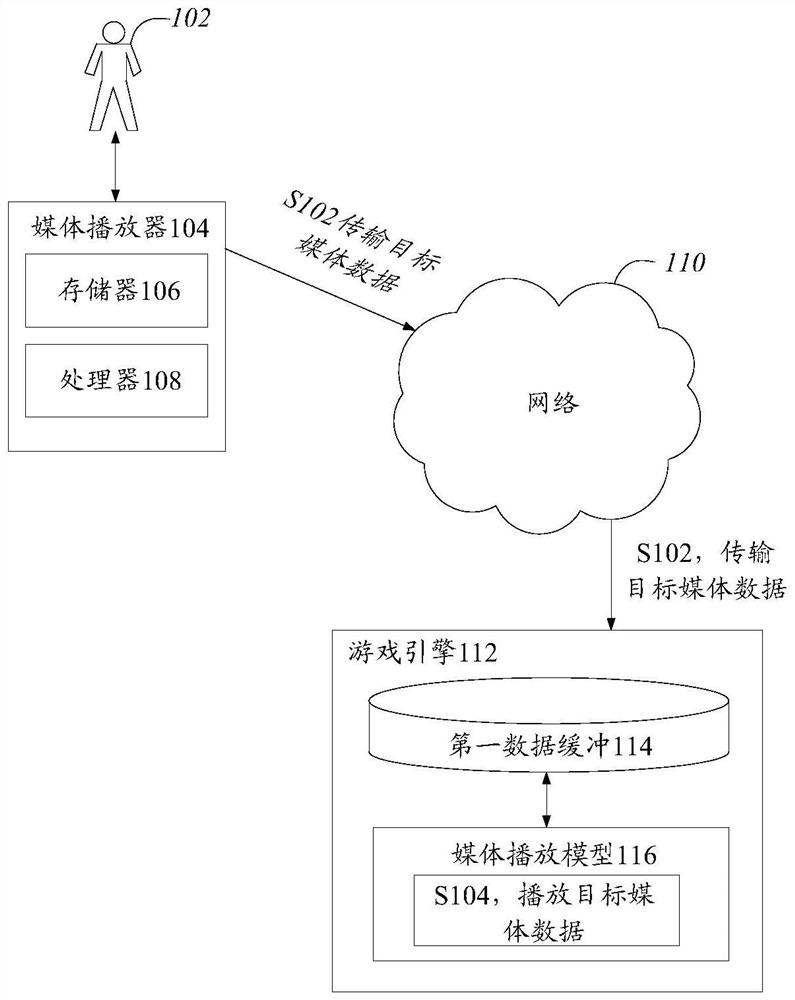

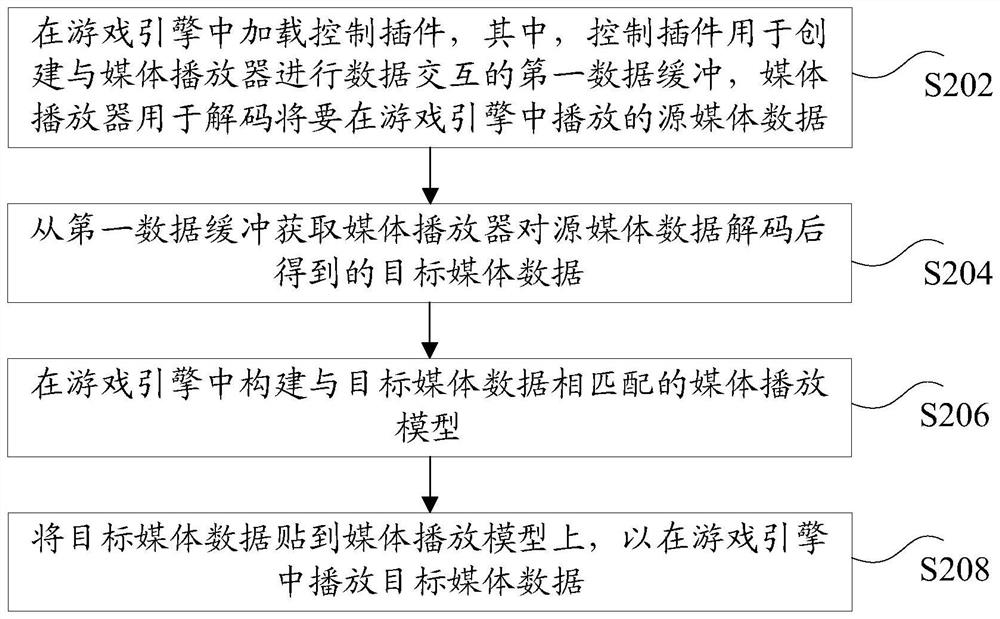

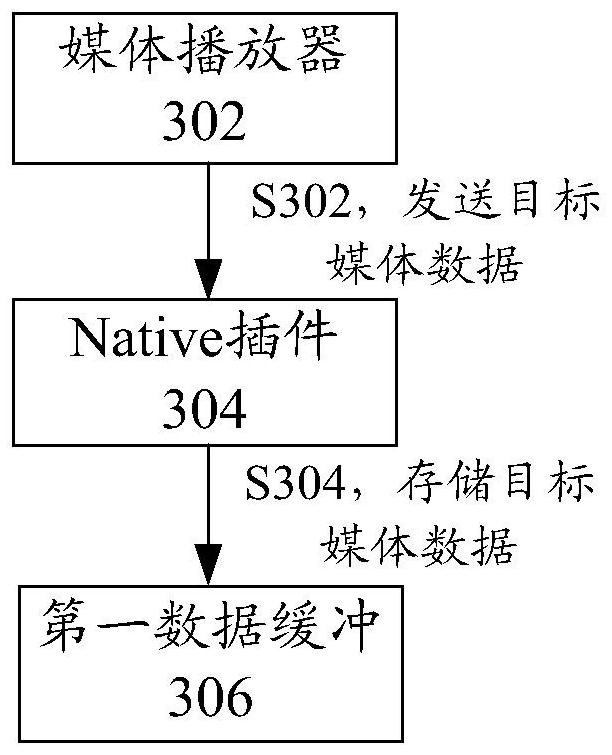

Data playing method and device, storage medium and electronic device

ActiveCN108786113ASolve technical problems with poor compatibilityVideo gamesSelective content distributionGame engine

The invention discloses a data playing method, a data playing device, a storage medium and an electronic device. The method comprises the following step: loading a control plug-in in a game engine, wherein the control plug-in is used for creating first data buffering performing data interaction with a media player, and the media player is used for decoding source media data to be played in the game engine; acquiring target media data obtained by decoding the source media data through the media player from the first data buffering; constructing a media play model matched with the target mediadata in the game engine; and attaching the target media data to the media play model, so that the target media data is played in the game engine. With the data playing method, the data playing device,the storage medium and the electronic device, the technical problem that the compatibility of the game engine is poor caused by the fact that the game engine is not compatible with different audio / video formats is solved.

Owner:TENCENT TECH CHENGDU

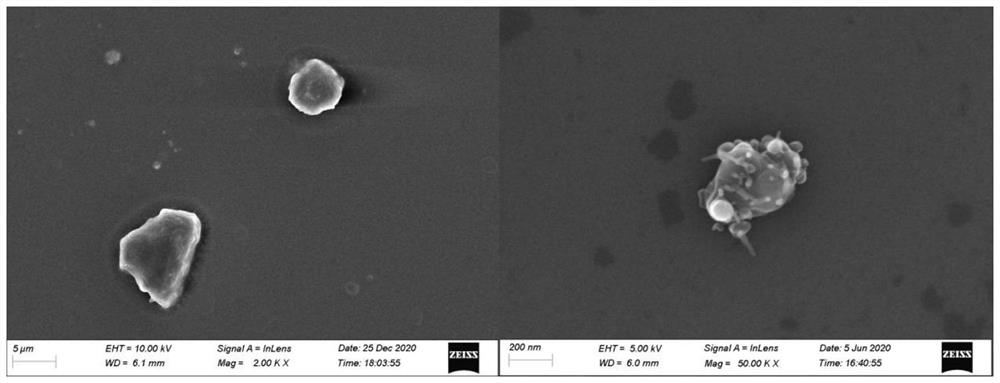

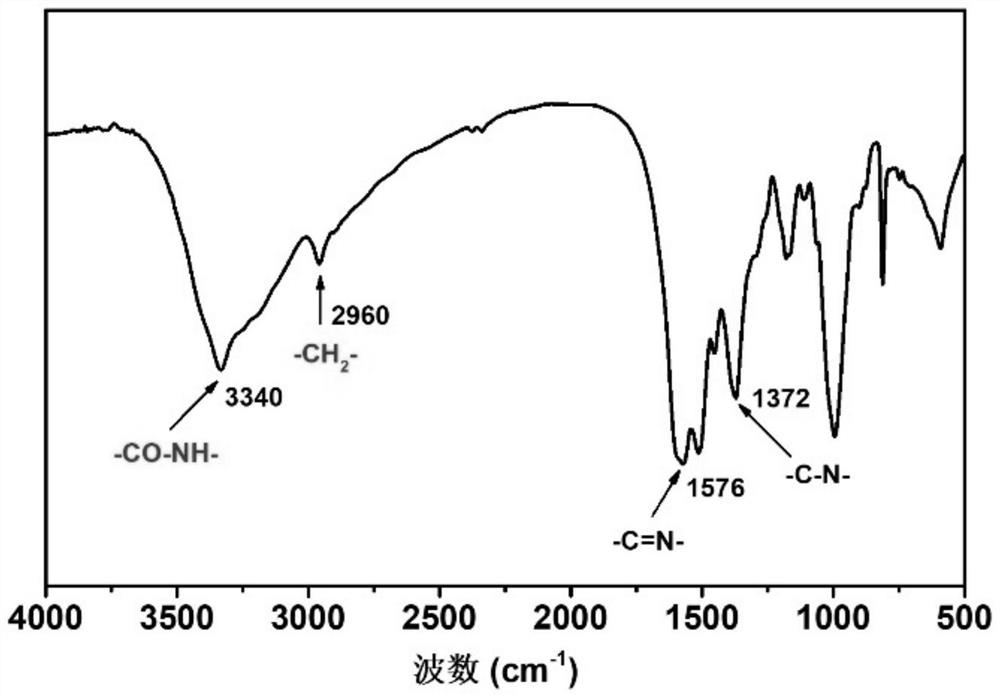

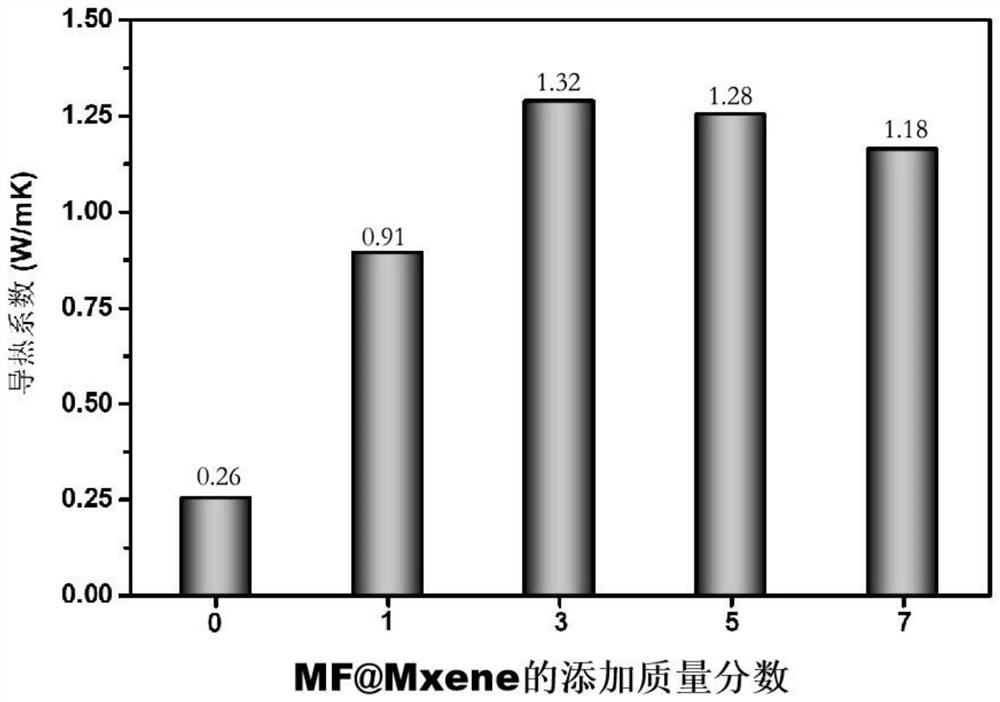

Preparation method and application of efficient heat-conducting UV-LED printing ink

PendingCN114163867AImprove dispersionAvoid reunionInksChemical industryPrepolymerIn situ polymerization

The invention provides a preparation method and application of efficient heat-conducting UV-LED printing ink. Firstly, a melamine-formaldehyde prepolymer is synthesized, then aluminum carbide is stripped through a lithium fluoride acid solution to prepare Mxene, finally, the melamine-formaldehyde prepolymer and the stripped Mxene are subjected to in-situ polymerization, melamine-formaldehyde modified Mxene is obtained, and the efficient heat-conducting UV-LED printing ink is obtained. Mxene is subjected to embedding treatment by adopting melamine-formaldehyde resin, so that the dispersity of Mxene is improved, the technical problem of poor compatibility of Mxene and an ink matrix is solved, and the efficient heat-conducting UV-LED ink is prepared by adopting the binder, the pigment and various auxiliaries as auxiliary materials, so that the efficient heat-conducting UV-LED ink is prepared. The UV-LED heat-conducting ink is prepared by adding the Mxene into the UV-LED heat-conducting ink, so that the agglomeration of the Mxene is effectively prevented, the heat conductivity of the heat-conducting ink is greatly improved, and the heat conductivity coefficient of an ink film in the plane direction after printing is up to 1.32 W / m.K.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

Interface generation method and device, storage medium and electronic equipment

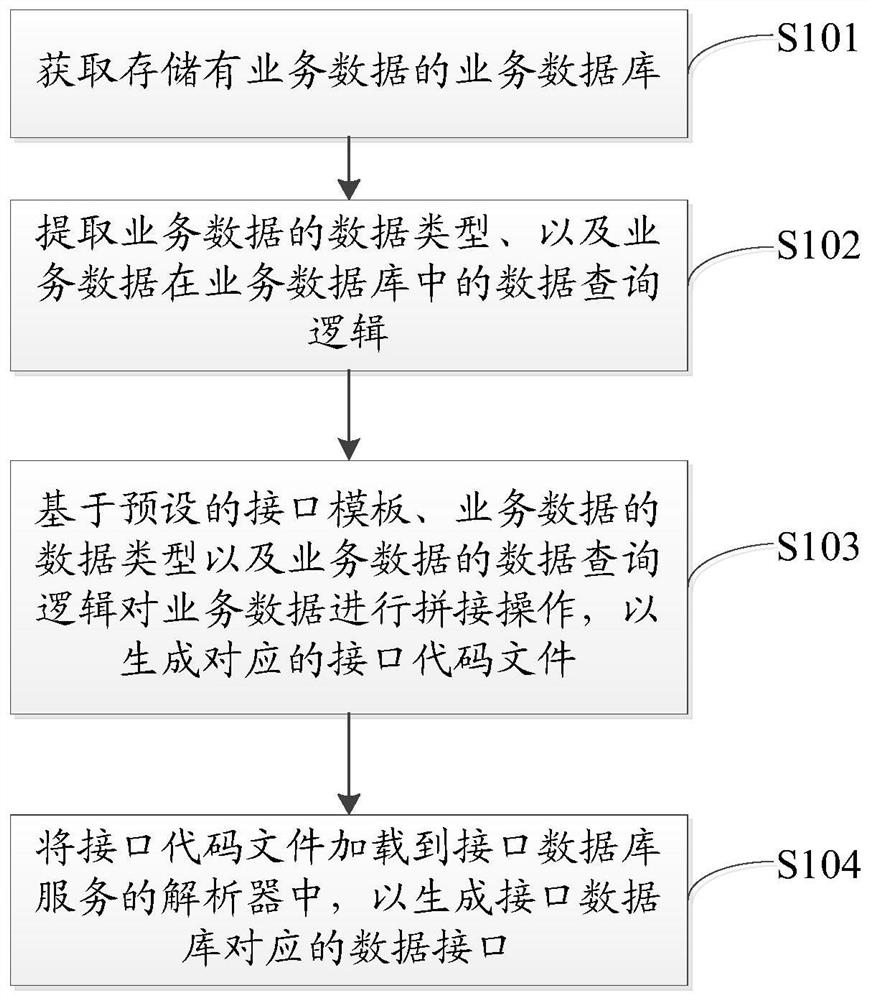

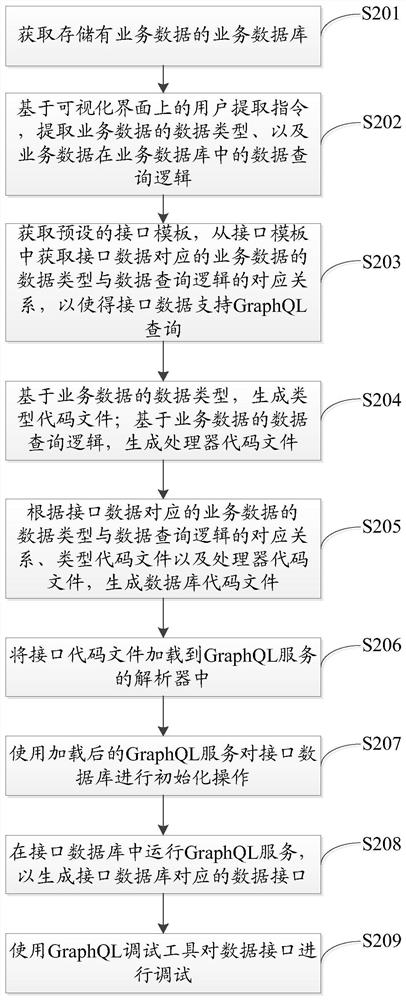

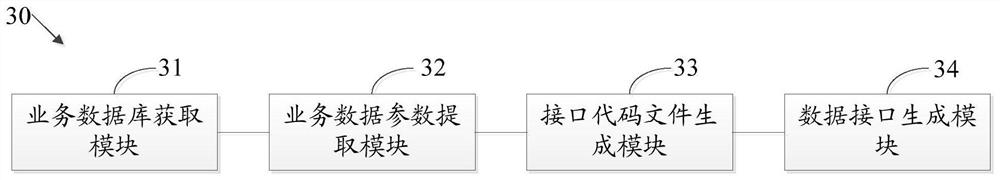

ActiveCN112256252AEliminate redundancyQuick buildProgram documentationIntelligent editorsData classEngineering

The invention provides an interface generation method. The interface generation method comprises the steps of obtaining a service database storing service data; extracting the data type of the servicedata and the data query logic of the service data in the service database; splicing the service data based on a preset interface template, the data type of the service data and the data query logic of the service data to generate a corresponding interface code file; and loading the interface code file into an analyzer of the interface database service to generate a data interface corresponding tothe interface database. The invention further provides an interface generation device, the service data is spliced based on the interface template, the corresponding interface code file is generated,and rapid generation and modification of the data interface can be achieved; and the generated data interface can be reused by other interface templates, and minimum data definition can be performedon the interface data through the interface templates, so that interface data redundancy is eliminated, and convenience is brought to test personnel to test the data interface.

Owner:TENCENT TECH (SHENZHEN) CO LTD

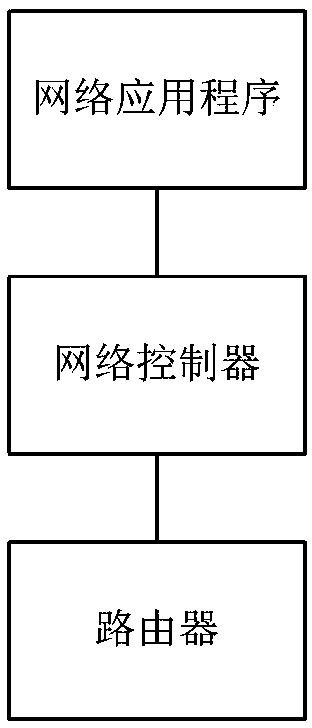

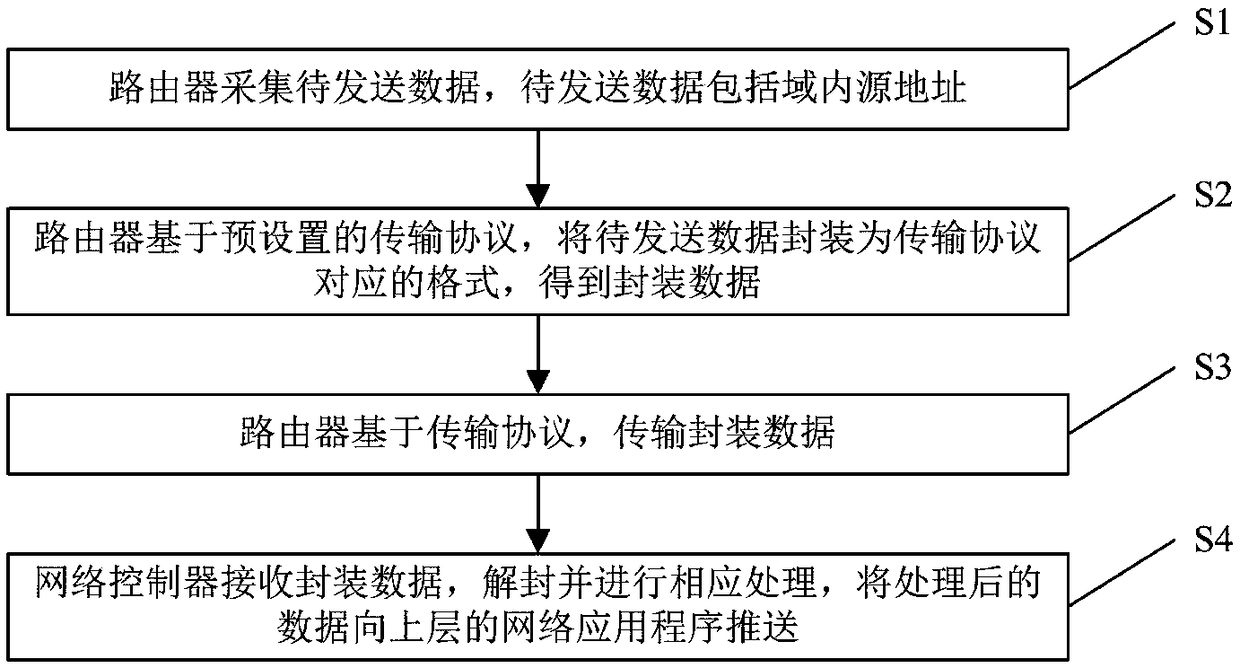

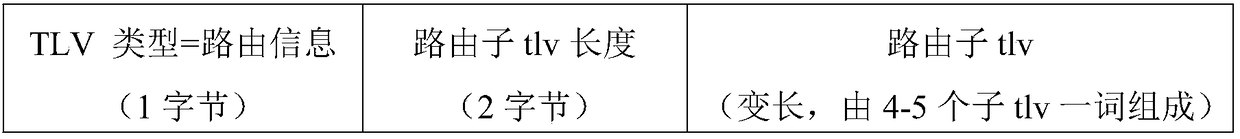

Method for verifying intra-domain source address of software-defined network

InactiveCN109150895ASolve technical problems with poor compatibilityAvoiding the False Positive ProblemData switching networksTransmission protocolValidation methods

The invention provides a method for verifying the intra-domain source address of a software-defined network, which relates to the technical field of software-defined network. A router collects data tobe sent, wherein the data to be sent includes an intra-domain source address; based on a preset transmission protocol, the router encapsulates the data to be sent into a format corresponding to the transmission protocol to obtain encapsulated data; the router transmits the encapsulated data based on the transmission protocol; a network controller receives the encapsulated data, de-encapsulates the data and processes the data accordingly, and pushes the processed data to an upper network application; and the upper network application verifies the intra-domain source address in the received data. The technical problem of poor compatibility of CPF (Calculating Path Forwarding) in the prior art is solved by transplanting CPF to a network environment incorporating the idea of a software defined network system structure.

Owner:TSINGHUA UNIV

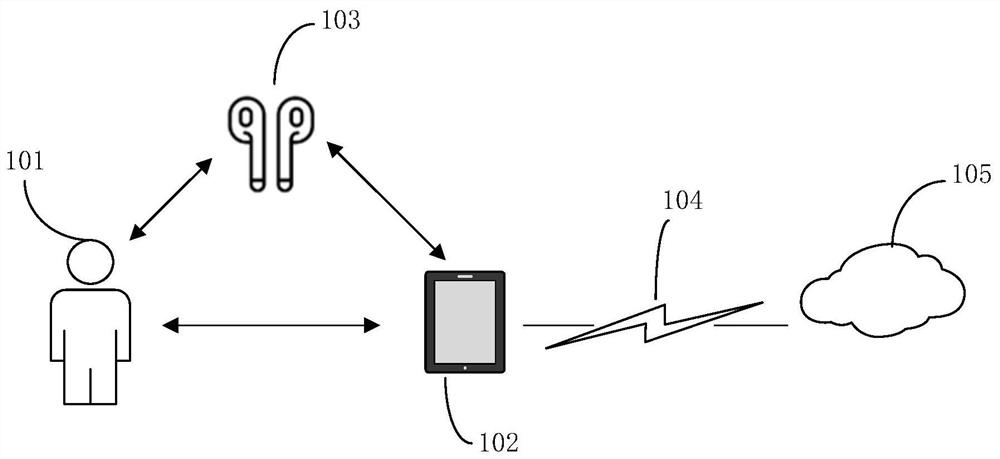

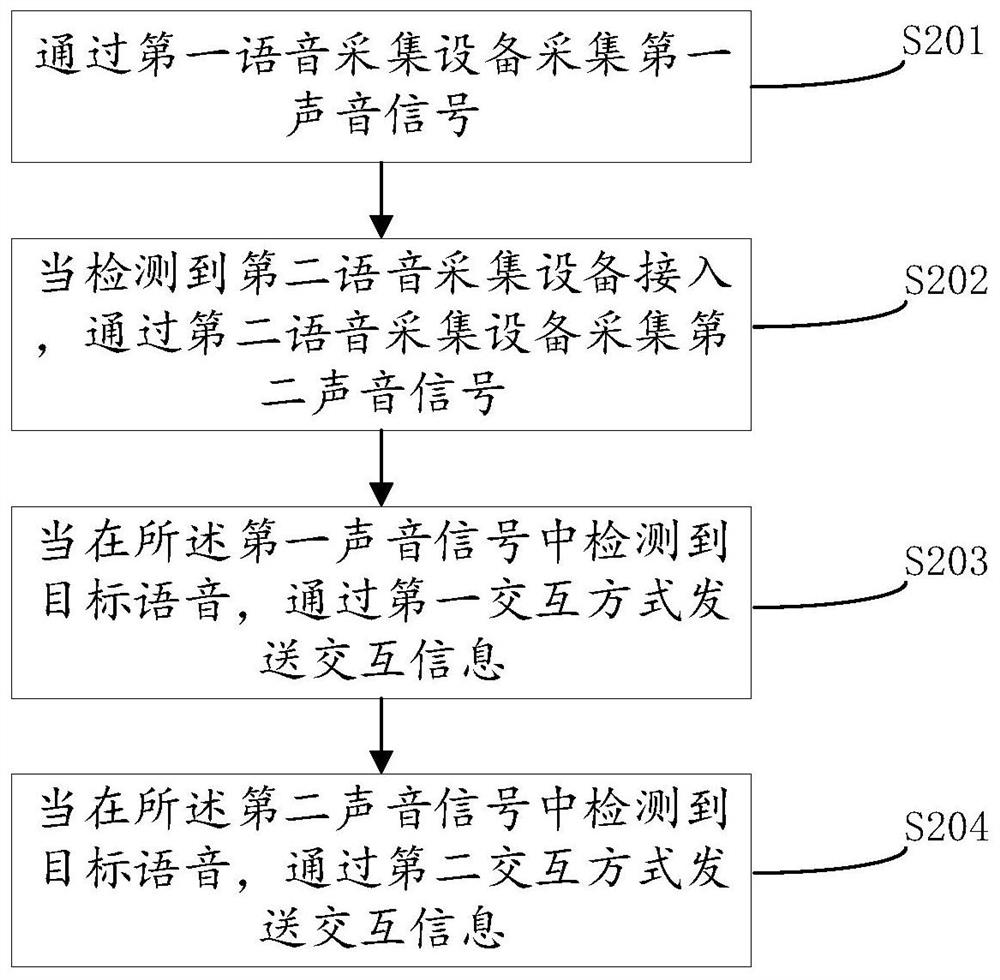

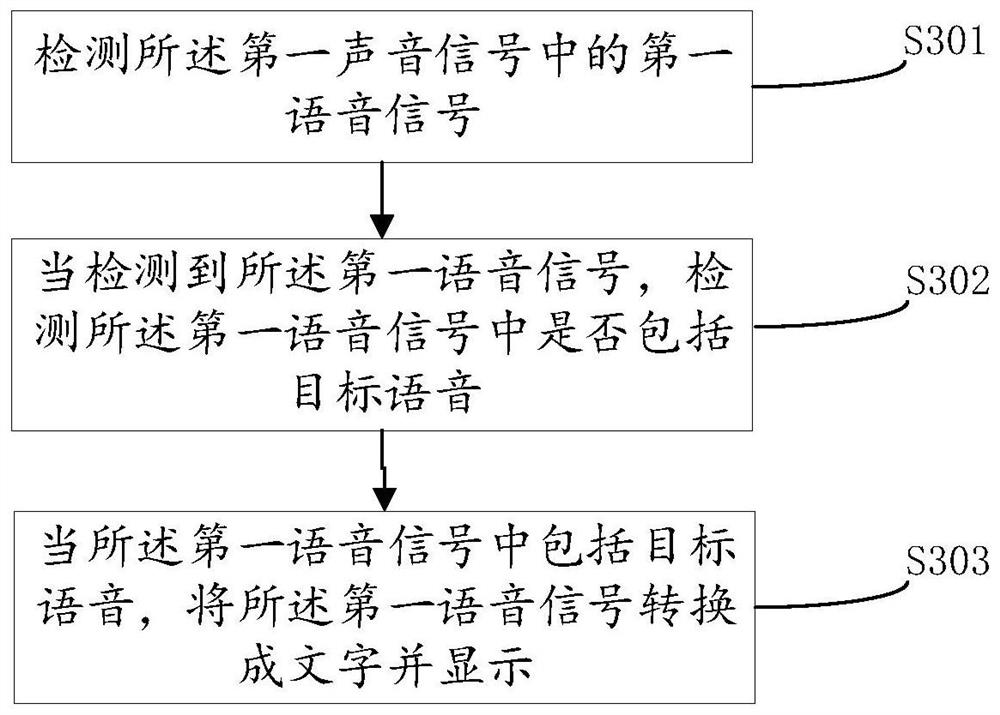

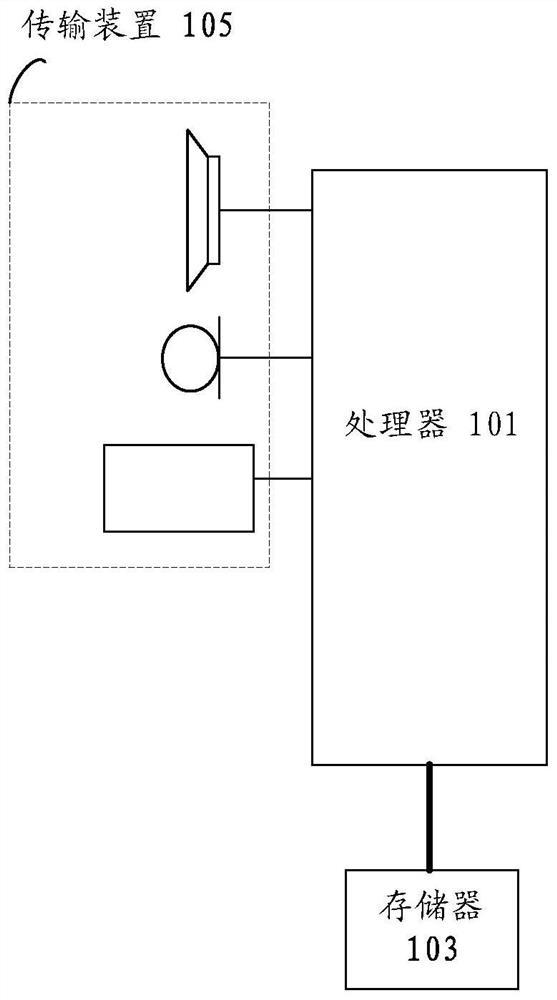

Voice interaction method and device, electronic equipment and computer readable storage medium

PendingCN112259076ASolve technical problems with poor compatibilitySpeech recognitionSound sourcesAcquisition apparatus

The embodiment of the invention discloses a voice interaction method and device, electronic equipment and a computer readable storage medium. The voice interaction method comprises the following steps: acquiring a first sound signal through first voice acquisition equipment; acquiring a second sound signal through second voice acquisition equipment when detecting that the second voice acquisitionequipment is accessed; when a target voice is detected in the first sound signal, sending interaction information in a first interaction mode; and when a target voice is detected in the second sound signal, sending interaction information in a second interaction mode. According to the method, the voice source is switched to different voice acquisition devices, and the voice is directly acquired from different sound sources, so that the technical problem of poor matching when voice interaction is performed through the voice acquisition devices in the prior art is solved.

Owner:SOUNDAI TECH CO LTD

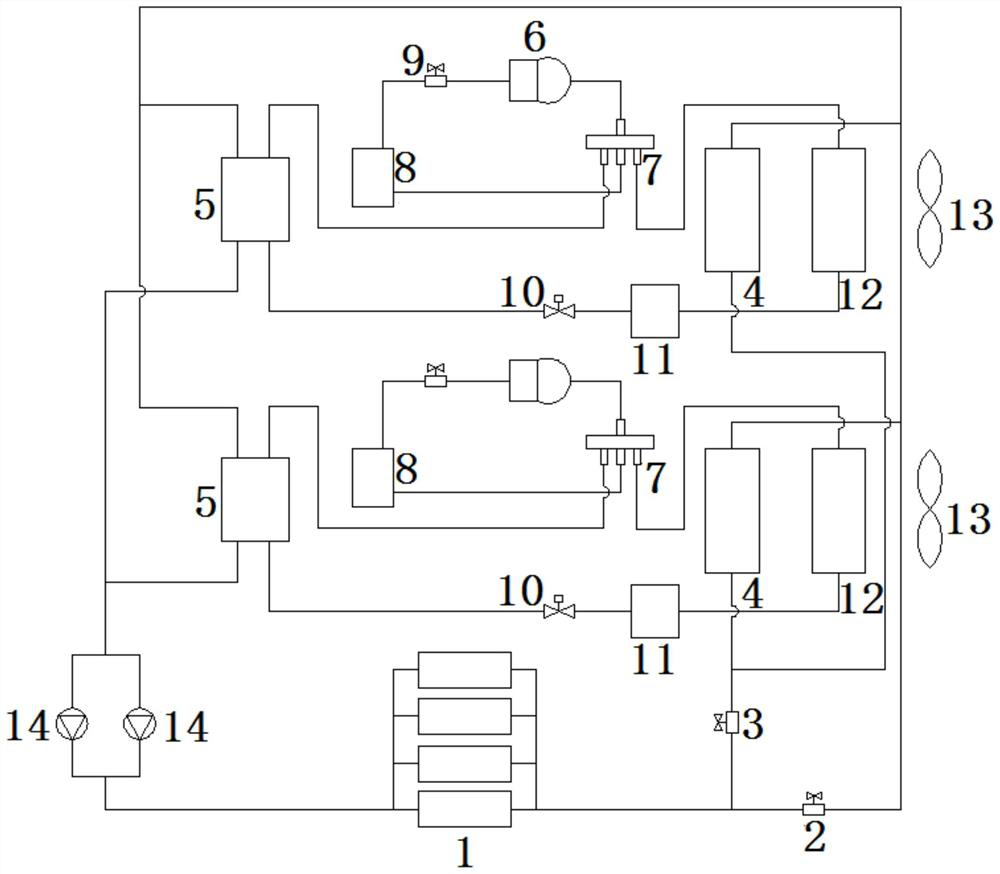

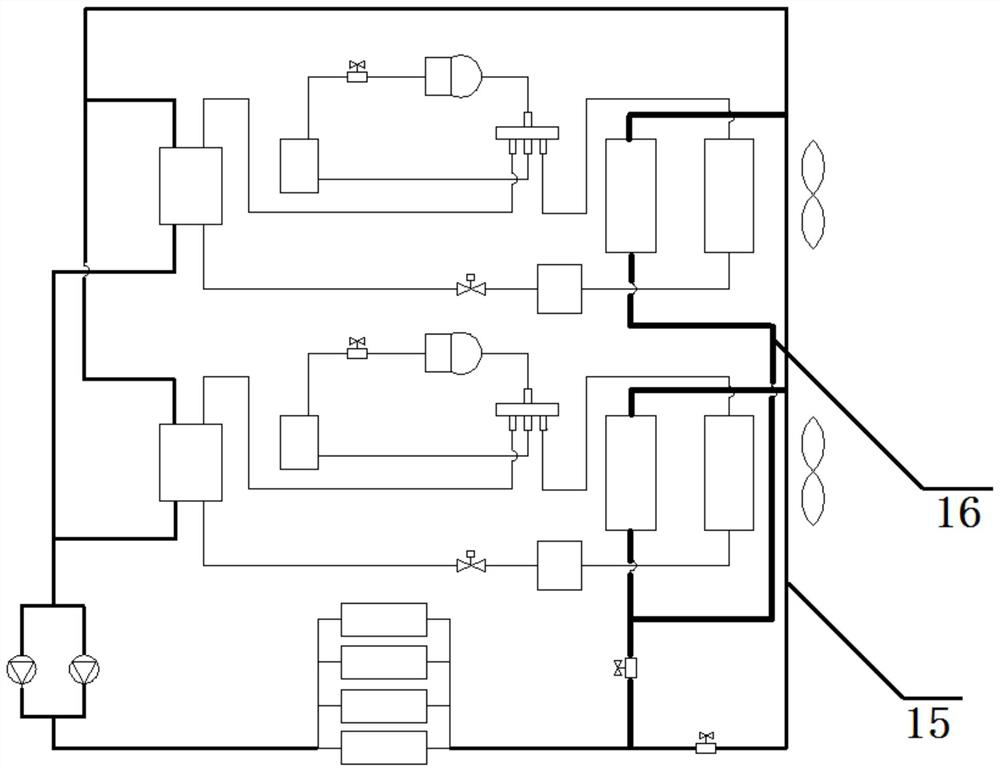

Immersed liquid cooling system and control method

PendingCN114520383AMeet cooling capacitySolve technical problems with poor compatibilitySecondary cellsEnergy storageThermodynamicsElectrical battery

The invention discloses an immersed liquid cooling system and a control method, which are used for solving the technical problem of poor compatibility caused by the fact that an existing battery liquid cooling system cannot be adjusted according to the refrigerating capacity required by a battery. A heat exchange fluid supply device, a refrigerating and heating device and a circulating pump are connected in series through a first conveying pipeline, the first conveying pipeline is connected with a first electromagnetic valve, and the first electromagnetic valve is located between the heat exchange fluid supply device and the refrigerating and heating device; an inlet of the second conveying pipeline is connected with an outlet of the heat exchange fluid supply device, an outlet of the second conveying pipeline is connected with the first conveying pipeline, the outlet of the second conveying pipeline is located between the first electromagnetic valve and the refrigerating and heating device, and the natural cooling heat exchange device is connected to the second conveying pipeline. A second electromagnetic valve is connected to the second conveying pipeline and located between the natural cooling heat exchange device and the heat exchange fluid supply device.

Owner:GUANGDONG HIWAVE TECH

High-temperature-resistant and friction-resistant coating for automobiles and preparation method thereof

InactiveCN110951355ASolve technical problems with poor compatibilityGood compatibilityFireproof paintsEpoxy resin coatingsFirming agentEther

The invention discloses a high-temperature-resistant and friction-resistant coating for automobiles. The high-temperature-resistant and friction-resistant coating is prepared from the following components in parts by weight: 80-100 parts of bisphenol A epoxy resin, 30-50 parts of acetone, 50-60 parts of a dicyandiamide curing agent and 60-90 parts of a high-temperature-resistant and friction-resistant filler prepared by taking polytetrafluoroethylene (PTEE) and polyether-ether-ketone (PEEK) as raw materials. The invention also discloses a preparation method of the high-temperature-resistant friction-resistant coating for automobiles, which comprises the following steps: preparing a high-temperature-resistant friction-resistant filler component, adding a part of the filler component into areaction kettle to react, and adding a curing agent into the reaction kettle to react, thereby obtaining the high-temperature-resistant and friction-resistant coating. According to the invention, through synchronous improvement of the formula and the process, the technical problem of poor compatibility among components in the use process of paint for automobile splines at present is solved, and the material strength is improved.

Owner:清远威凛材料科技有限公司

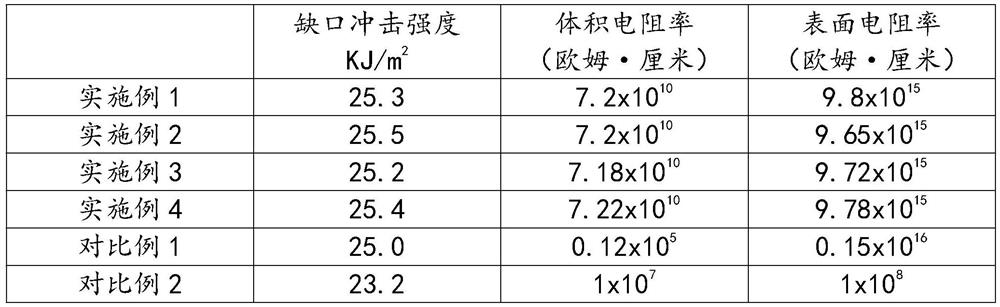

Antistatic plastic storage battery shell and production method thereof

InactiveCN112679872AImprove antistatic performanceSolve technical problems with poor compatibilityElastomerPolymer science

The invention discloses an antistatic plastic storage battery shell and a production method thereof. The antistatic plastic storage battery shell is prepared from the following raw materials in parts by weight: 10 to 15 parts of an antistatic filler, 55 to 75 parts of matrix resin, 5 to 10 parts of carbon black, 5 to 10 parts of a butylbenzene thermoplastic elastomer, 0.1 to 0.5 part of an antioxidant 1010 and 1 to 1.5 parts of zinc stearate. The preparation method comprises the following steps: step 1, adding the matrix resin and the antistatic filler into an internal mixer for internal mixing to prepare a composite material; and adding the composite material, the carbon black, the styrene-butadiene thermoplastic elastomer, the antioxidant 1010 and the zinc stearate into a mixing kettle, uniformly stirring, adding into a double-screw extruder, and extruding to obtain an antistatic plastic storage battery shell. One end of the product C contains an aliphatic hydrocarbon structure, the product C can be well compatible with a polymer matrix, the technical problem of poor compatibility of the antistatic agent and the polymer matrix is solved, the other end of the product C contains a large amount of hydroxyl, the product C can adsorb surrounding water molecules as a hydrophilic group to form a conductive layer, and the antistatic performance is improved.

Owner:安徽强旭塑业科技有限公司

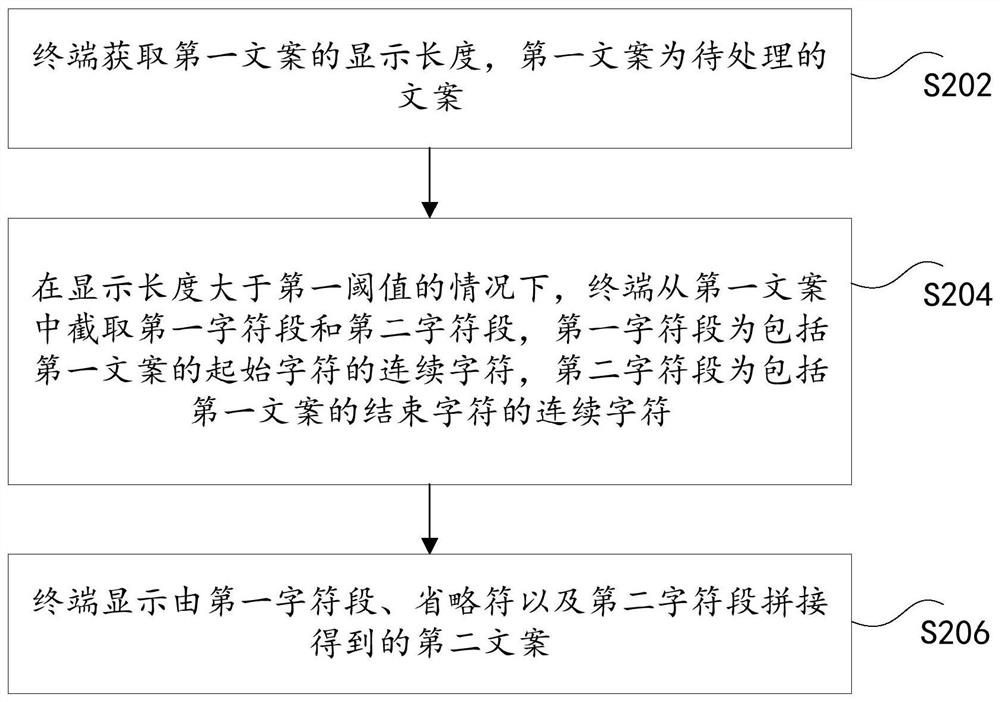

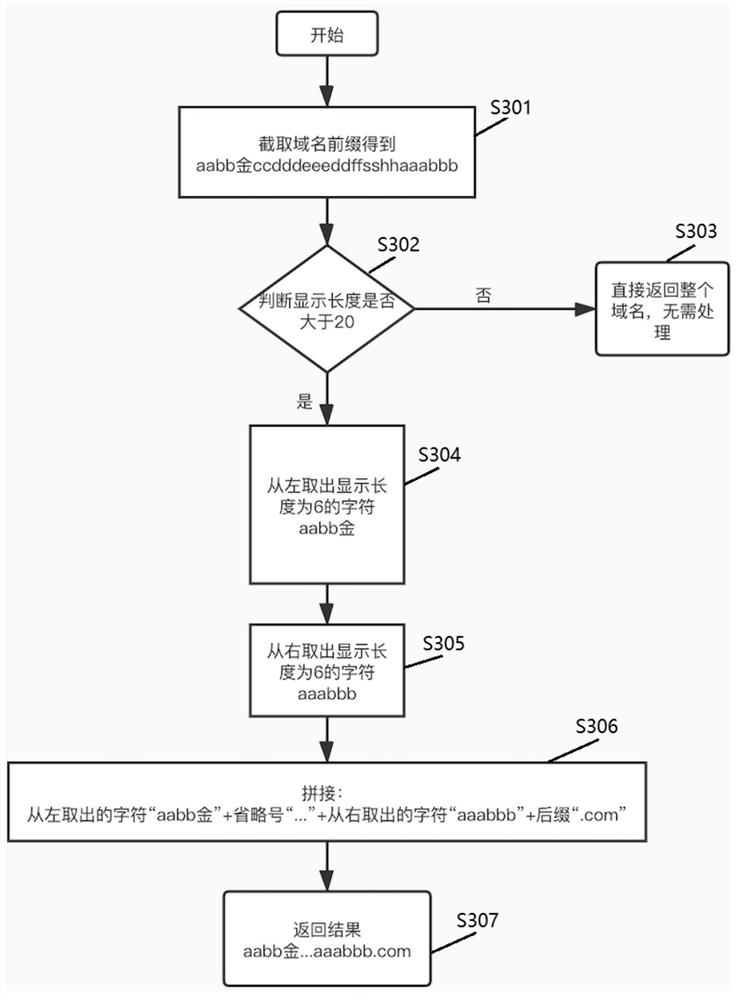

Cboth display method and device, storage medium and electronic device

PendingCN112861045ASolve technical problems with poor compatibilityImprove compatibilityNatural language data processingWebsite content managementSoftware engineeringMechanical engineering

The invention discloses a copywriting display method and device, a storage medium and an electronic device. The method comprises the steps that the display length of a first copywriting is obtained, and the first copywriting is a copywriting to be processed; when the display length is larger than a first threshold value, a first character field and a second character field are intercepted from the first copywriting, the first character field is a continuous character comprising a starting character of the first copywriting, and the second character field is a continuous character comprising an ending character of the first copywriting; and displaying a second copywriting obtained by splicing the first character field, the provincial character and the second character field. The technical problem of poor compatibility of a text omission scheme in related technologies is solved.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD

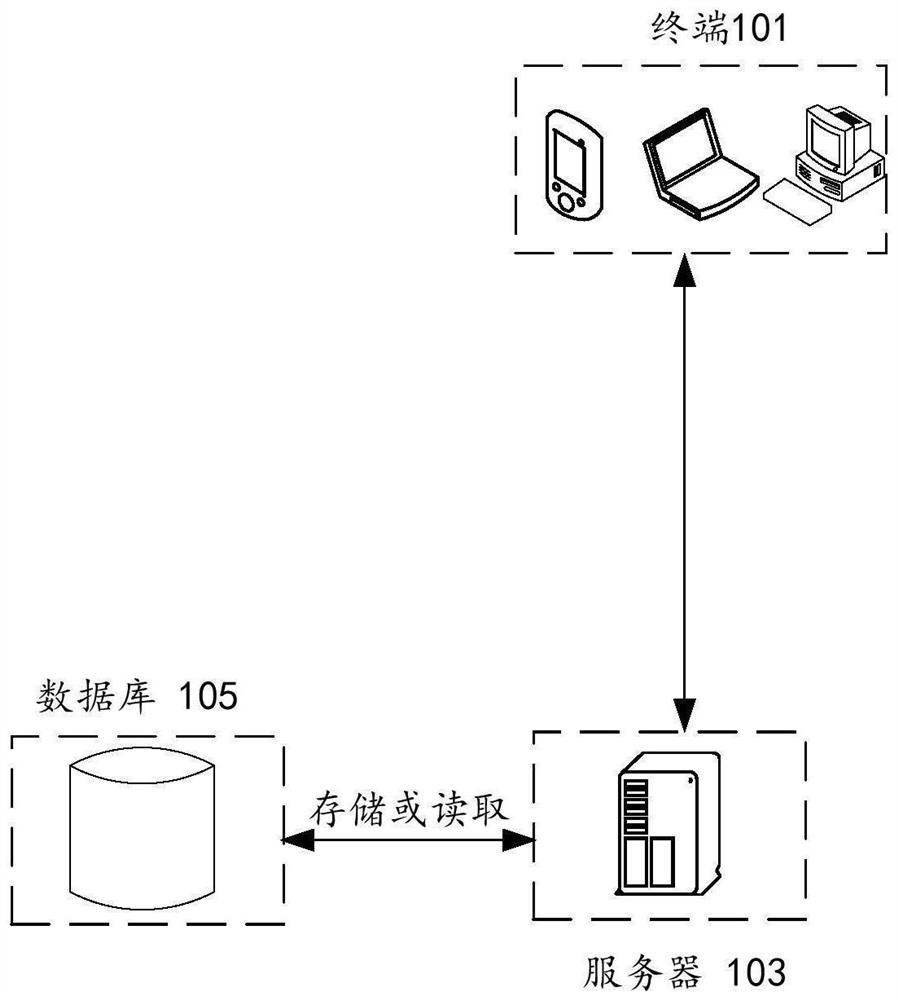

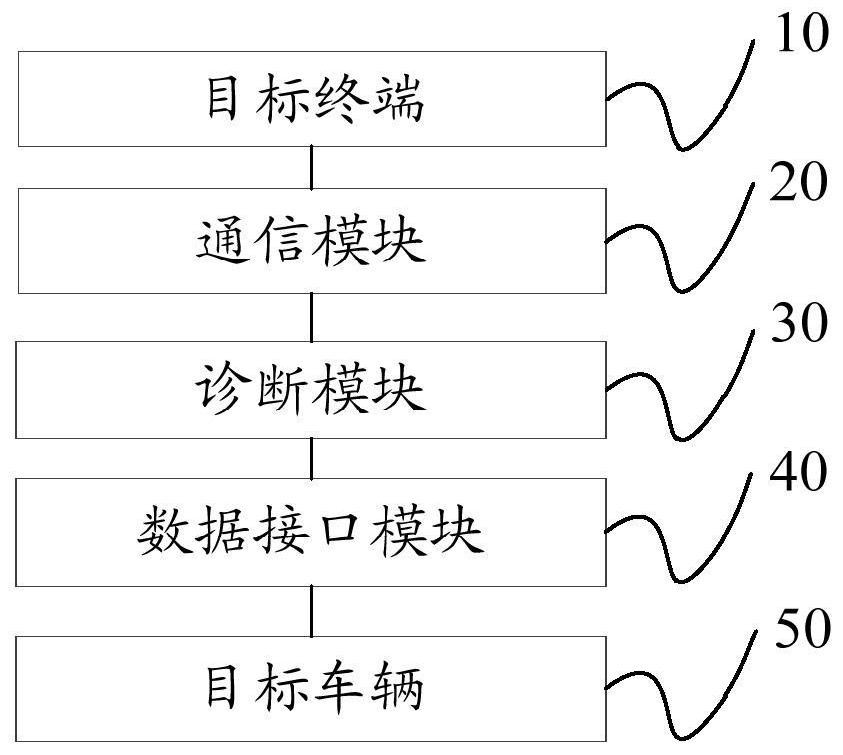

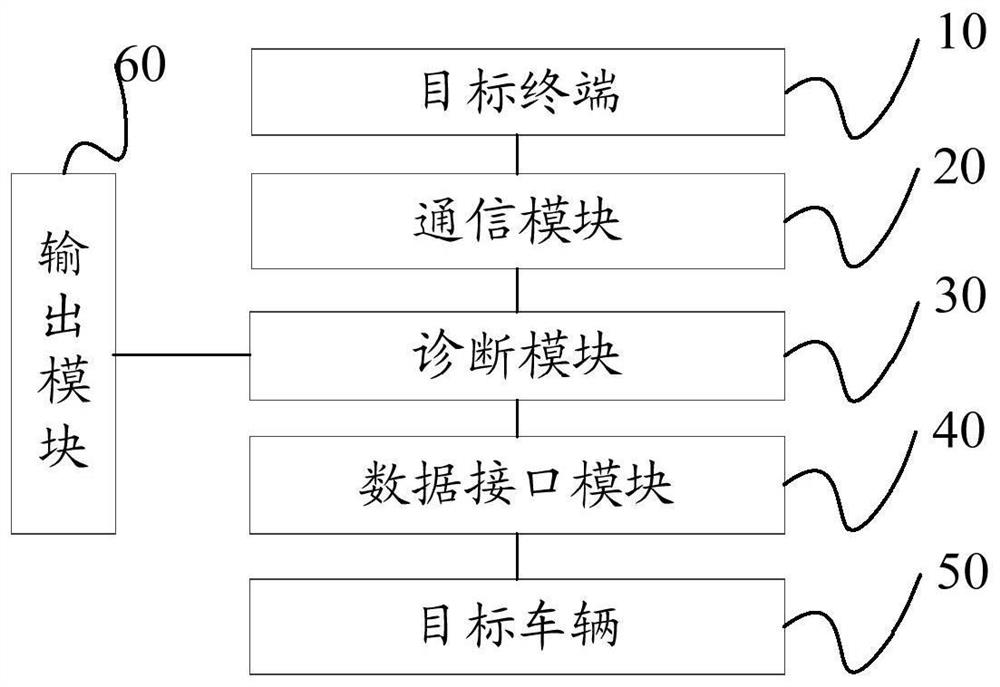

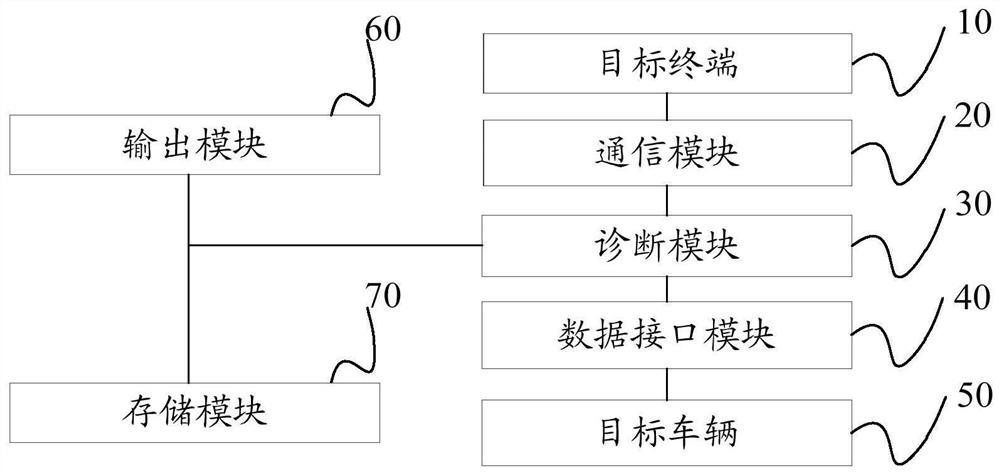

Vehicle communication interface and control method of vehicle communication

PendingCN114115173ASolve technical problems with poor compatibilityProgramme controlElectric testing/monitoringCommunication interfaceCommunication unit

The invention discloses a vehicle communication interface, which comprises a communication module used for determining a selected communication unit corresponding to a selection operation from an online communication unit and a wireless communication unit after the selection operation is received; the terminal is connected with a target terminal through the selected communication unit; receiving an acquisition instruction sent by the target terminal by using the selected communication unit; the diagnosis module is used for acquiring vehicle state information from the target vehicle by utilizing the data interface module based on the acquisition instruction; and the communication module is used for converting the vehicle state information into a sending signal by utilizing the selected communication unit and sending the sending signal to a target terminal. The invention further discloses a vehicle communication control method. According to the vehicle communication interface, wired or wireless communication with the target terminal can be carried out, even if the target terminal is not provided with a Bluetooth module, communication connection with the target terminal can still be achieved, and the compatibility of the vehicle communication interface is good.

Owner:深圳市天盛德隆科技有限公司

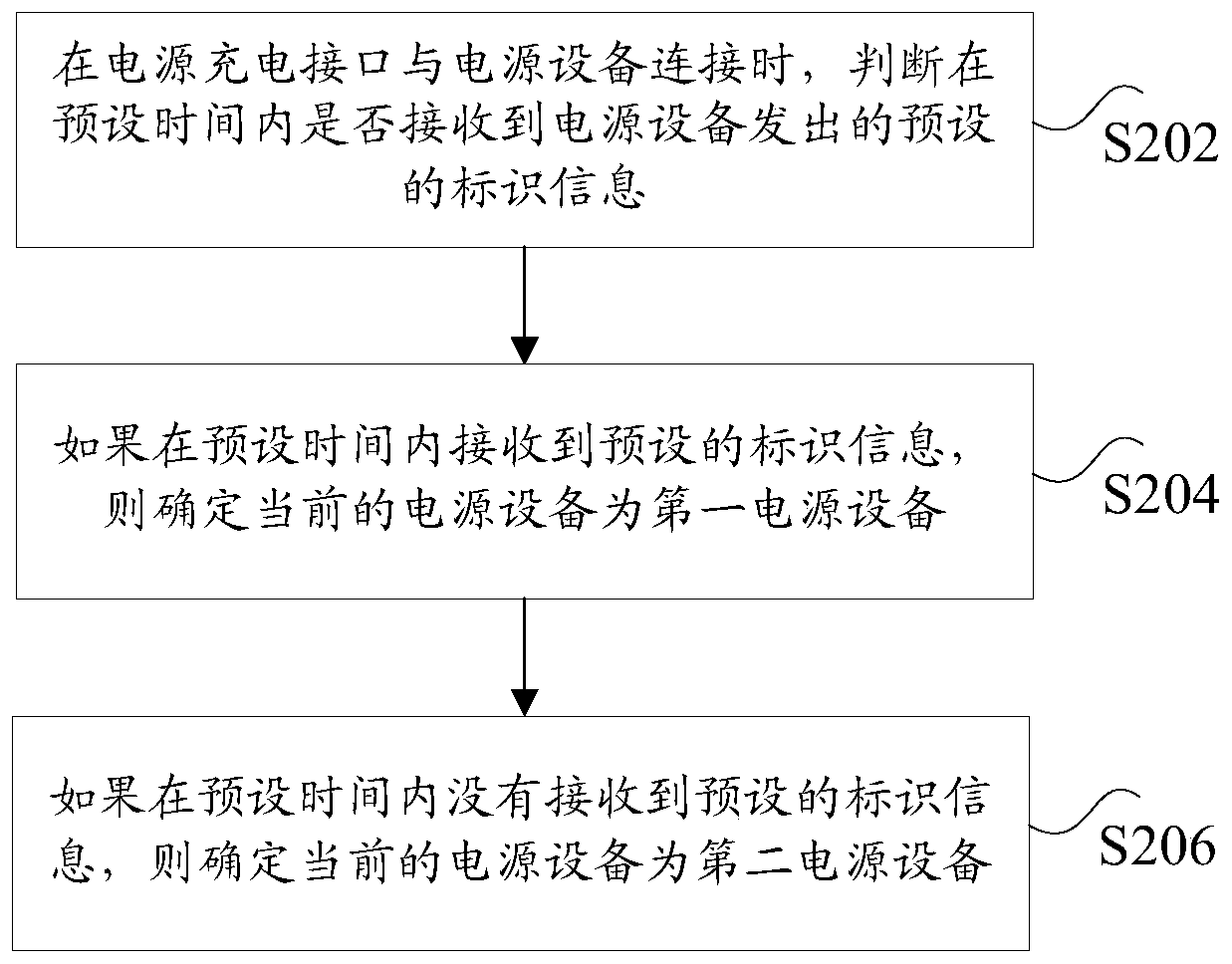

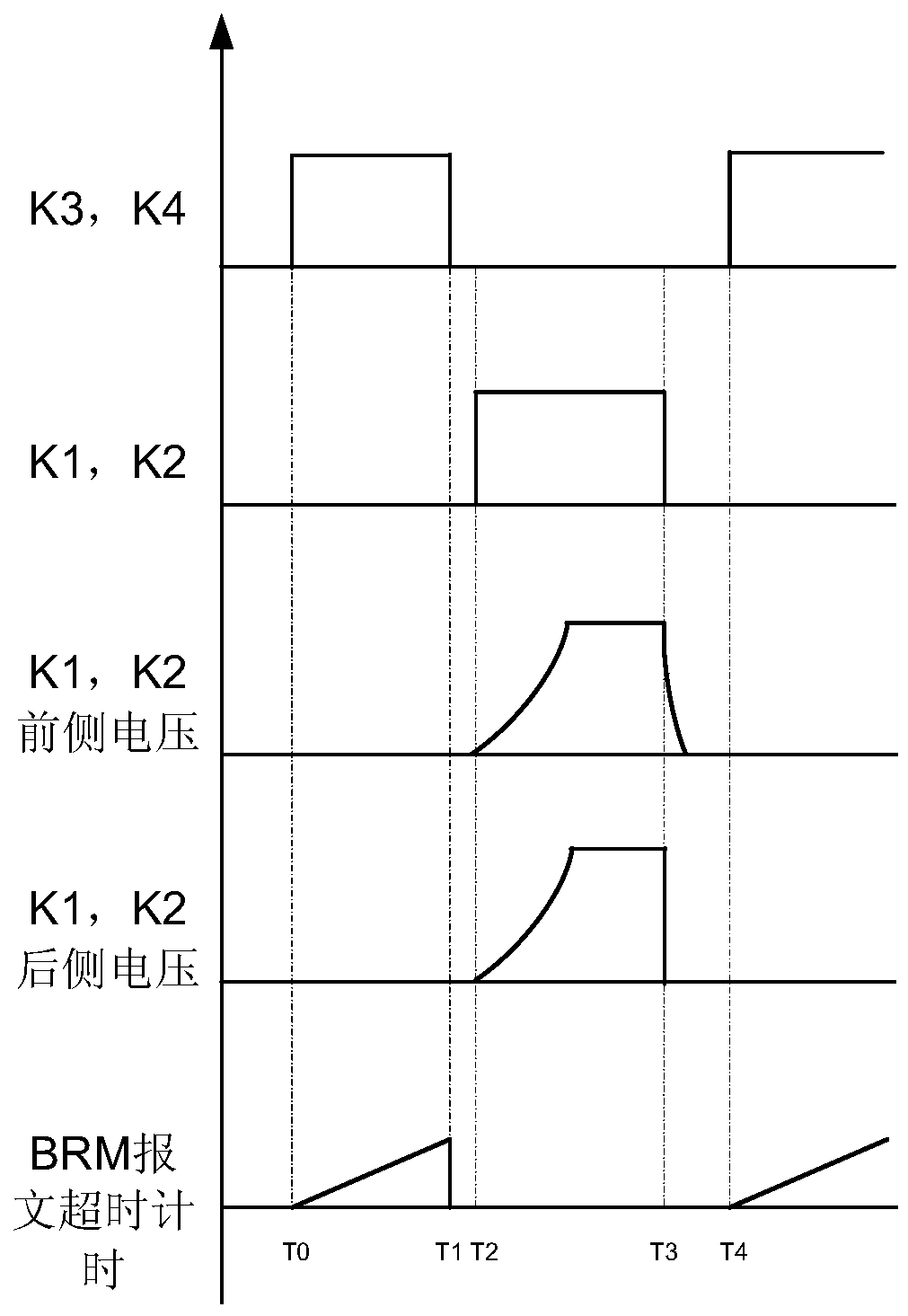

Charging method and device for DC charging equipment

ActiveCN106740196BAccurately determineSolve technical problems with poor compatibilityCharging stationsElectric vehicle charging technologyProcess engineeringDirect current

The invention discloses a charging method and device for direct current charging equipment, wherein the method comprises the following steps that when a power supply charging interface is connected with power supply equipment, whether the preset mark information sent by the power supply equipment can be received in the preset time or not is judged, wherein the preset mark information is the mark information sent on the basis of a preset charging protocol; if the preset mark information is received in the preset time, the current power supply equipment is determined to the first power supply equipment; if the preset mark information is not received in the preset time, the current power supply equipment is determined to be second power supply equipment. The charging method and device provided by the invention solve the technical problem of poor compatibility due to the direct current charging equipment in the prior art.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

Method for transmitting message, proxy server and computer-readable storage medium

ActiveCN109120540BSolve technical problems with poor compatibilityData switching networksData packEngineering

A method for transmitting messages, a proxy server and a computer-readable storage medium, the method comprising: the first proxy server establishes a multi-path transmission control protocol MPTCP tunnel with the second proxy server, and the MPTCP tunnel includes a plurality of Transmission Control Protocol TCP connection; after the first proxy server receives the Internet Association IP message that encapsulates the User Datagram Protocol UDP message, it encapsulates the MPTCP header for the IP message that encapsulates the UDP message; the first proxy server passes The TCP connection of the MPTCP tunnel sends an IP message encapsulated with an MPTCP header. After adopting the embodiment of the present invention, the technical problem of poor compatibility in the prior art can be solved, so that the complete UDP message can be restored.

Owner:HUAWEI TECH CO LTD

A kind of skin resource processing method and electronic device

ActiveCN104461615BSolve technical problems with poor compatibilityImprove compatibility2D-image generationSoftware deploymentComputer scienceElectronic equipment

The invention discloses a skin resource processing method which is applied in electronic equipment. The method comprises the steps of obtaining a current skin resource of an application program; judging whether the current skin resource contains a first image resource or not, wherein the first image resource is needed when a first interface element of the application program is drawn, the application program comprises a plurality of interface elements, and the first interface element is any one of the interface elements; when the current skin resource does not contain the first image resource, obtaining a built-in skin resource, and extracting the first image resource from the built-in skin resource; drawing the first interface element on the basis of the first image resource. The invention further discloses the electronic equipment.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

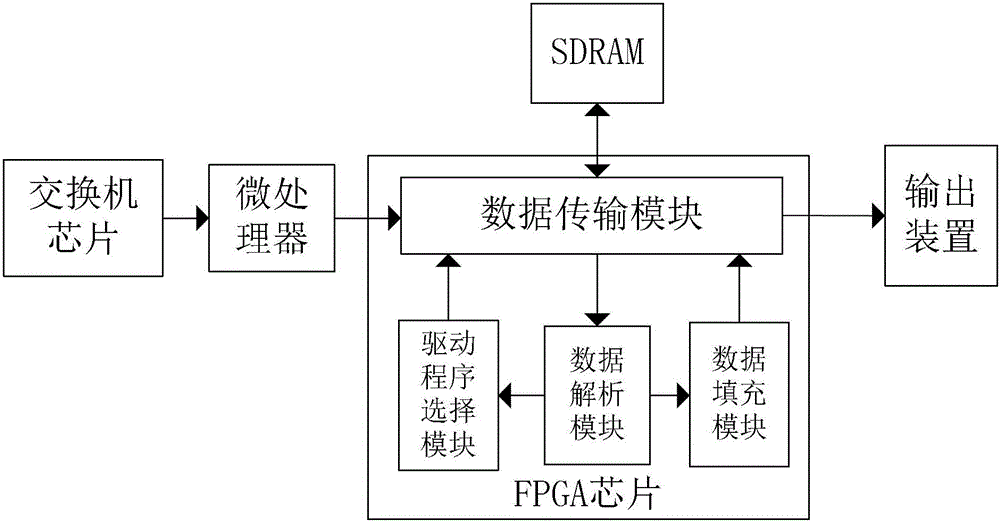

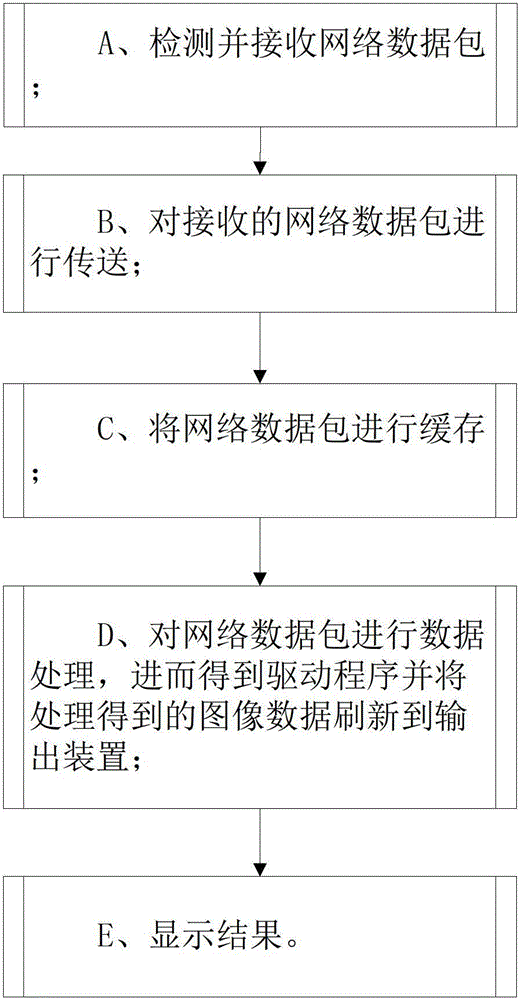

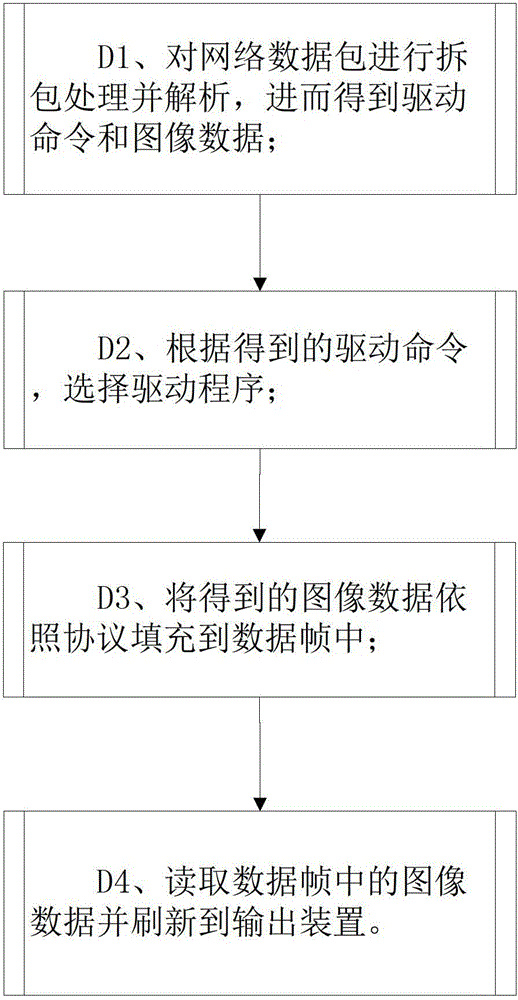

LED intelligent control system and method

ActiveCN103260307BSolve technical problems with poor compatibilityLow costElectric light circuit arrangementEnergy saving control techniquesNetwork packetOutput device

The invention discloses an LED intelligent control system and method. The system comprises a switchboard chip for detecting and receiving network data packages, a microprocessor for transmitting the received network data packages, an output device for displaying results, an FPGA chip for carrying out data processing on the network data packages to obtain drive programs and refreshing processing-obtained image data to the output device, and an SDRAM for data processing buffering and caching the network data packages and the image data. According to the received network data packages, data processing is carried out on the network data packages, then the drive programs are obtained, and the processing-obtained image data is refreshed to the output device. The LED intelligent control system and method can intelligently select the drive programs according to different lamps in a project, and is convenient to use and efficient, cost is greatly saved, stability is high, and difficulty of debugging and maintenance is reduced. The LED intelligent control system and method is applied to control systems.

Owner:广东恒辰光电科技有限公司

Data playback method and device, storage medium and electronic device

ActiveCN108786113BSolve technical problems with poor compatibilityVideo gamesSelective content distributionMediaFLOComputer compatibility

The invention discloses a data playing method and device, a storage medium and an electronic device. Wherein, the method includes: loading a control plug-in in the game engine, wherein the control plug-in is used to create a first data buffer for data interaction with the media player, and the media player is used to decode the source media data to be played in the game engine; Obtain the target media data obtained after the media player decodes the source media data from the first data buffer; Build a media playback model that matches the target media data in the game engine; Paste the target media data on the media playback model to be played in the game engine The target media data is played in the game engine. The invention solves the technical problem of poor compatibility of the game engine caused by the inability of the game engine to be compatible with different audio and video formats.

Owner:TENCENT TECH CHENGDU

Chip testing method and device

ActiveCN105911451BFast test resultsImprove compatibilityProgramme controlElectronic circuit testingComputer hardwareData transmission

The invention discloses a chip test method and a chip test device. The chip test device comprises the test equipment, a chip test circuit board, an input interface which is arranged on the chip test circuit board, is connected with the test equipment and is used for carrying out data transmission between the test equipment and the chip test circuit board, and a controller which is arranged on the chip test circuit board, is connected with a to-be-tested chip and the input interface, is used for acquiring a state instruction of the input interface and determining a corresponding test vector according to the state instruction, wherein the controller is further used for sending a work mode corresponding to the test vector to the to-be-tested chip to make the to-be-tested chip operate in a work mode, the controller is further used for acquiring a work state of the to-be-tested chip operating in the work mode and determining a detection result of the to-be-tested chip according to the work state. Through the method and the device, a technical problem of poor compatibility existing in a chip test device in the prior art is solved.

Owner:ANALOGIX SEMICON (SUZHOU) INC +1

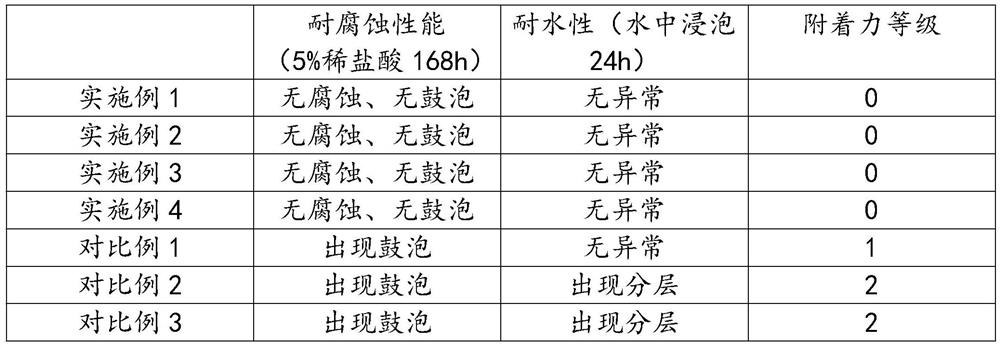

Preparation method of corrosion-resistant environment-friendly coating

InactiveCN112126351AImprove corrosion resistanceSolve technical problems with poor compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsPtru catalystSilicic acid

The invention relates to a preparation method of a corrosion-resistant environment-friendly coating. The preparation method comprises the following steps of: step 1, weighing the following raw materials in parts by weight: 55-75 parts of modified organic silicon, 25-30 parts of an environment-friendly emulsion, 8-15 parts of a nano filler, 1-3 parts of a thickening agent, 0.5-1.5 parts of a stabilizer and 55-60 parts of absolute ethyl alcohol; step 2, adding the modified organic silicon, the environment-friendly emulsion and the stabilizer into the absolute ethyl alcohol to obtain a mixed solution; and 3, adding the nano-filler into the mixed solution prepared in the step 2, and performing dispersing for 30 minutes at the rotating speed of 160-180 r / min to obtain the corrosion-resistant environment-friendly coating. A second intermediate ismixed with dissolved methyl phenyl silicone rubber under the action of tetraethoxysilane serving as a curing agent, and dibutyltin dilaurate servingas a catalyst, and the methyl phenyl silicone rubber is modified, and therefore, the technical problem of poor compatibility of a first intermediate and the methyl phenyl silicone rubber is solved; and moreover, the prepared coating has excellent corrosion resistance.

Owner:谢婉雯

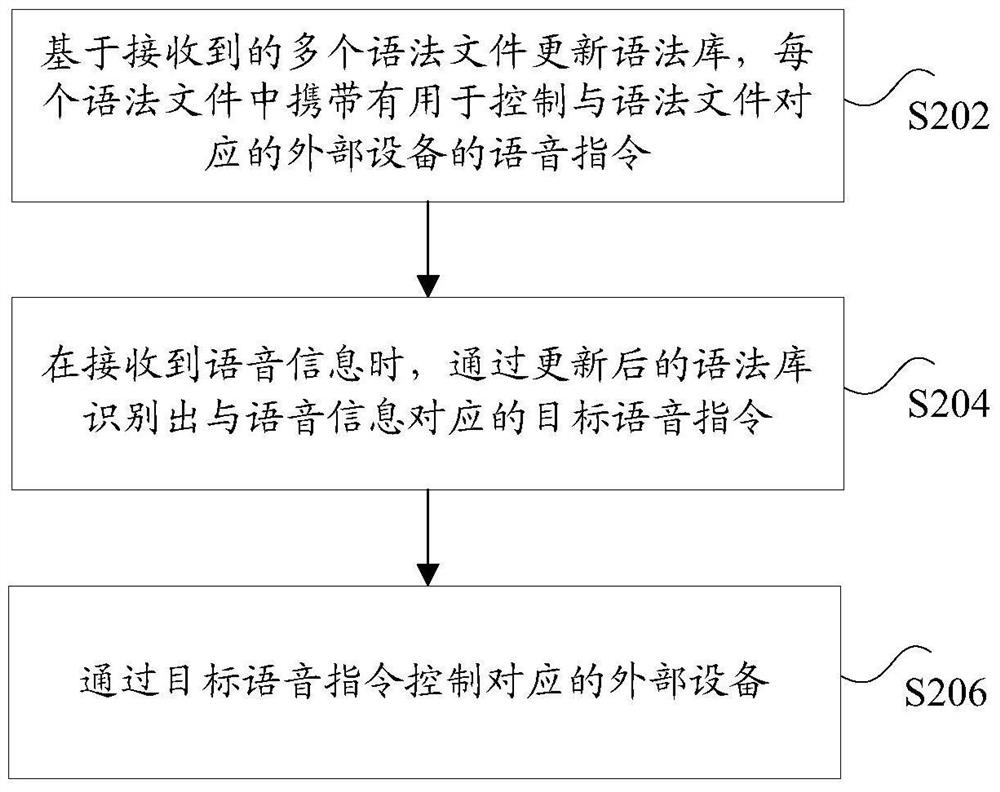

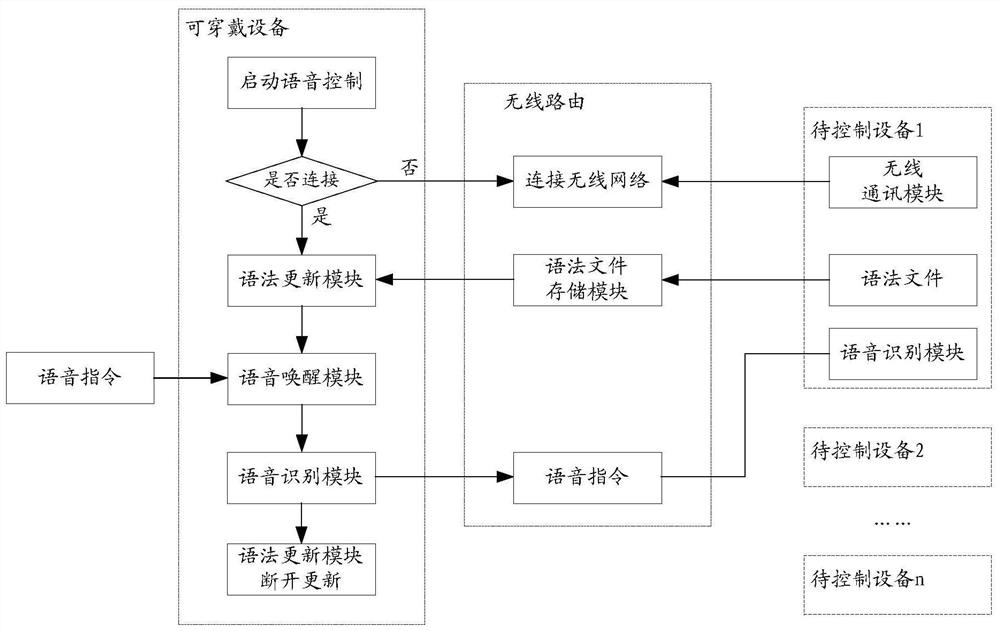

Equipment control method, device and system

ActiveCN107545892BSolve technical problems with poor compatibilityImprove compatibilityDatabase updatingSpeech recognitionProgramming languageSoftware engineering

The invention provides a device control method, device and system. The method includes: updating a grammar library based on a plurality of grammar files received, wherein each grammar file carries a voice instruction for controlling an external device corresponding to the grammar file; The library recognizes the target voice command corresponding to the voice information; and controls the corresponding external device through the target voice command. The invention solves the technical problem of poor compatibility when the wearable device is used for voice control in the related art.

Owner:ZTE CORP

Software application processing method and device

ActiveCN107370804BSolve technical problems with poor compatibilityImprove compatibilityTransmissionOperational systemSoftware engineering

The invention discloses a software application processing method and device. Wherein, the method includes: detecting a predetermined operation performed on the client, wherein the predetermined operation is used to instruct running or downloading a target software application; The type of the operating system of the device; the target software application is run or downloaded through the web page interface of the built-in browser of the client under the type of operating system. The invention solves the technical problem of poor compatibility between the application pushed to the user and the terminal equipment used by the user in the related art.

Owner:TENCENT TECH (SHENZHEN) CO LTD

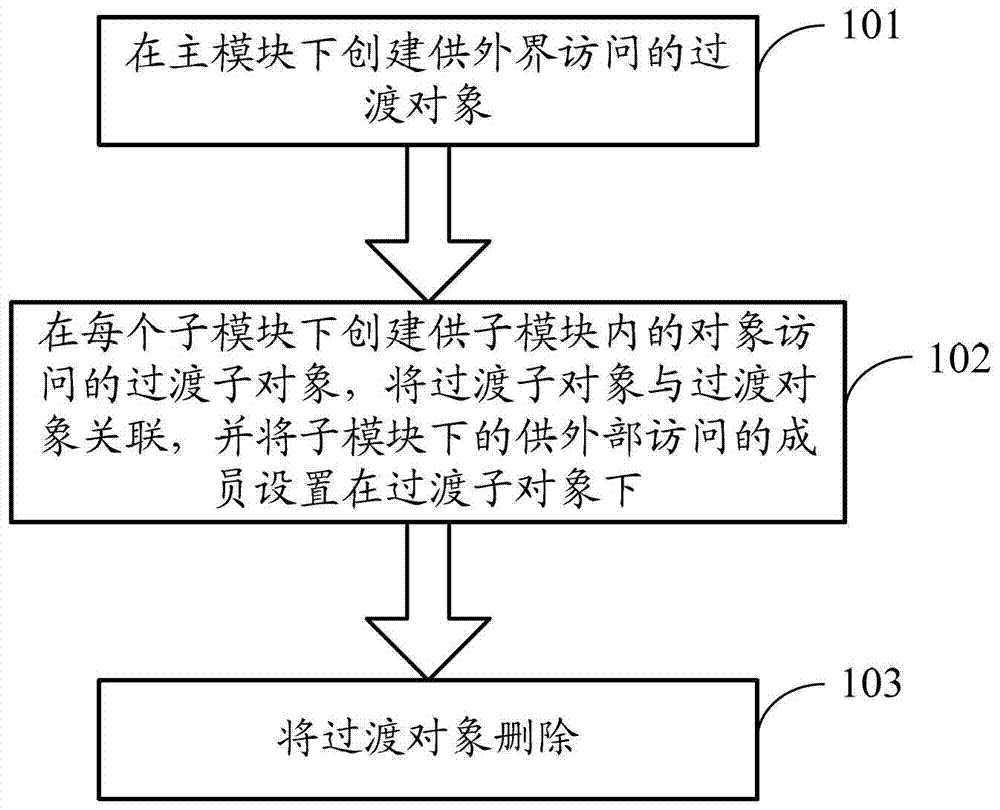

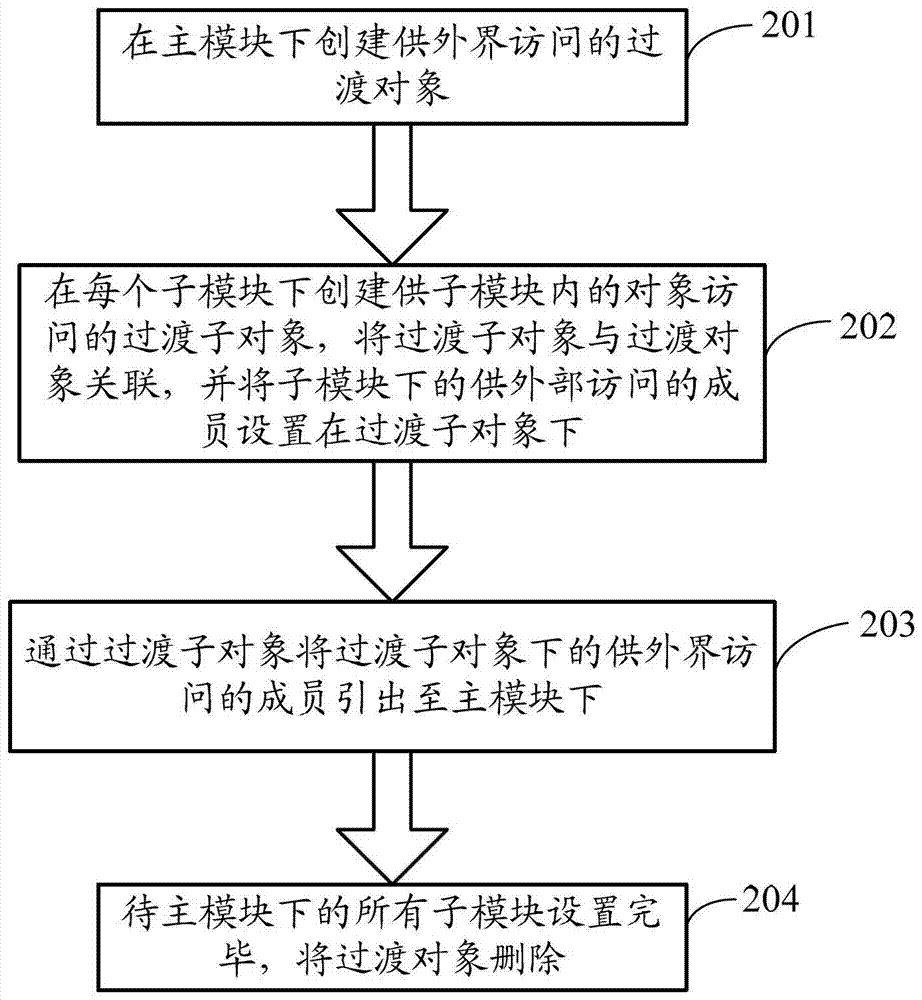

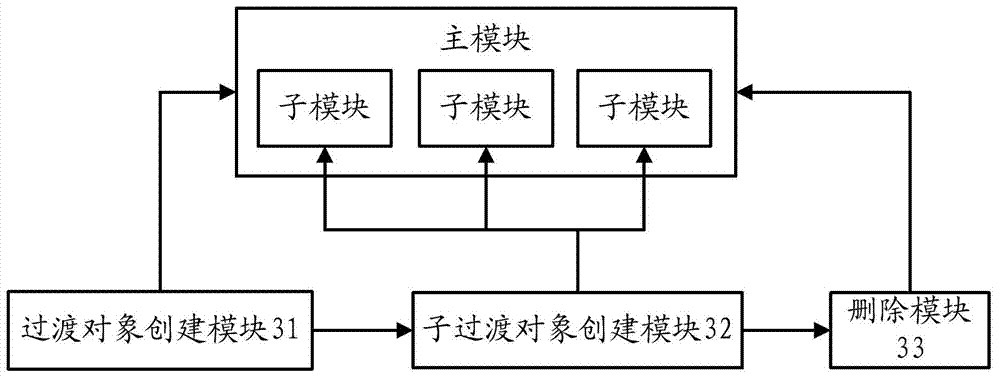

Module group creation method and device

ActiveCN103902308BImprove compatibilitySolve technical problems with poor compatibilityProgram loading/initiatingComputer engineering

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com