Anti-flooding gate control cabinet

An anti-flooding door and control cabinet technology, applied in electrical program control, program control in sequence/logic controllers, door/window accessories, etc., can solve control failures, high stability requirements, and equipment component failures and other problems to achieve the effect of reducing the possibility of failure, improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in combination with real-time methods and accompanying drawings.

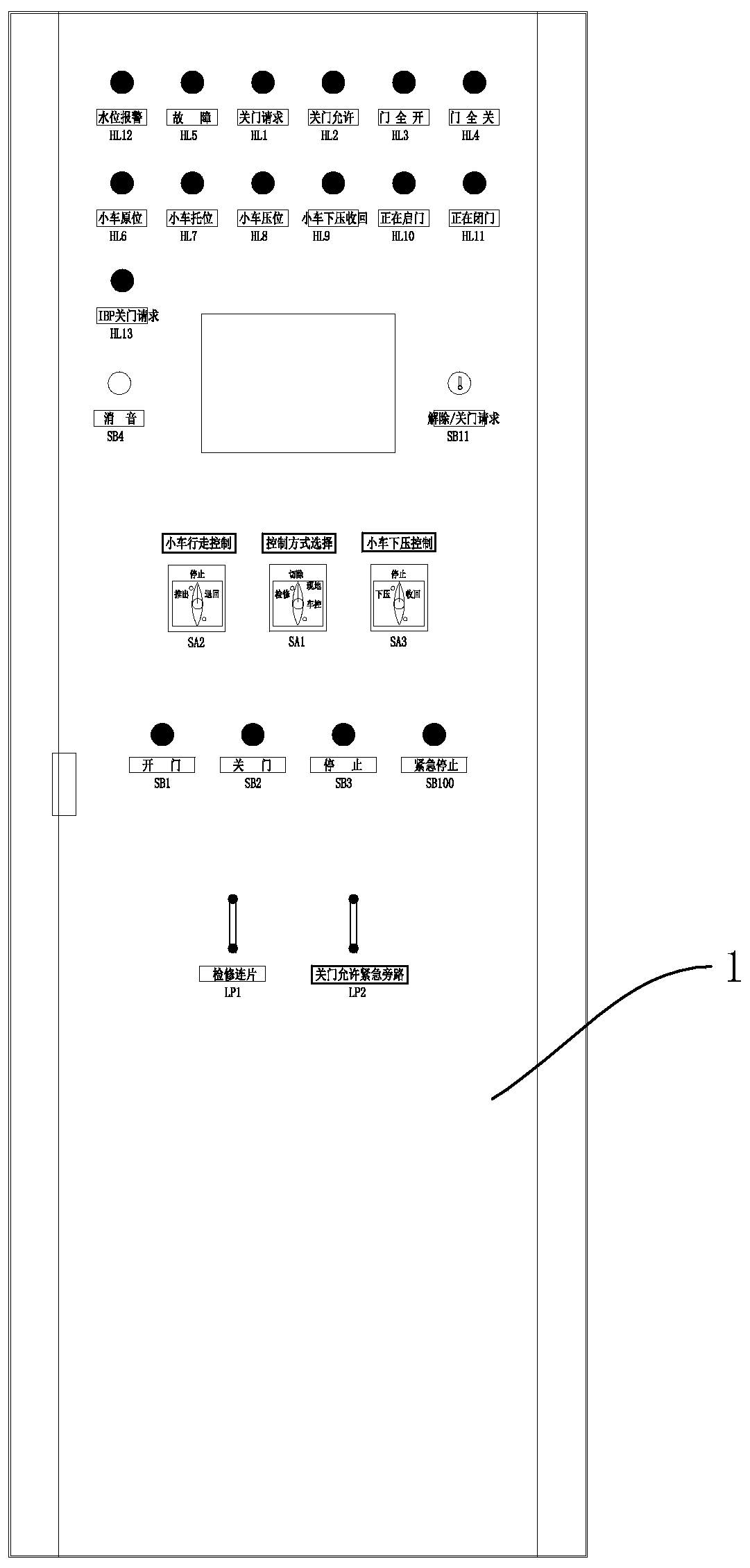

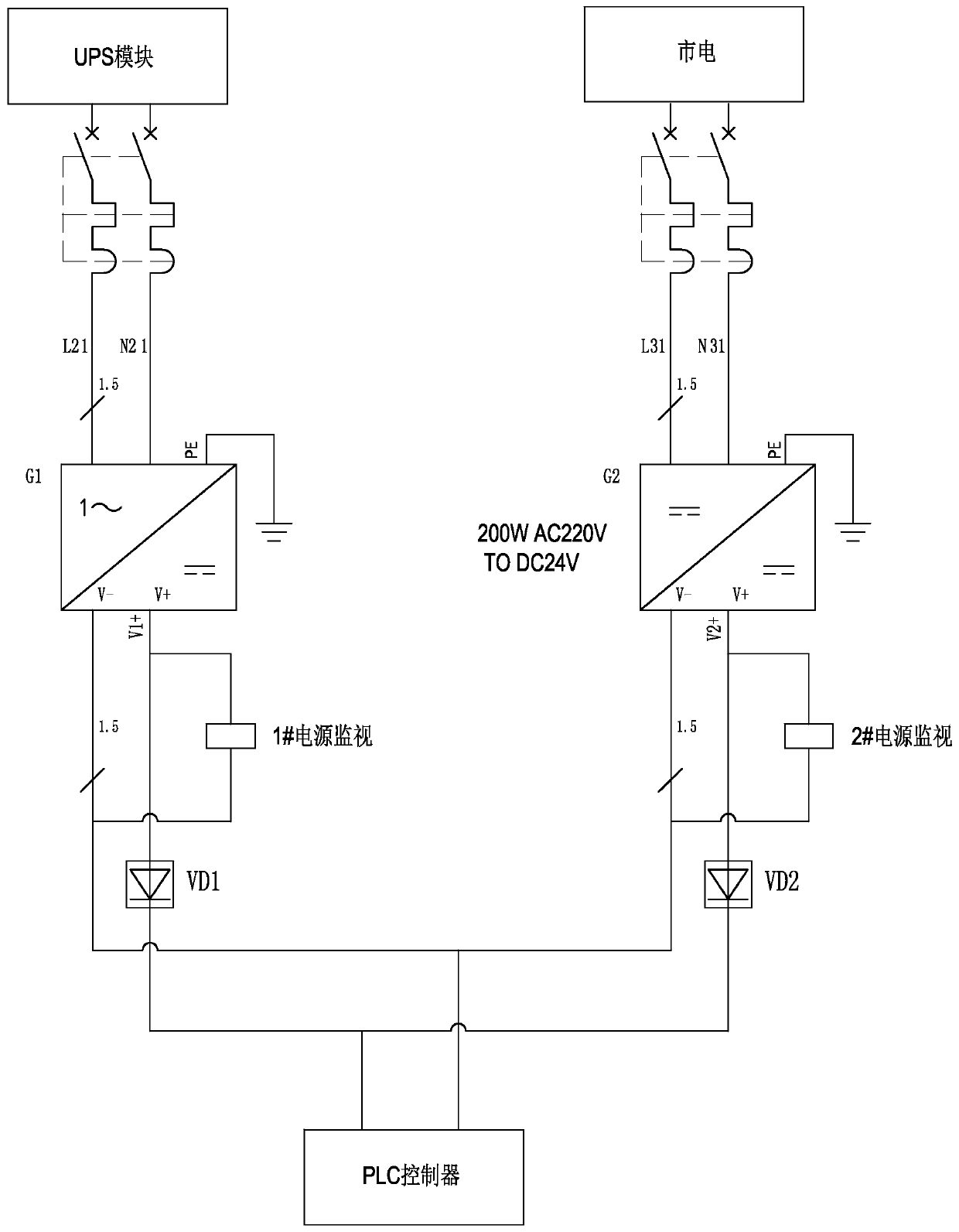

[0027] Such as Figure 1-Figure 5 Shown is an anti-flood door control cabinet of the present invention, the anti-flood door power system, including: a cabinet body 1, a power module 2 arranged in the cabinet body 1, a PLC controller 3, an ATC system interface 4, and a vehicle control room IBP Disk interface 5, conventional communication interface 6, anti-shelter door control module 7 and temperature and humidity control module 8.

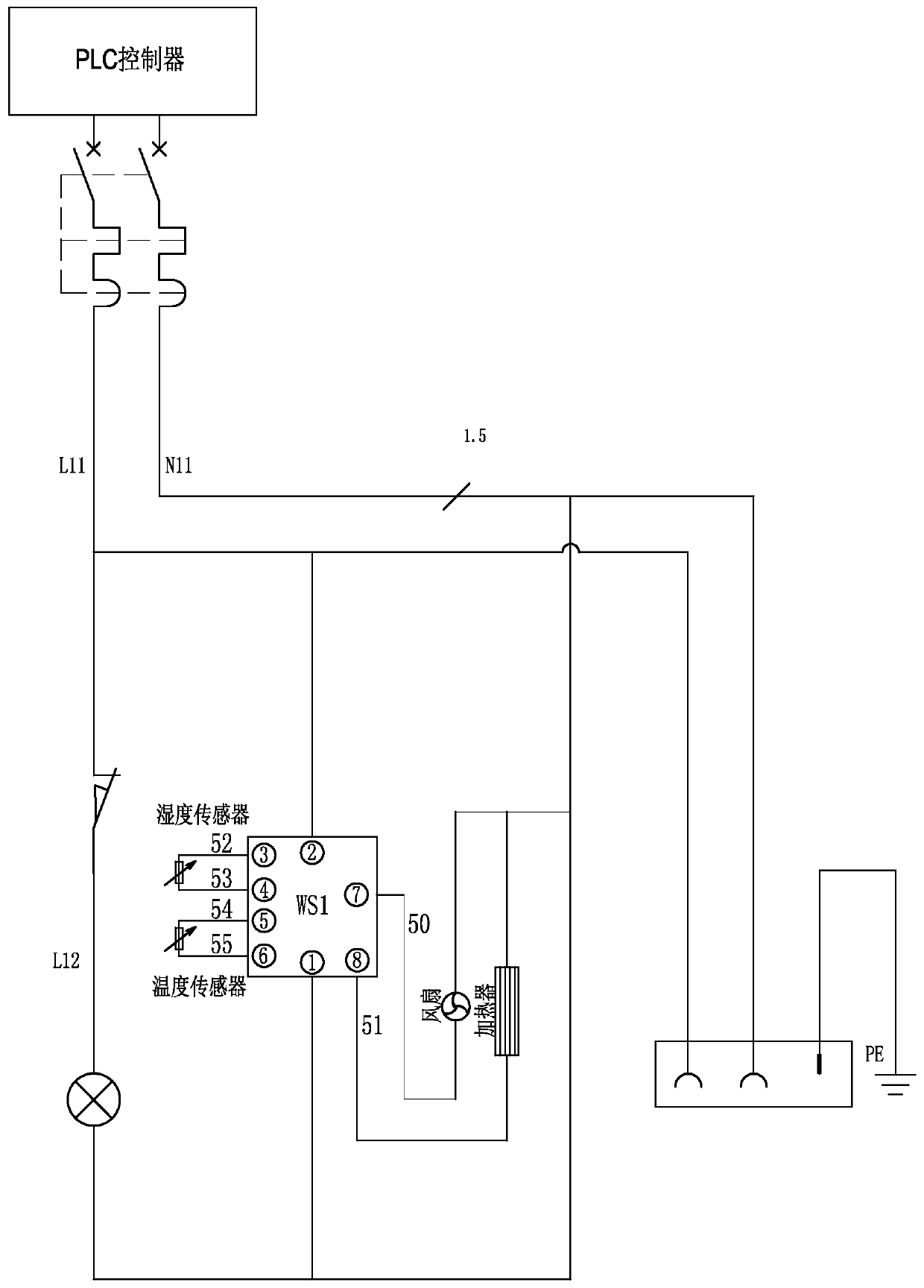

[0028] Such as figure 2 As shown, the temperature and humidity control module 8 includes a temperature sensor, a humidity sensor, a fan and a heater respectively connected to the PLC controller 3, and the temperature and humidity sensors are set in the cabinet, and the PLC controller 3 controls the fan and the heater simultaneously. oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com