A magnetically controlled damper with high-frequency anti-shock energy dissipation characteristics

A damper and characteristic technology, applied in the field of structural vibration reduction, can solve the problems of single operating frequency and inability to effectively control different excitation frequencies, and achieve the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

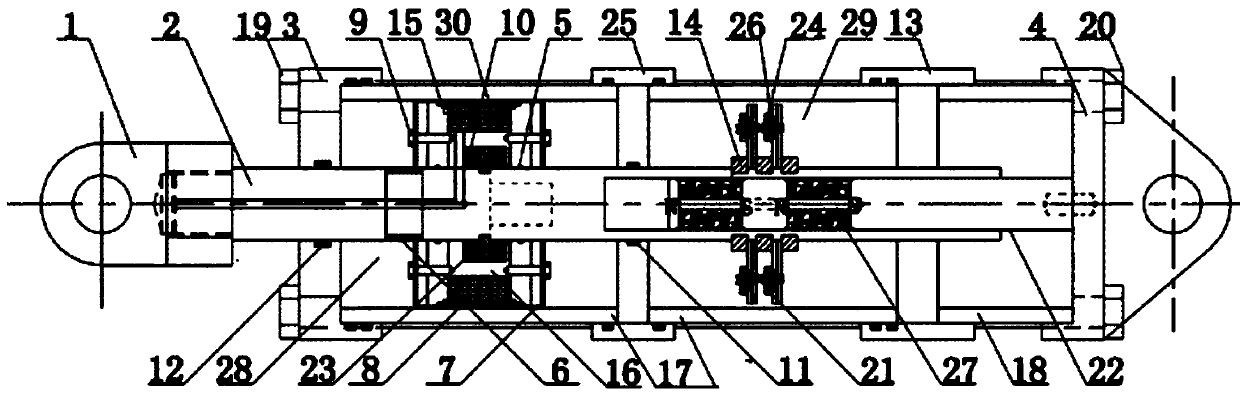

[0035] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0036] A magnetically controlled damper with high-frequency anti-shock energy consumption characteristics, comprising a main piston rod 22 and an auxiliary piston rod 2, the main piston rod 22 is connected to the auxiliary piston rod 2; the main piston rod 22 is connected to the auxiliary piston rod The rod 2 is arranged in the master cylinder 17;

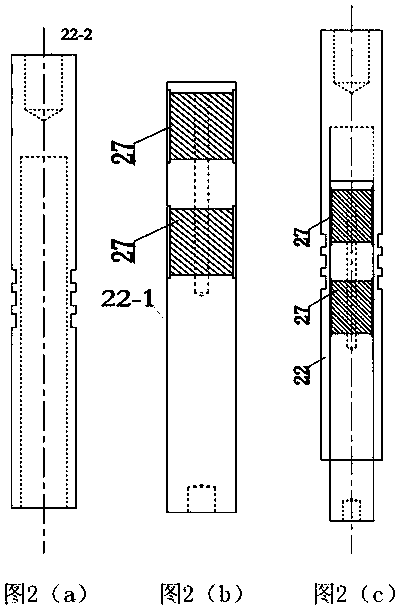

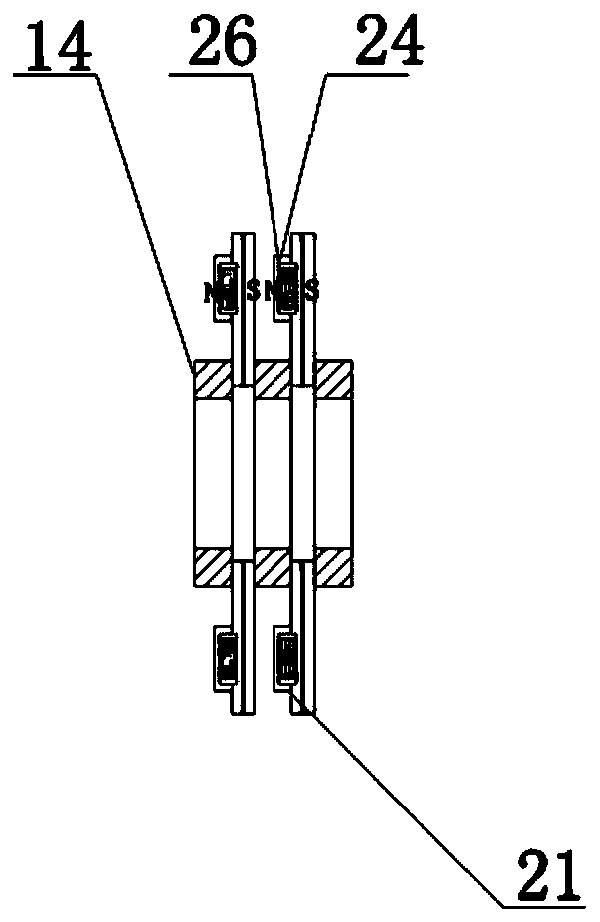

[0037] In conjunction with accompanying drawing 2 (a), accompanying drawing 2 (b), accompanying drawing 2 (c) and accompanying drawing image 3 , the main piston rod 22 includes a main piston inner rod 22-1 and a main piston outer rod 22-2; a blind hole A is provided inside the main piston outer rod 22-2, and a main piston inner rod 22-2 is arranged in the blind hole A 1. One end of the inner rod 22-1 of the main piston is provided with a blind hole, and two ring-shaped permanent magnets 27 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com