Wiring harness movement preventing wire clamp for vehicle lamps

A technology of automotive lamps and defense lines, which is applied in the field of auto parts, can solve the problems of inconvenient rope operation, short-circuit fire, and circuit breaker shutdown, etc., to reduce the risk of damage and failure, prevent random shaking, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

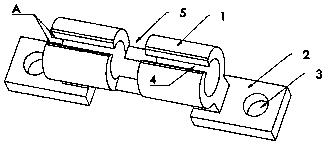

[0011] Depend on figure 1 Known, a kind of anti-wiring wire clip for automobile lamps and lanterns, comprises wire clip body, and wire clip body is made of nylon plastic material; The mounting feet 2 at both ends of the bottom of the body 1 are composed of mounting holes 3; the top of the circular pipe body 1 is provided with an inlet 4, and the faces A on both sides of the inlet 4 are inclined surfaces, so that the inlet The line opening 4 is wide at the top and narrow at the bottom. The width of the narrow opening of the line entrance 4 is between 0.75-1mm, and the angle of surface A is above 30 degrees, which is convenient for the wire harness to be pressed into the circular tube body 1. Due to the width of the narrow opening Between 0.75-1mm, it can well prevent the wire harness from detaching from the circular pipe body 1; the circular pipe body 1 is provided with a cutout 5 in the middle, so that the circular pipe body 1 forms two clamping bodies, and passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com