Magnetic-force-based rapid clamping device for measuring shell parts

A clamping device and parts technology, which is applied in the field of fast clamping devices for shell parts measurement, can solve the problems of poor positioning accuracy of parts and poor reliability of fixing methods, and achieve improved reliability, strong pertinence, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to implement the present invention better, the present invention is described in detail below in conjunction with accompanying drawing of description:

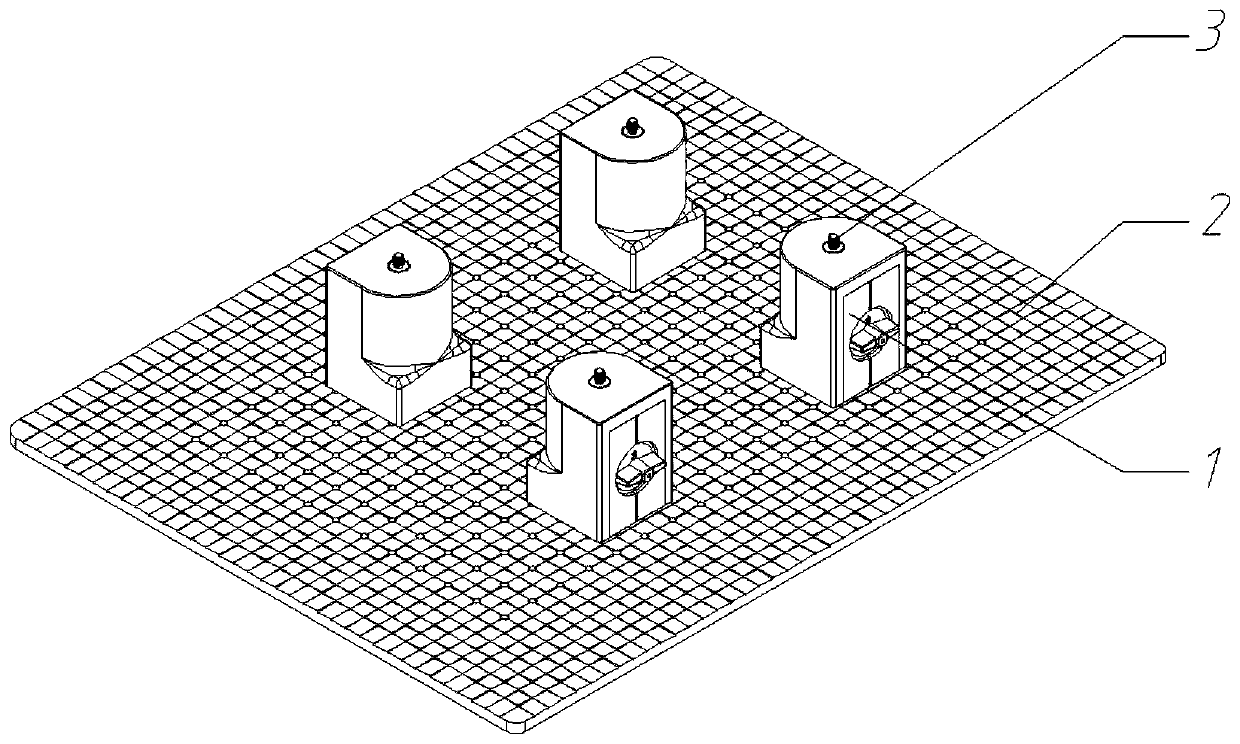

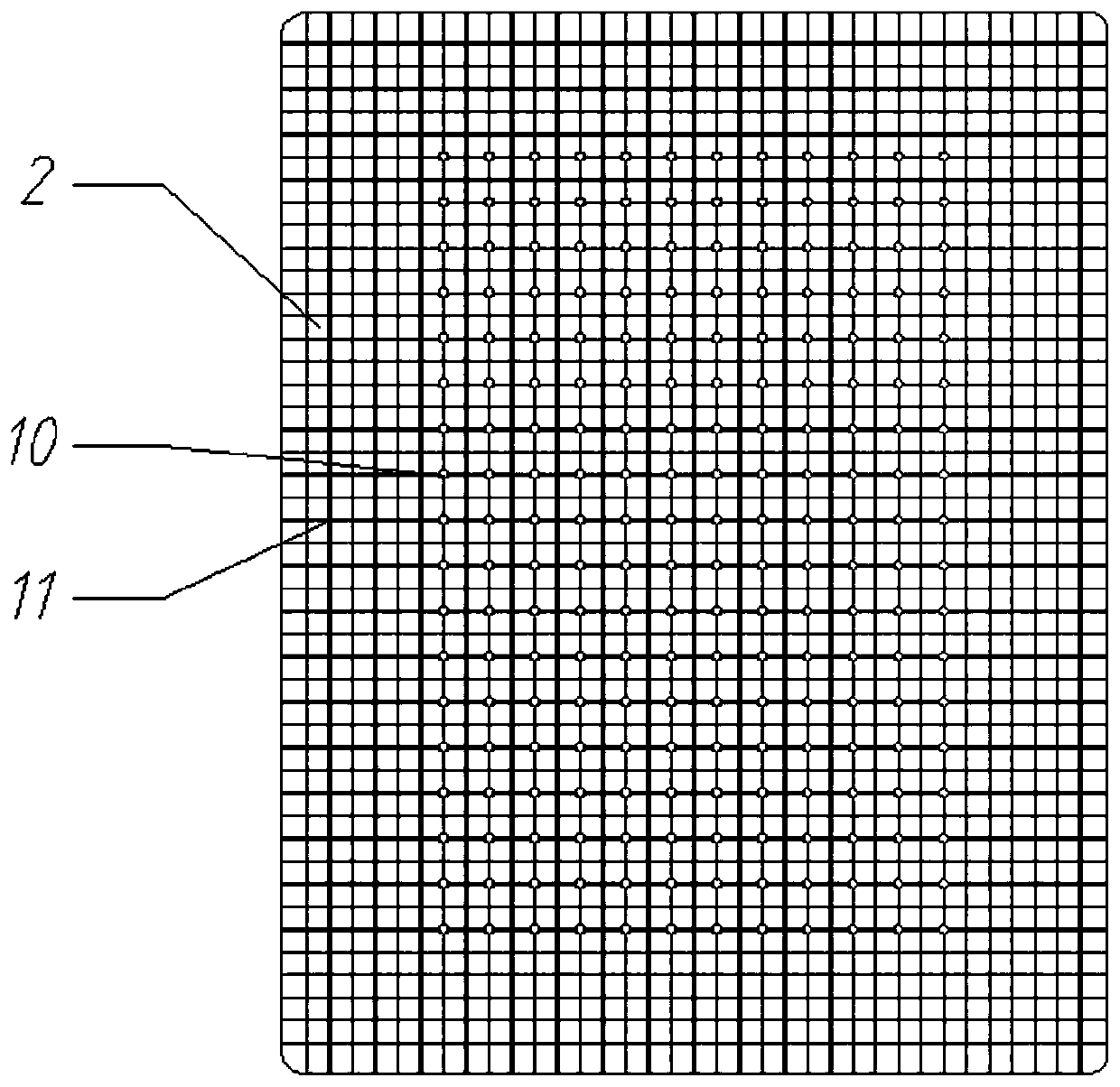

[0023] The utility model relates to a quick clamping device for measuring shell parts on platform measuring equipment such as a three-coordinate measuring machine. Such as figure 1 As shown, including: magnetic base 1, positioning substrate 2, magnetic connector 3

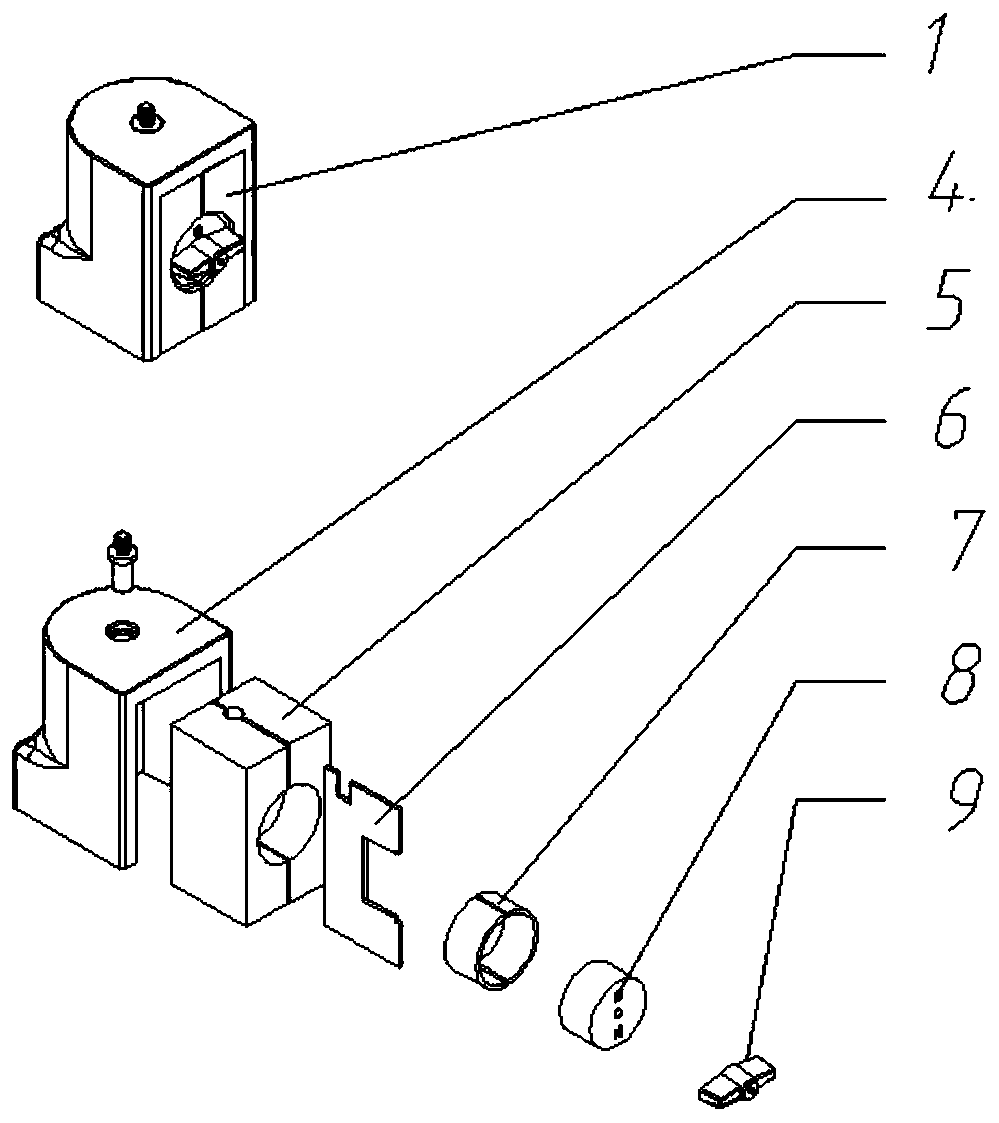

[0024] Magnetic base 1 is the core part of the device, with a structure such as figure 2 As shown, place it on the positioning substrate 2, fix the magnetic connector 3 and the threaded hole on the bottom surface of the part through threaded connection, and then place it on the magnetic base 1 along with the parts, so that the circular tenon of the magnetic connector 3 is inserted into the magnetic base 1 In the fixing hole, adjust the magnetic base 1 to the required position on the positioning substrate 2, turn on the magnetic switch to attract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com