Pipe fitting paint spraying equipment capable of quickly fixing pipe fitting based on constructional engineering

A technology of construction engineering and painting equipment, applied in the direction of spraying devices, etc., can solve the problems of poor uniformity, time-consuming and laborious, and the valve at the sewage outlet is easily blocked by debris, so as to achieve good uniformity and improve operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

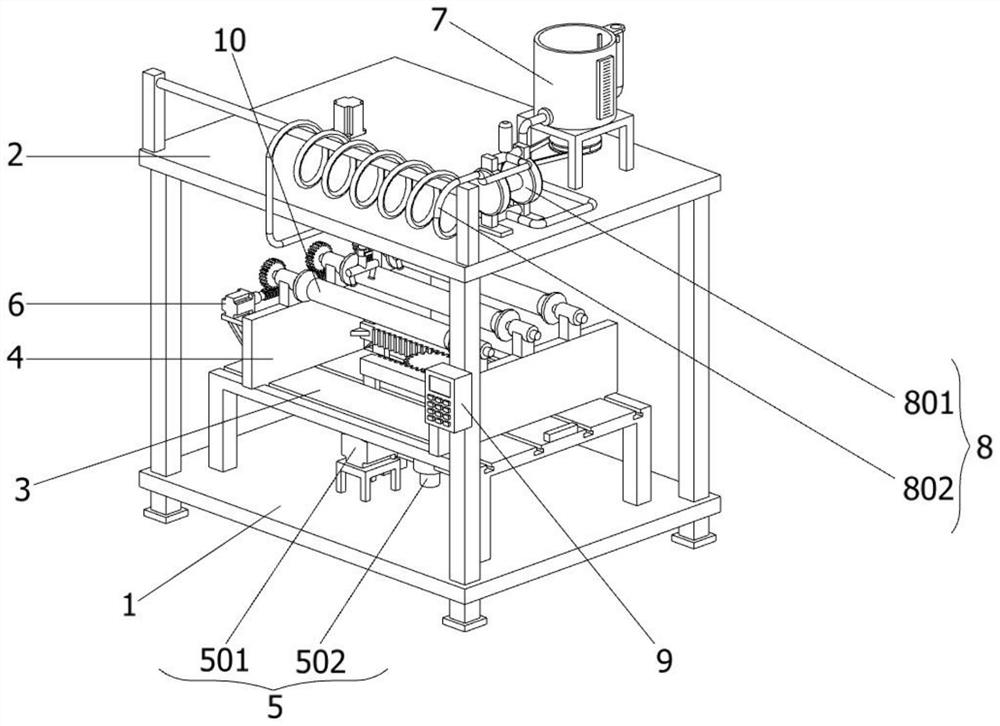

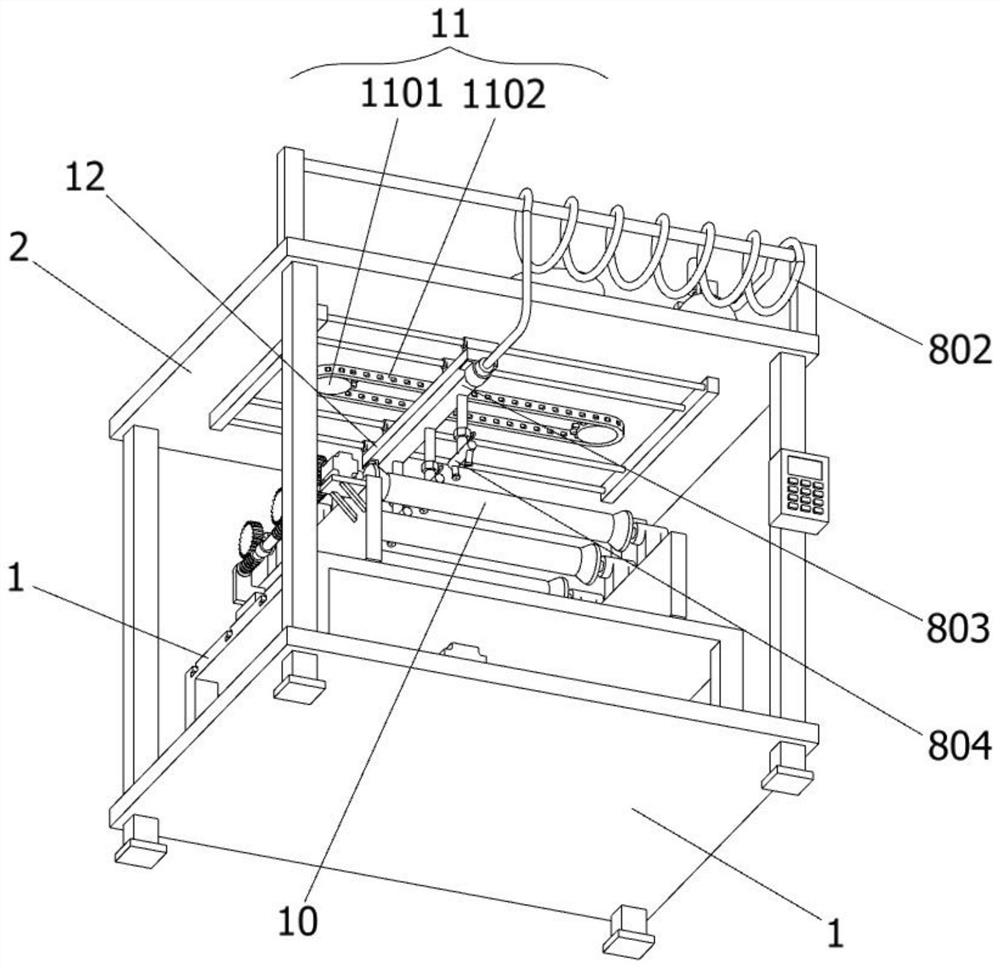

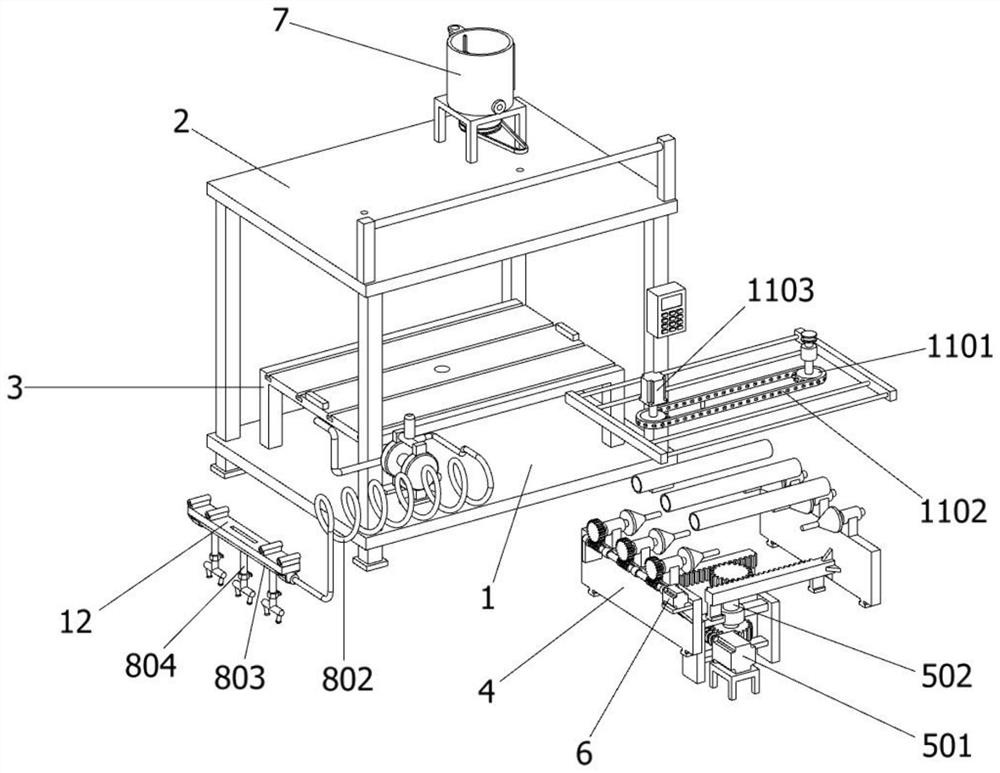

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The invention provides a pipe fitting painting equipment based on construction engineering that can quickly fix pipe fittings, including: a base 1, the upper part of the base 1 is fixedly connected with a top plate 2 through four support columns, and a support platform 3 is installed on the upper end of the base 1; The upper end surface of the platform 3 is provided with two clamping mechanisms 4 in an annular array, and the bottom of the support platform 3 is located on the upper surface of the base 1 and is provided with a clamping drive mechanism 5; the clamping drive mechanism 5 includes a drive motor 501, a drive shaft 502, a A worm wheel 503, a driving gear 504 and a first worm 505, the driving motor 501 is installed on the upper end surface of the base 1 through a support, and the driving motor 501 is connected to the first worm 505 through a rotating shaft, and the driving shaft 502 is connected to the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com