Sorting mechanical arm

A technology of manipulators and chassis, applied in the field of manipulators, can solve problems such as manual sorting is prone to errors, limits production efficiency, and manual sorting cannot meet production speed, so as to improve sorting speed, improve production efficiency, and reduce sorting errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be described in detail below with reference to the accompanying drawings and examples.

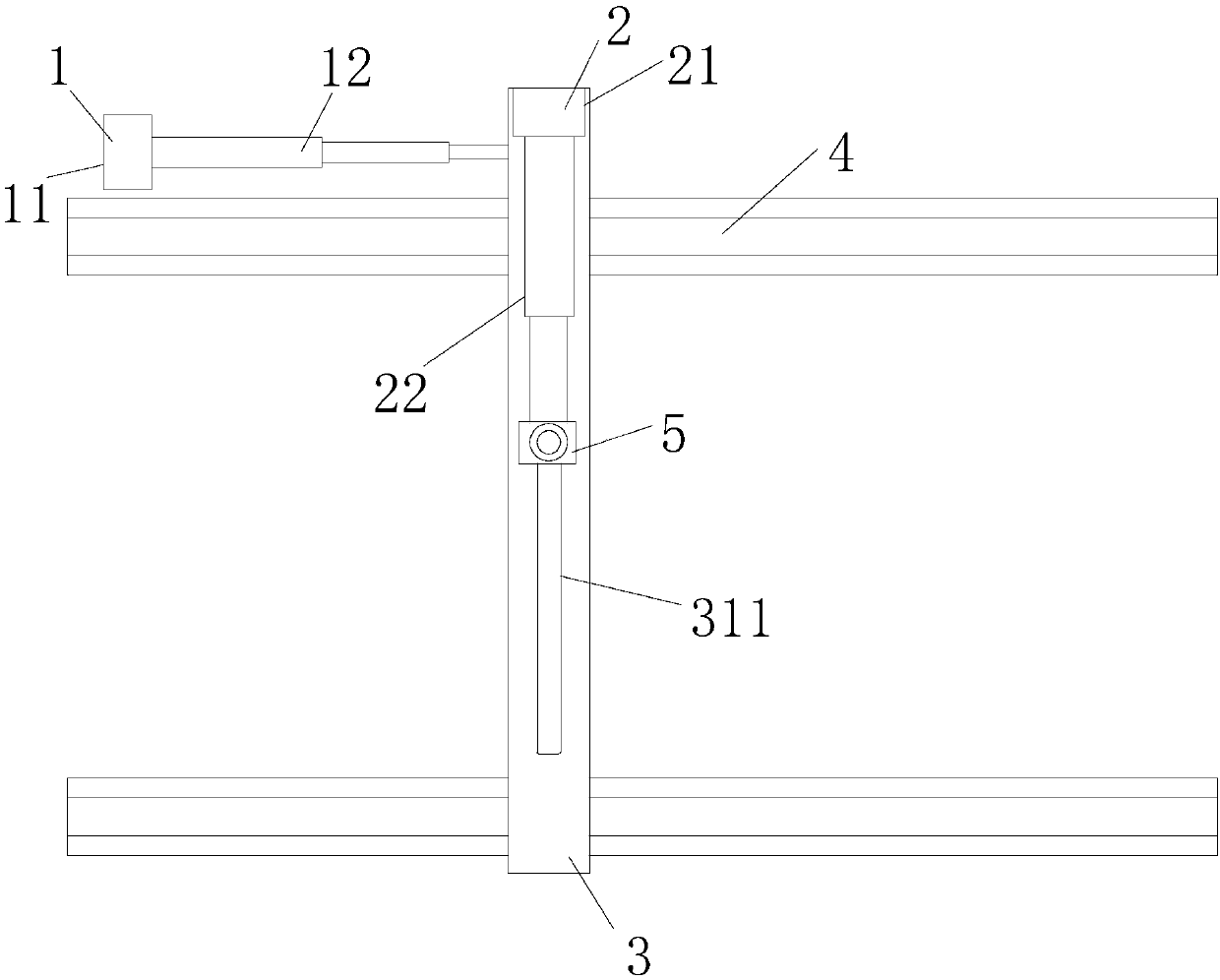

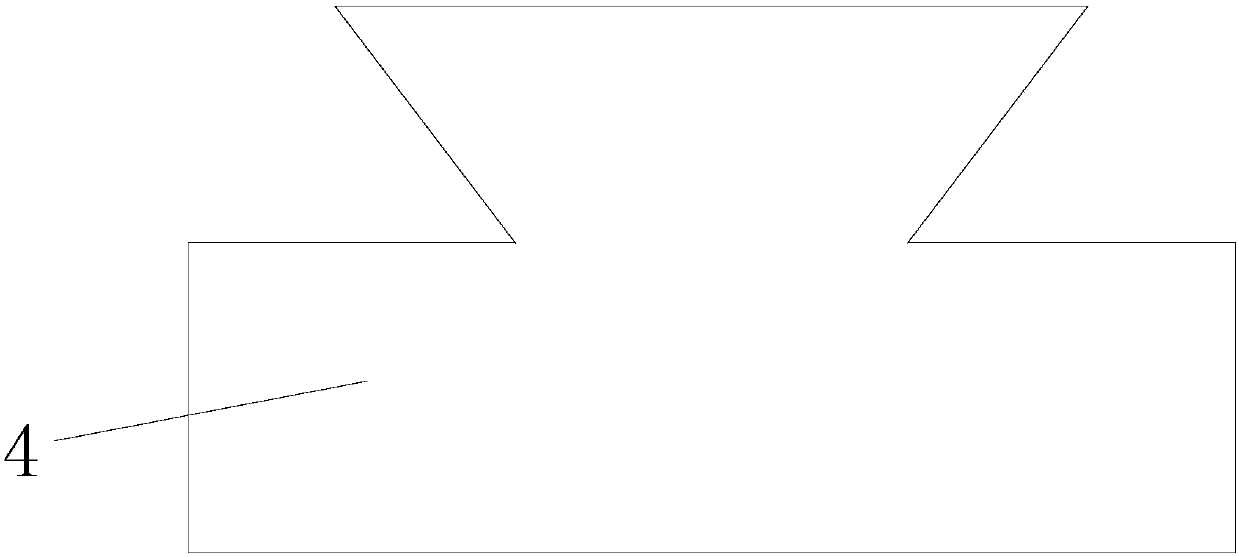

[0022] like Figure 1-4 As shown, a sorting manipulator, the manipulator includes: a first telescopic mechanism 1, a second telescopic mechanism 2, a transverse track 3, a longitudinal track 4 and an operating mechanism 5, and the first telescopic mechanism 1 is located on the longitudinal track 4, the transverse track 3 is located above the longitudinal track 4, the second telescopic mechanism 2 is located above the transverse track 3, and the operating mechanism 5 is located at the top of the second telescopic mechanism 2;

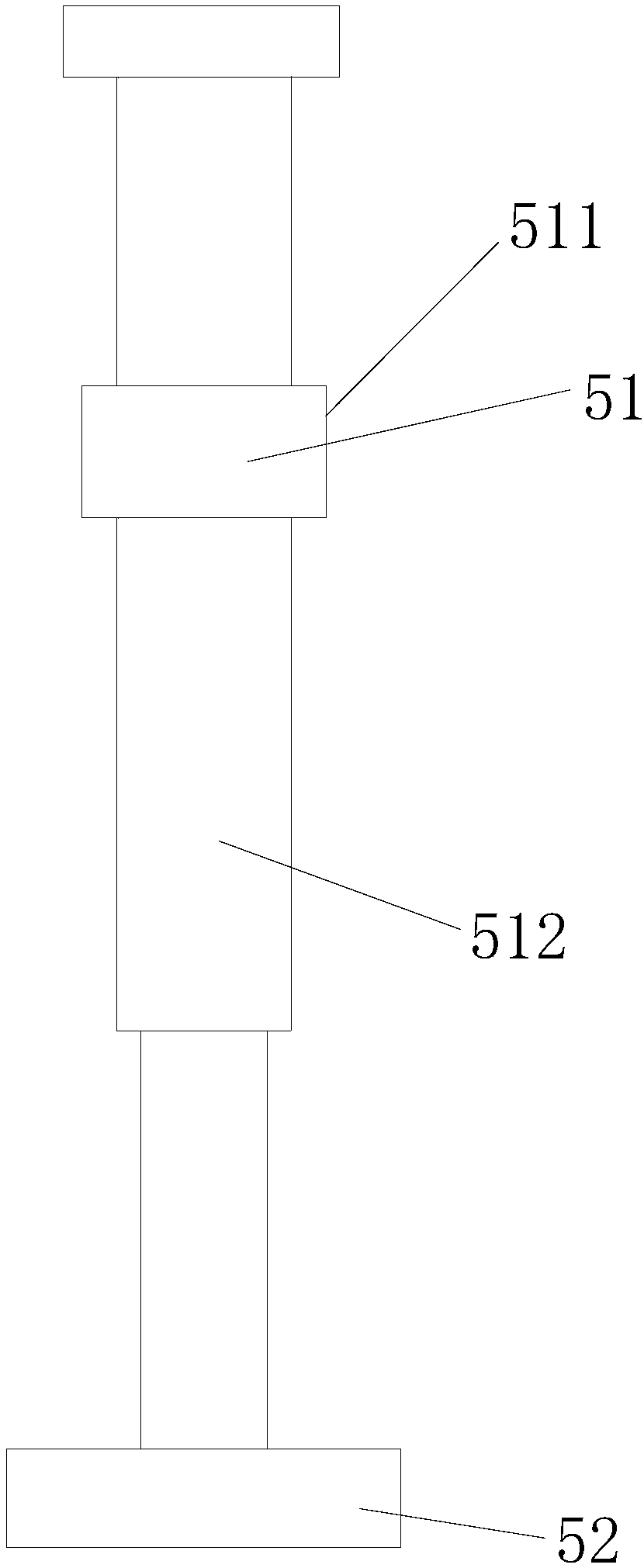

[0023] The operating mechanism 5 includes: a third telescopic mechanism 51 and a suction cup 52, the third telescopic mechanism 51 includes a third casing 511 and a third telescopic rod 512, and the third casing 511 is fixed on the second telescopic rod 22 , one end of the third telescopic rod 512 is fixedly connected to the third chassis 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com