Camera module

A camera module and lens holder technology, which is applied in the parts and electrical components of TVs and color TVs, can solve the problems of loose lens barrels, unstable bonding force of the adhesive layer, and poor image quality of the camera module. The effect of increasing the coating area and enhancing the bonding and fixing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

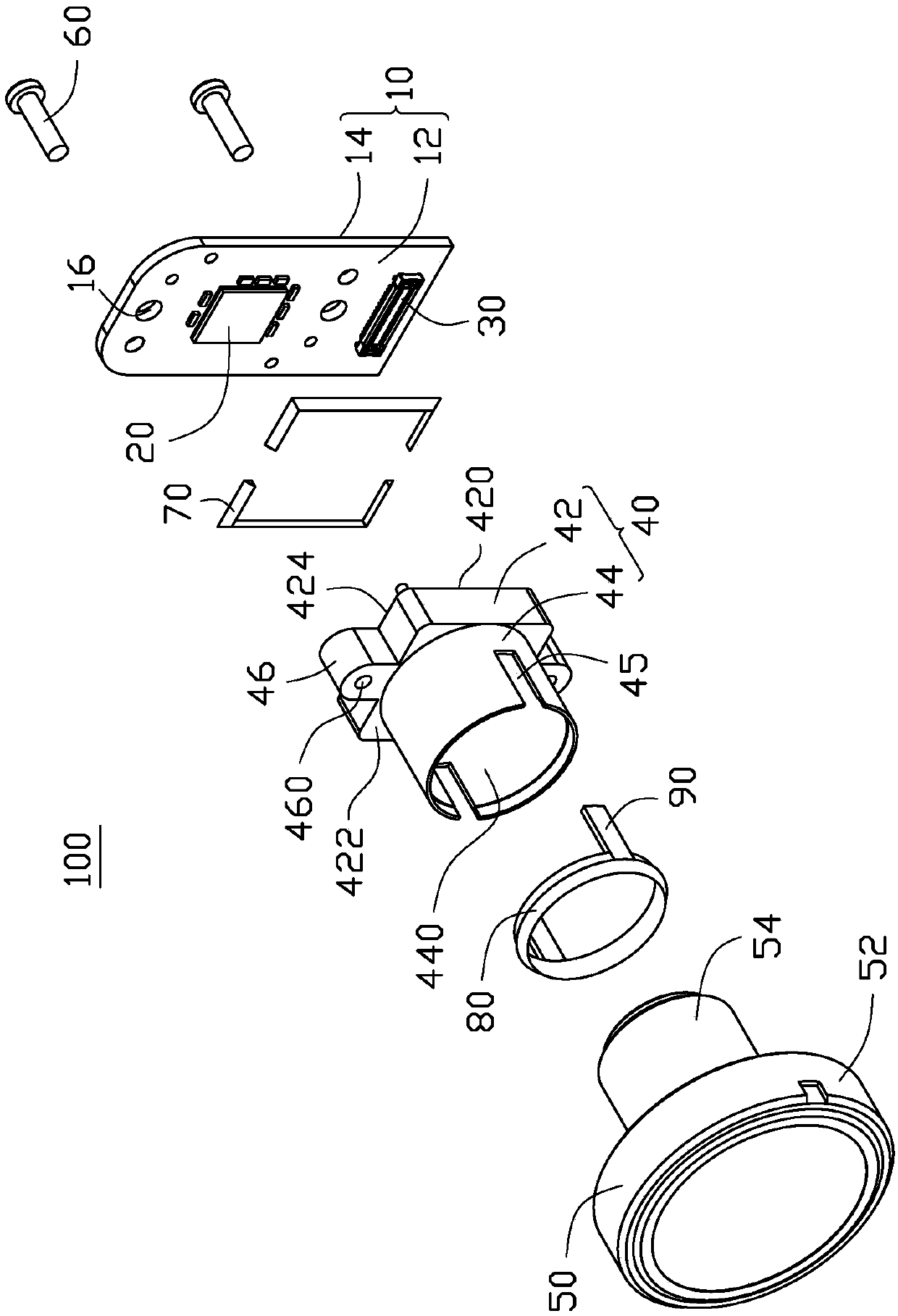

[0014] The first embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

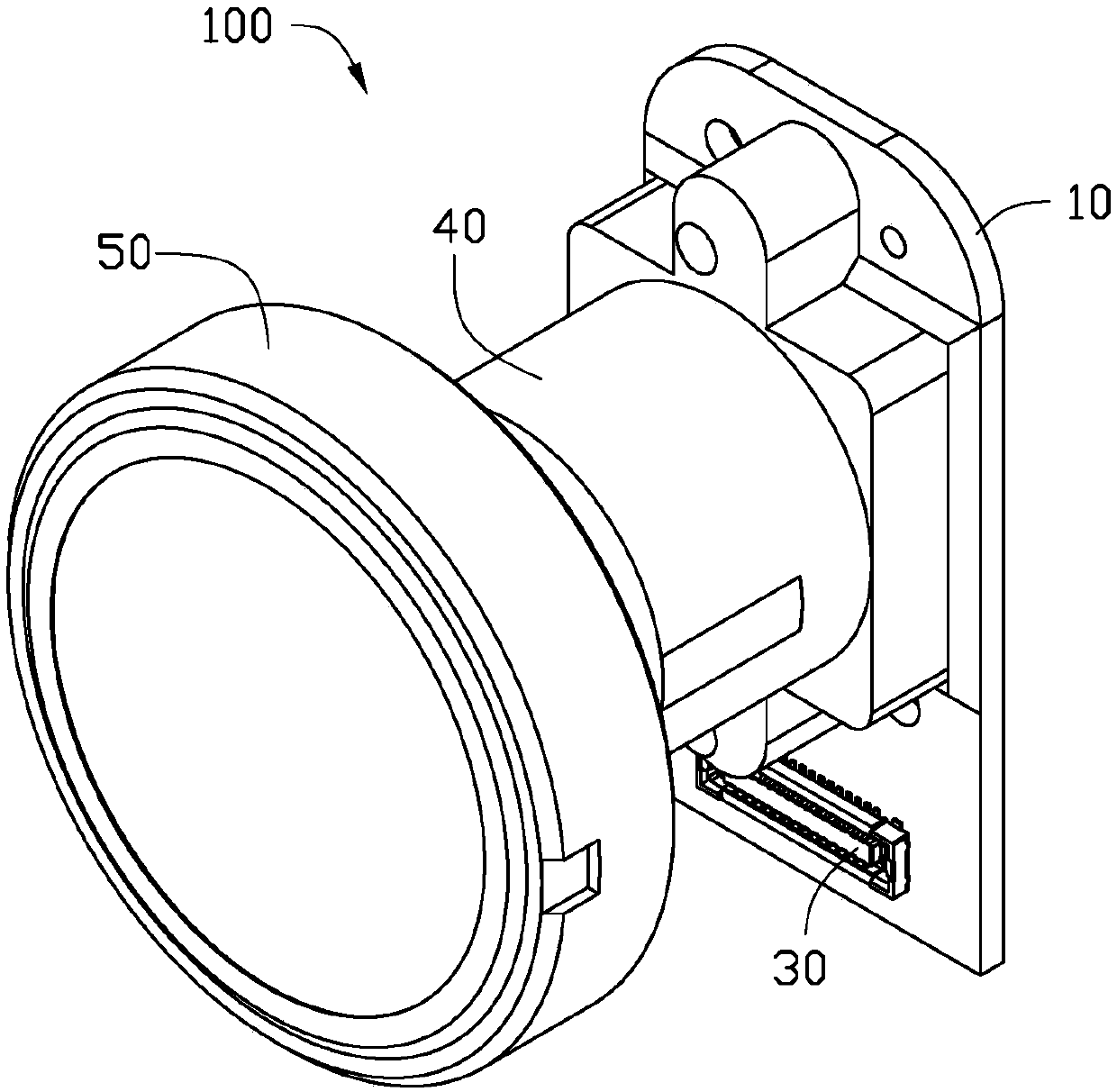

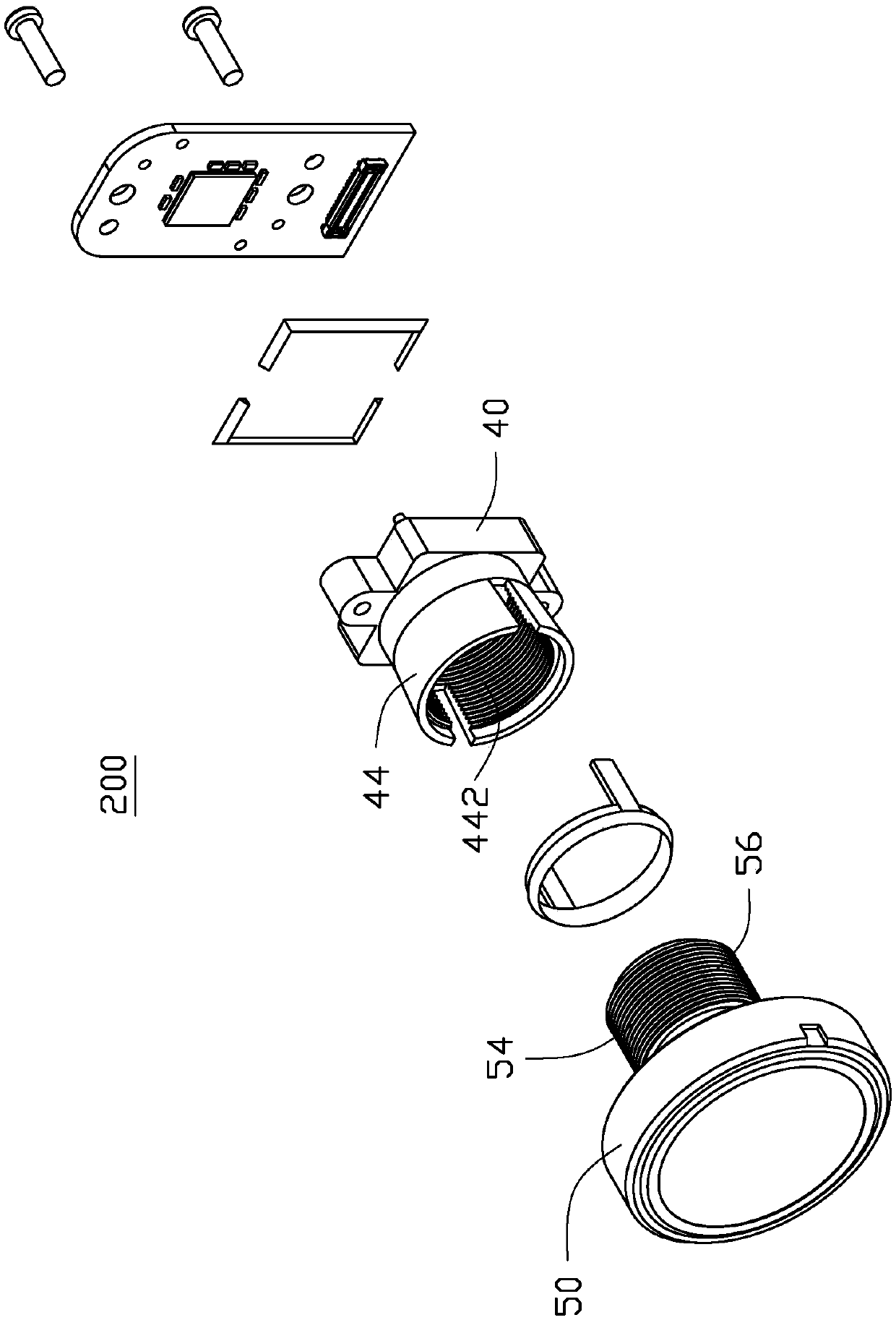

[0015] see figure 1 and figure 2 , is the camera module 100 provided by the embodiment of the present invention. The camera module 100 includes a substrate 10 , an image sensor 20 , a capacitor 30 , a lens holder 40 and a lens barrel 50 .

[0016] The substrate 10 is a circuit board. The substrate 10 includes an upper surface 12 and a lower surface 14 . The upper surface 12 and the lower surface 14 are located on opposite sides of the substrate 10 . In this embodiment, the upper surface 12 is parallel to the lower surface 14 . The substrate 10 defines two mounting holes 16 .

[0017] The image sensor 20 is disposed on the substrate 10 and electrically connected to the substrate 10 .

[0018] The capacitor 30 is disposed on the upper surface 12 of the substrate 10 and is electrically connected to the substrate 10 .

[0019] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com