Conductive adhesive, cylindrical lithium ion secondary battery and preparation method of cylindrical lithium ion secondary battery

A technology of conductive glue and conductive agent, which is applied in the field of energy storage batteries, can solve the problems of reducing battery energy density, increasing battery temperature, and dust puncturing the diaphragm, achieving the effects of improving consistency, large specific surface area, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

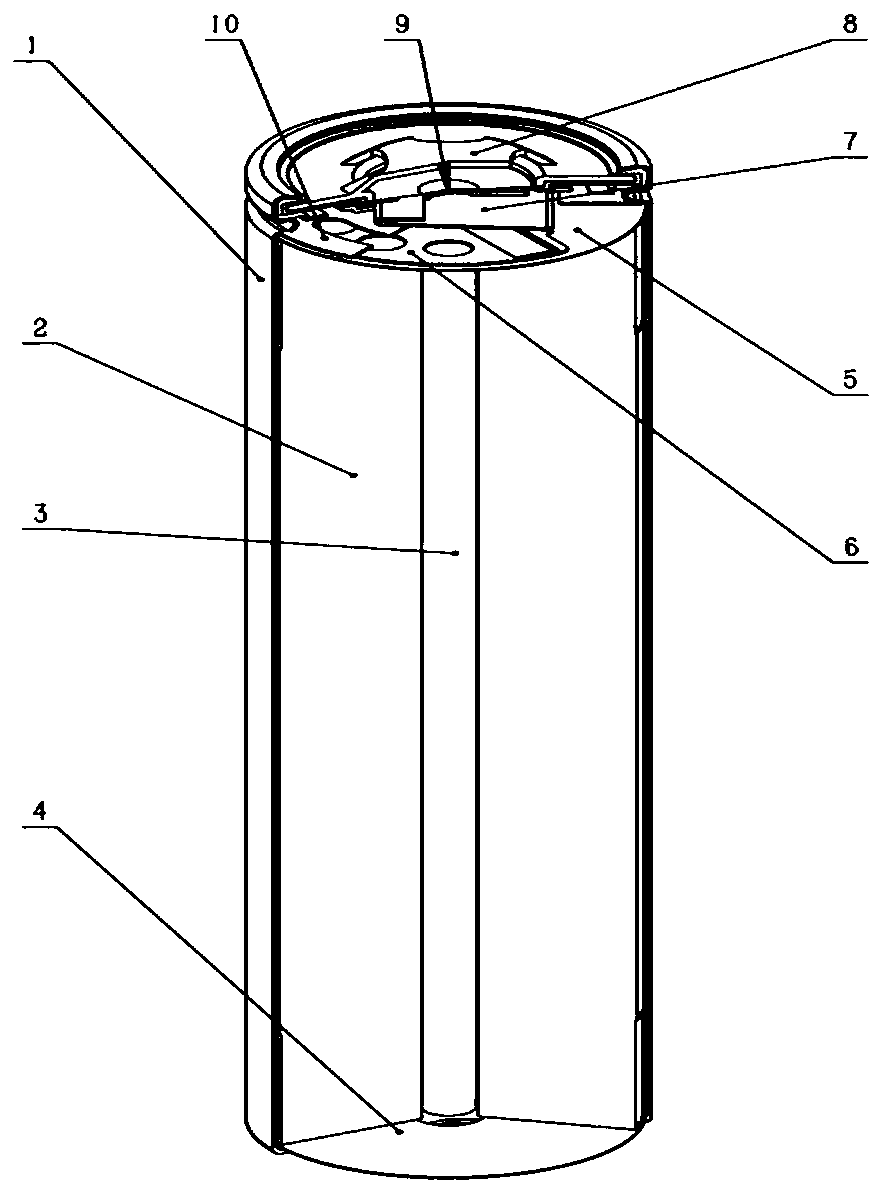

[0044] Embodiment 1 provides a kind of large size power type cylindrical lithium ion battery, such as figure 1 As shown, it includes a battery case 1, an electrode group 2 arranged in the battery case 1, a central steel pipe 3 in the electrode group 2, a first conductive glue 4 coated on the negative end surface of the electrode group 2, a coated The second conductive glue 5 on the positive end surface of the pole group 2, the positive electrode collector plate 6, the positive electrode tab 7 on the positive electrode collector plate 6, the combined cap 8 and the CID sheet 9 in the combined cap 8; the positive electrode The material of the current collecting plate 6 is aluminum alloy, the material of the positive electrode tab 7 is aluminum alloy, the positive electrode current collecting plate 6 and the positive electrode tab 7 are fixed by laser welding, and the positive electrode current collecting plate 6 and the positive electrode tab 7 An insulating spacer 10 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com