Domestic waste solid-liquid separation equipment

A technology for solid-liquid separation and domestic waste, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve problems such as troublesome cleaning, sanitation and safety, silting or blockage of sewer pipes, etc., to facilitate self-cleaning, improve Scalability, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

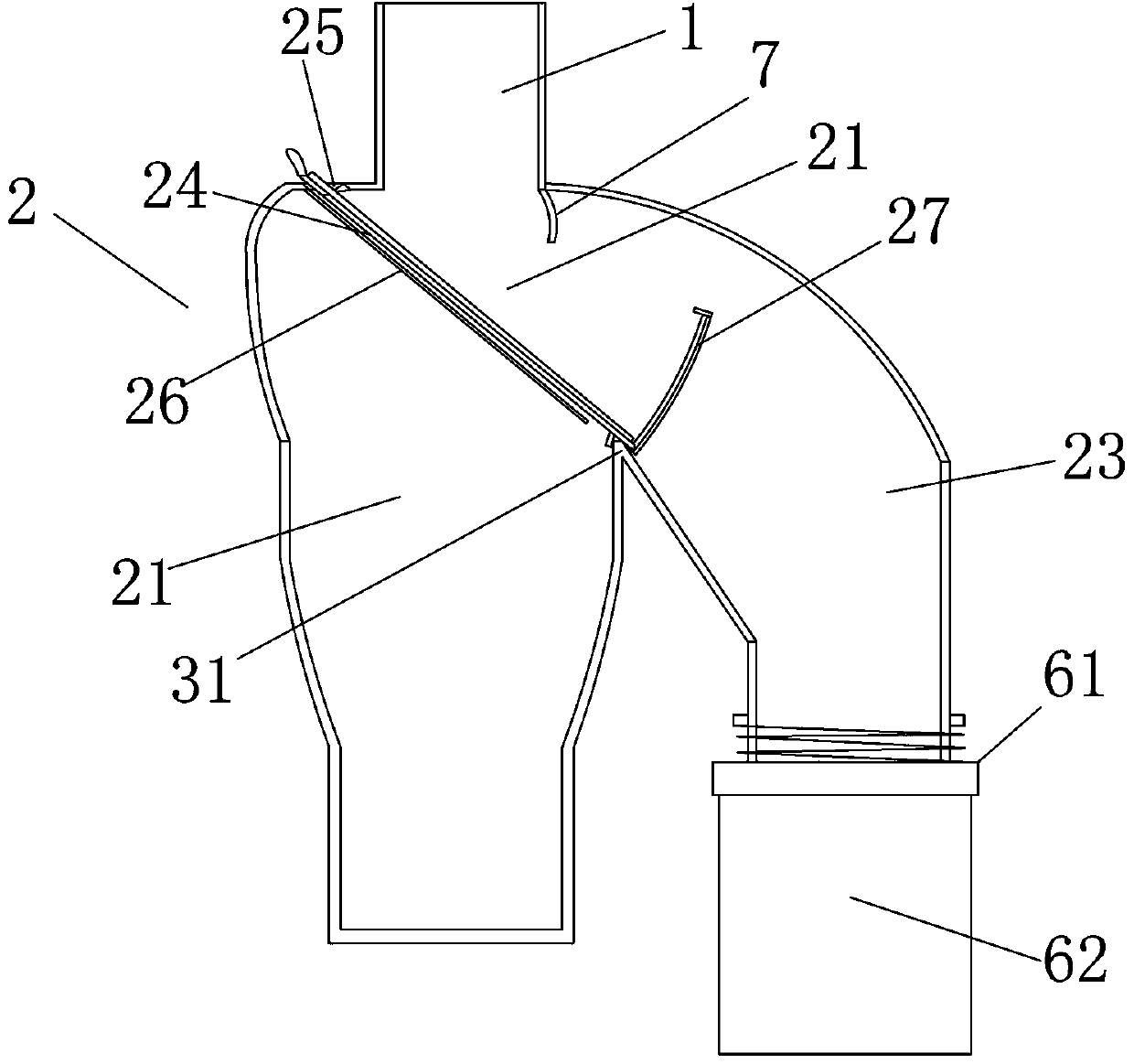

[0038] It includes an upper receiving pipe and a garbage separation mechanism connected to the lower part of the upper receiving pipe. The garbage separation mechanism includes a separation box with a separation chamber inside, a liquid outlet and a The slag outlet, the filtrate plate that is arranged in the separation chamber and is located between the upper receiving pipe and the liquid outlet and can move along the inner wall of the separation chamber, the filtrate plate is arranged directly below the upper receiving pipe, and the The liquid outlet is arranged below the filtrate plate, and the filtrate plate is an inclined plate whose lowest end is arranged on the mouth edge of the liquid outlet near the side of the slag outlet, and the top of the separation box corresponds to the filtrate There are strip-shaped perforations on the upper end of the plate, and the strip-shaped perforations are pierced through the top of the filtrate plate, and the mouth edge of the bottom of ...

Embodiment 2

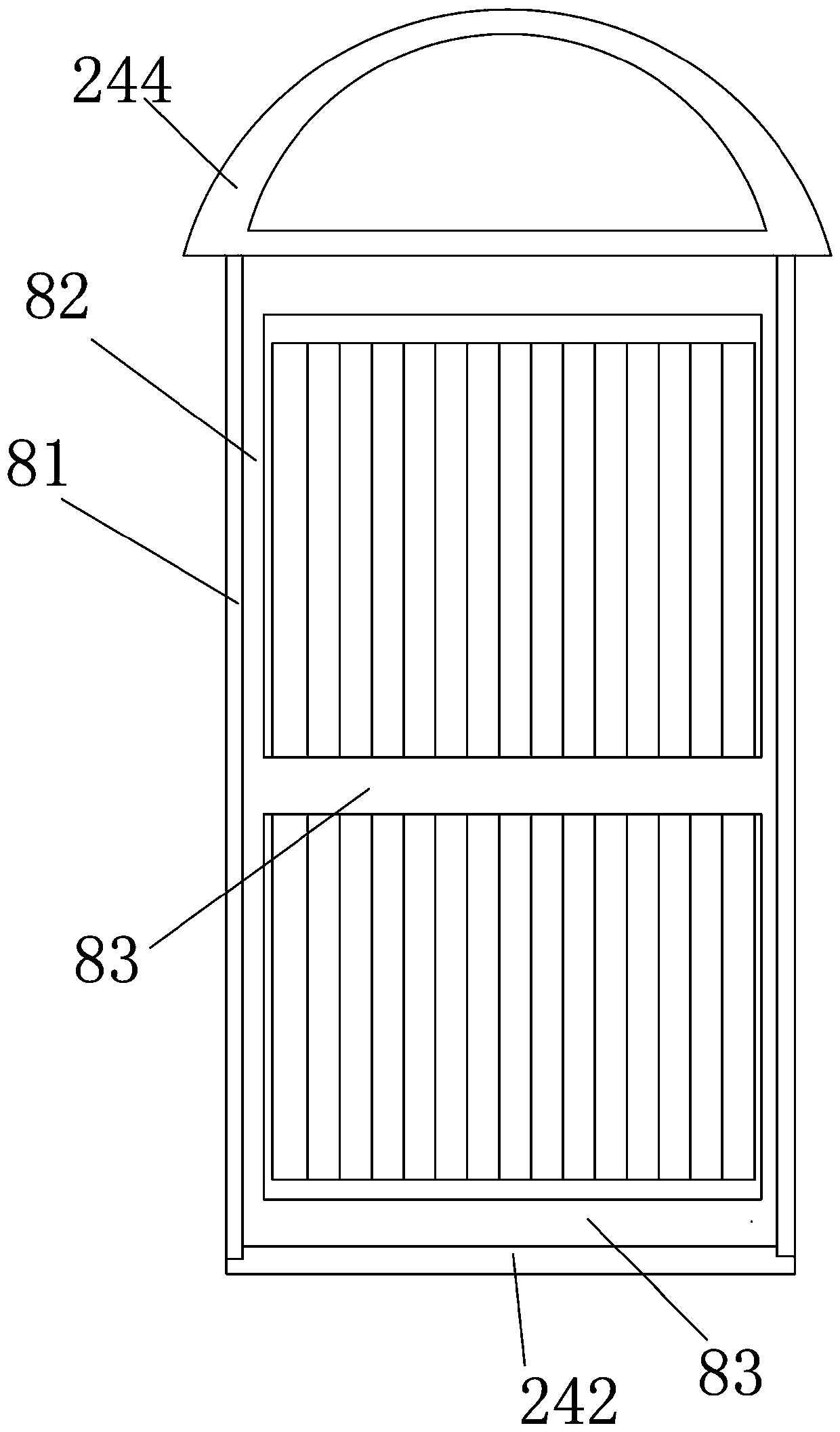

[0041] The difference from the above embodiment is that the filtrate plate is a square plate, and the side solid plate portion 241 and the bottom solid plate portion 242 are integrally connected to the two sides and the lower edge of the filtrate plate, and the side solid plate portion is close to the On the guide rail frame bar, the part close to the liquid outlet and the slag outlet is connected by a top partition or an acute-angled corner plate 31, and the bottom solid plate extends downwards and forwards across the partition Or bend the corner plate into the slag outlet.

Embodiment 3

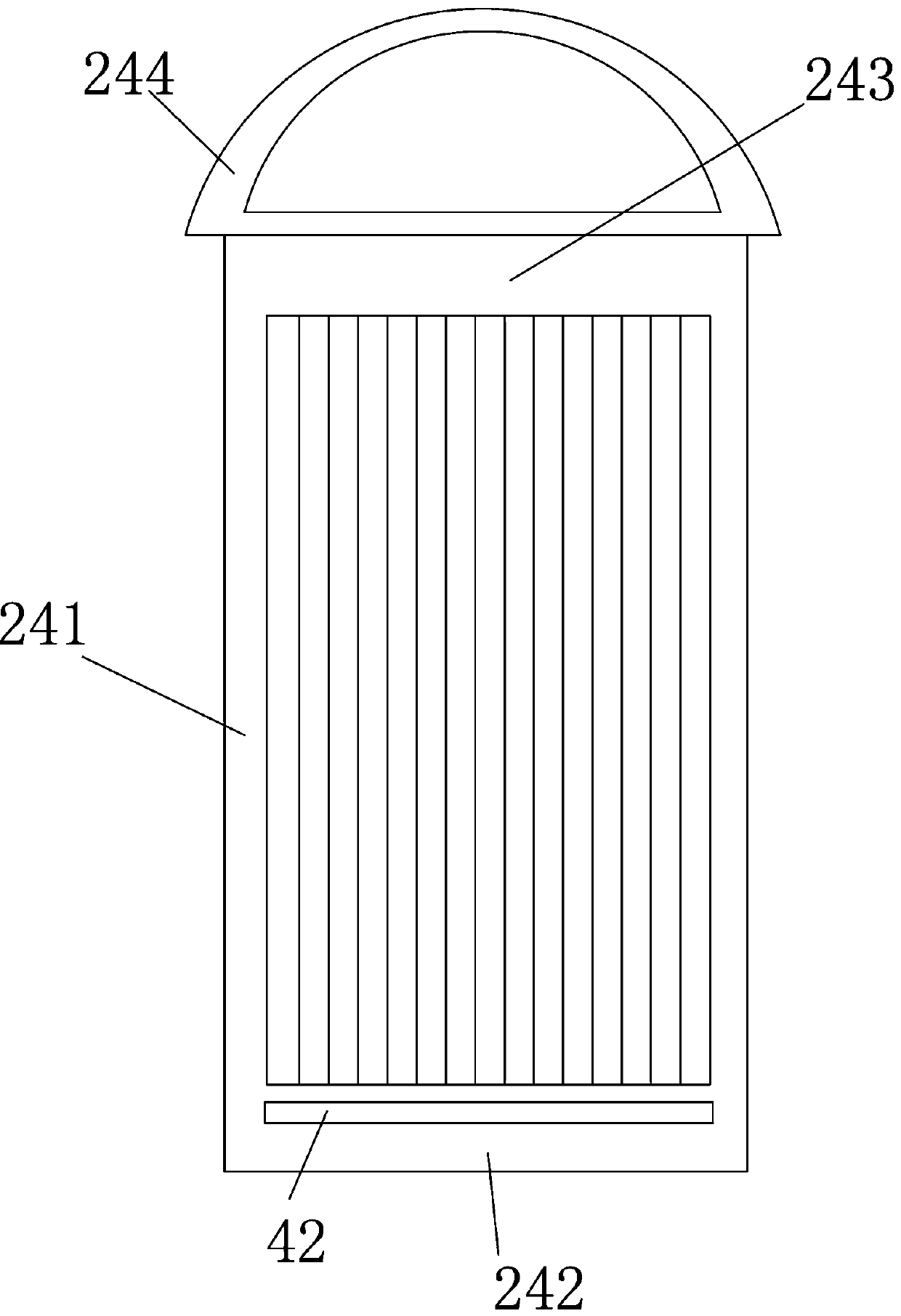

[0043] The difference from the above embodiment is that the lower surface of the bottom solid plate part is provided with a water retaining plate 42 that cooperates with the bottom surface of the bottom solid plate part to form a limit on the upper limit groove 41 of the partition plate or the angled plate part. After the water passes through the filter plate, a small part flows to the bottom surface of the filter plate, and then the water flowing towards the slag outlet is blocked by the water retaining clamp and flows into the liquid outlet instead of flowing into the slag outlet. The setting of the bottom solid plate can ensure that the residual slag is smoothly introduced into the slag outlet.

[0044] The length of the water retaining clip is smaller than the length of the bottom solid plate portion, and the distance between both ends and the wall of the separation chamber is greater than the width of the guide rail frame. The structure of the above-mentioned water-retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com