Whole angle adjusting mechanism of seat

An angle adjustment and seat technology, applied in the direction of seat arrangement, etc., can solve the problems of the driver's seat strength requiring strict dynamic impact performance and small cockpit space, and achieve easy promotion and use, high reliability, and guarantee. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

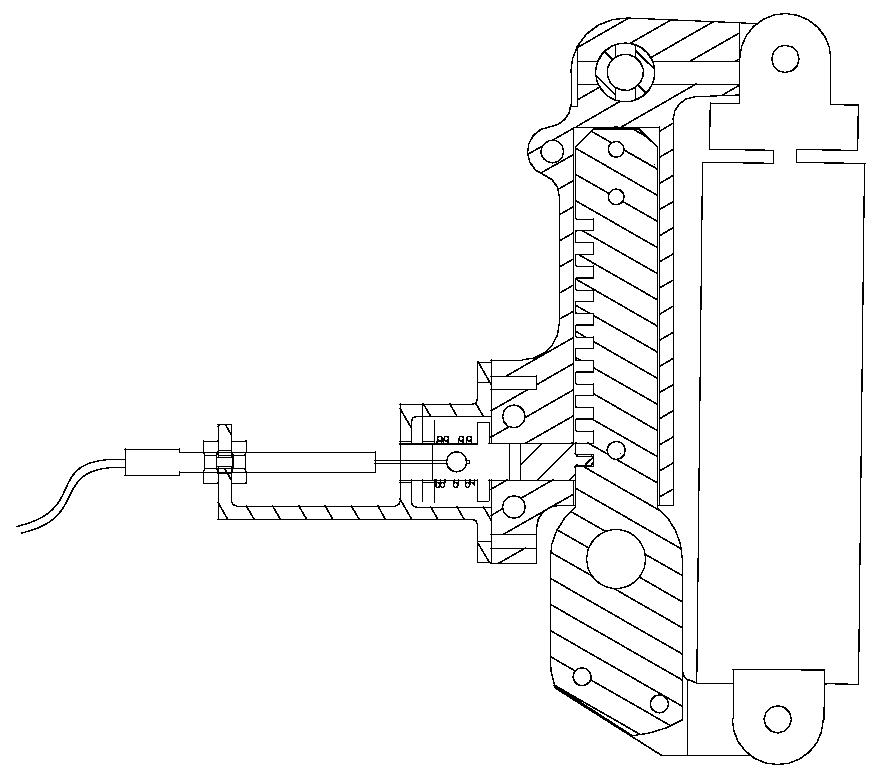

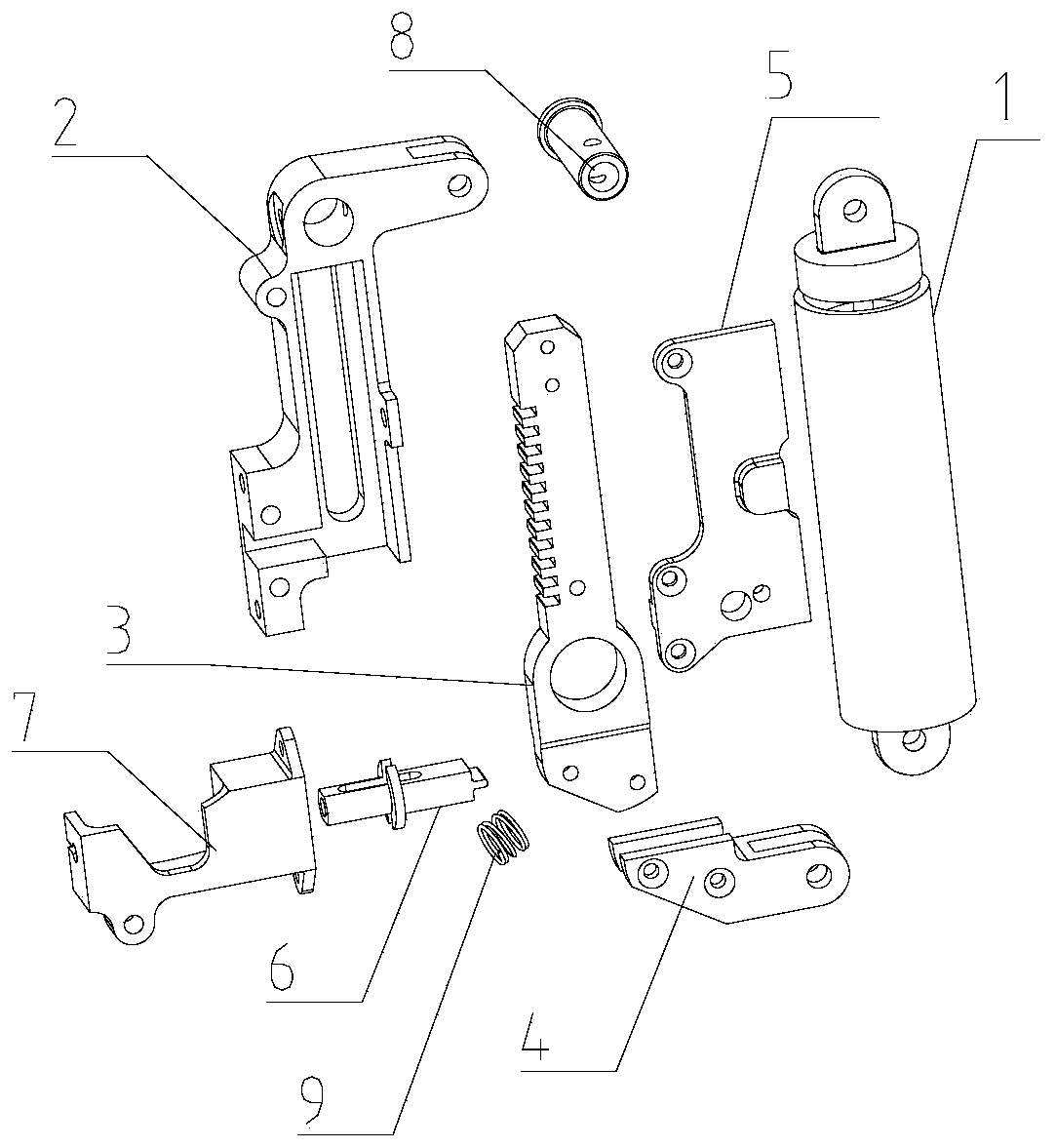

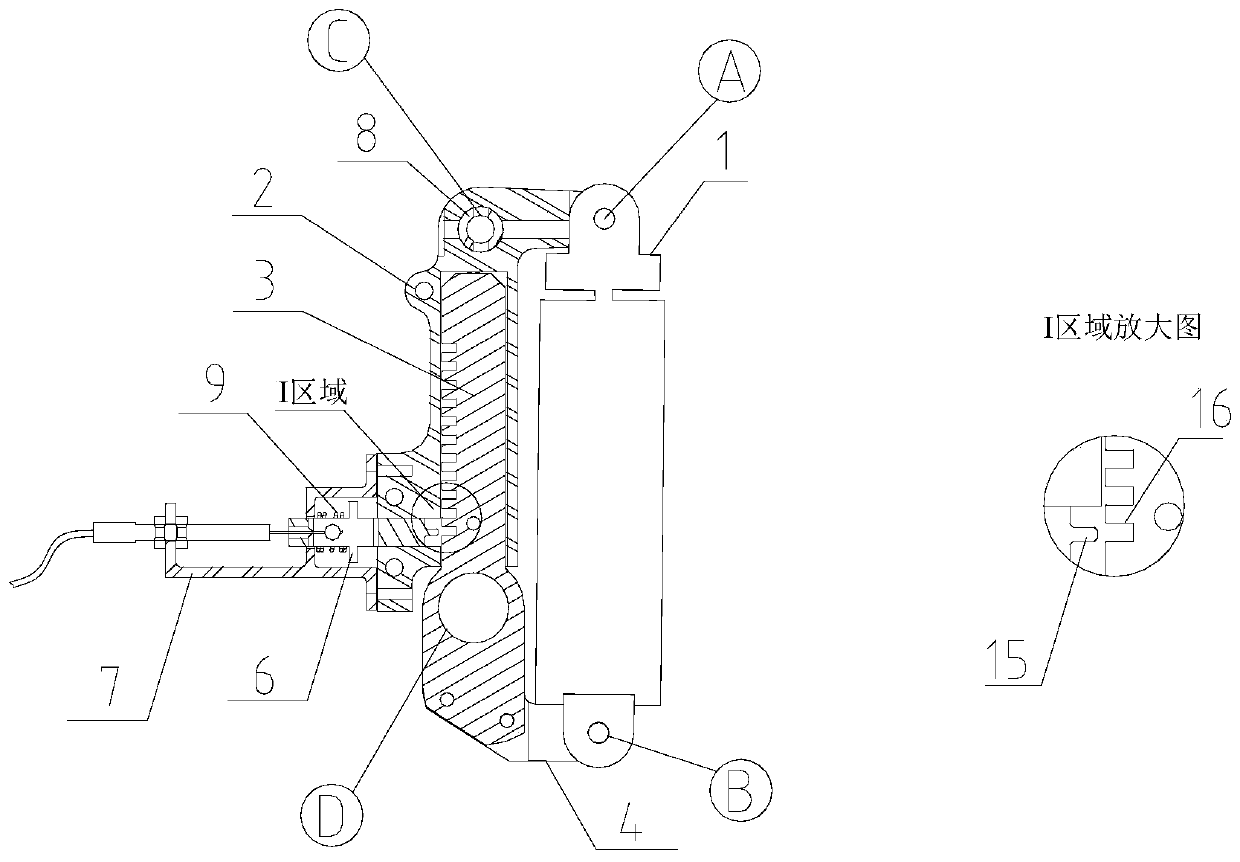

[0022] A seat angle adjustment mechanism, including a gas spring 1, a lifting mechanism 10, a base 11, a seat frame assembly 12, a backrest assembly 13, and a headrest assembly 14. It is characterized in that the lifting mechanism 10 includes an upper connecting plate 2, a locking Tooth plate 3, lower connecting plate 4, decoration 5, locking pin 6, base 7, bushing 8, spring 9, pin tooth 15 and tooth groove 16, the rear upper end of the base 11 and the rear lower end of the seat frame assembly 12 pass through E The shaft is connected and can rotate along the E axis, the front upper end of the base 11 is connected to one end of the lower connecting plate 4 through the D axis, and the front lower end of the seat frame assembly 12 is connected to one end of the upper connecting plate 2 through the C axis;

[0023] The gas spring 1 and the lifting mechanism 10 are placed in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com