A method of making imitation heat-pressed three-dimensional fabric

A production method and technology of three-dimensional fabrics, which are applied in heating/cooling fabrics, fabric surface trimming, knitting, etc., can solve the problems of rough hand feel, narrow adaptability, poor product quality, etc., and achieve obvious three-dimensional effect, wide application range, Good quality product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

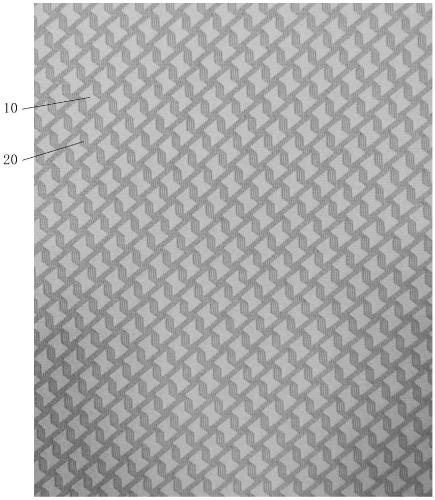

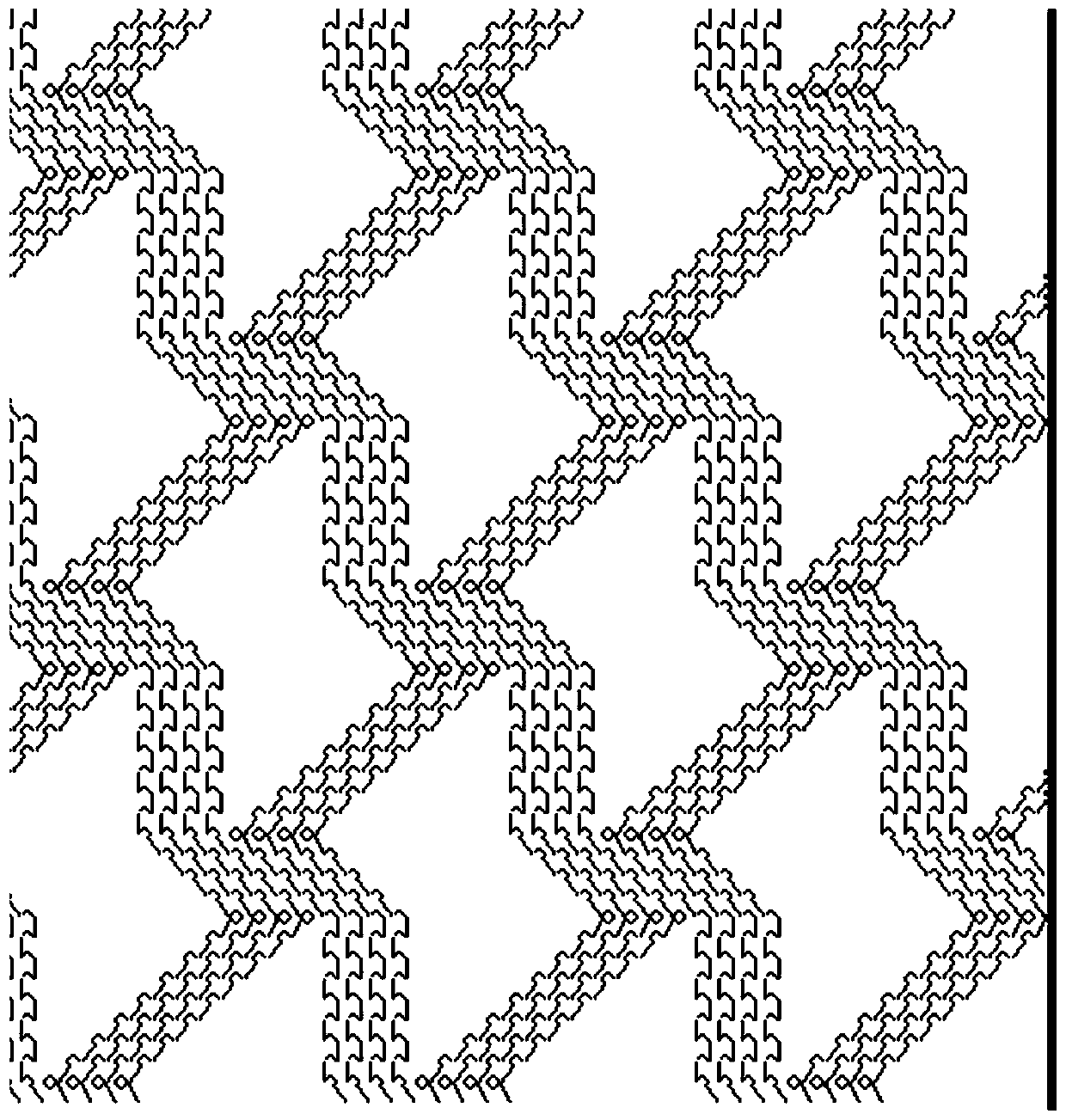

[0024] This embodiment provides a method for making imitated hot-pressed three-dimensional fabrics. The fabric obtained by this method has a three-dimensional effect similar to that after 3D ultrasonic hot-pressing treatment. figure 1 Described fabric is described in order to imitate the manufacture method of heat-pressed three-dimensional fabric, and this manufacture method comprises the following steps:

[0025] S1, weaving preparation, design the jacquard pattern of the fabric on the computer, the specific jacquard pattern can be designed according to actual needs, such as three-dimensional shapes of animals and plants such as peonies.

[0026] S2, bar configuration, using a single-bed warp knitting machine with more than three bars for knitting, wherein the single-bed warp knitting machine includes a single-bed warp knitting Jacquard machine. This embodiment selects a single-needle bed warp knitting machine with four comb bars, and each bar is arranged sequentially on the ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 lies in the jacquard pattern. The jacquard pattern of Embodiment 1 makes the uncompacted plush form a geometric figure, while in this embodiment, the jacquard pattern makes the uncompacted plush Plush forms Christmas tree shape.

[0036] Specifically, in step 3 of this embodiment, the yarn threading mode, laying structure and warp let-off amount of GB3 and GB3 are different from those of Embodiment 1. In this embodiment, GB3 is 2 threads, 1 empty, 2 threads, and 15 empty. threading in the same way, and the lapping weave of GB3 is a changing satin weave 1-0 / 0-0 / 0-1 / 1-1 / 1-2 / 2-2 / 2-1 / 1-1 / 2- 3 / 3-3 / 3-2 / 2-2 / 3-4 / 4-4 / 4-3 / 3-3 / 4-5 / 5-5 / 5-4 / 4-4 / 5-6 / 6-6 / 6-5 / 5-5 / 6-7 / 7-7 / 7-6 / 6-6 / 7-8 / 7-7 / 6-5 / 3-3 / / , the let-off amount 1700mm / lack; GB4 is threaded in the way of 2 threads, 1 hole, 2 threads and 15 holes, and the lapping weave of GB4 is a changing satin weave 3-4 / 4-4 / 3-2 / 2-2 / 2 -3 / 3-3 / 2-1 / 1-1 / 1-2 / 2-2 / 1-0 / 1-1 / 2-3 / 5-5 / 7-8 / 8-8 / 8-7 / 7-...

Embodiment 3

[0038] The difference between this embodiment and embodiment one is that the elasticity of the obtained fabric is different. The yarn used in the GB1 threading of embodiment two is polyester semi-gloss low-elastic light mesh yarn, so that the fabric elasticity is relatively small, and in In this embodiment, the yarn used for threading GB1 is 75D spandex semi-gloss yarn, the fabric obtained after weaving has relatively good elasticity, and the shrinkage of plush during dyeing and setting is more obvious, and the obtained three-dimensional effect is also better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com