A universal speed reduction device for incoming vehicles

A deceleration device and universal technology, applied in the directions of roads, buildings, road signs, etc., can solve the problems that the deceleration belt cannot achieve the speed limit effect and the effect is difficult to produce.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

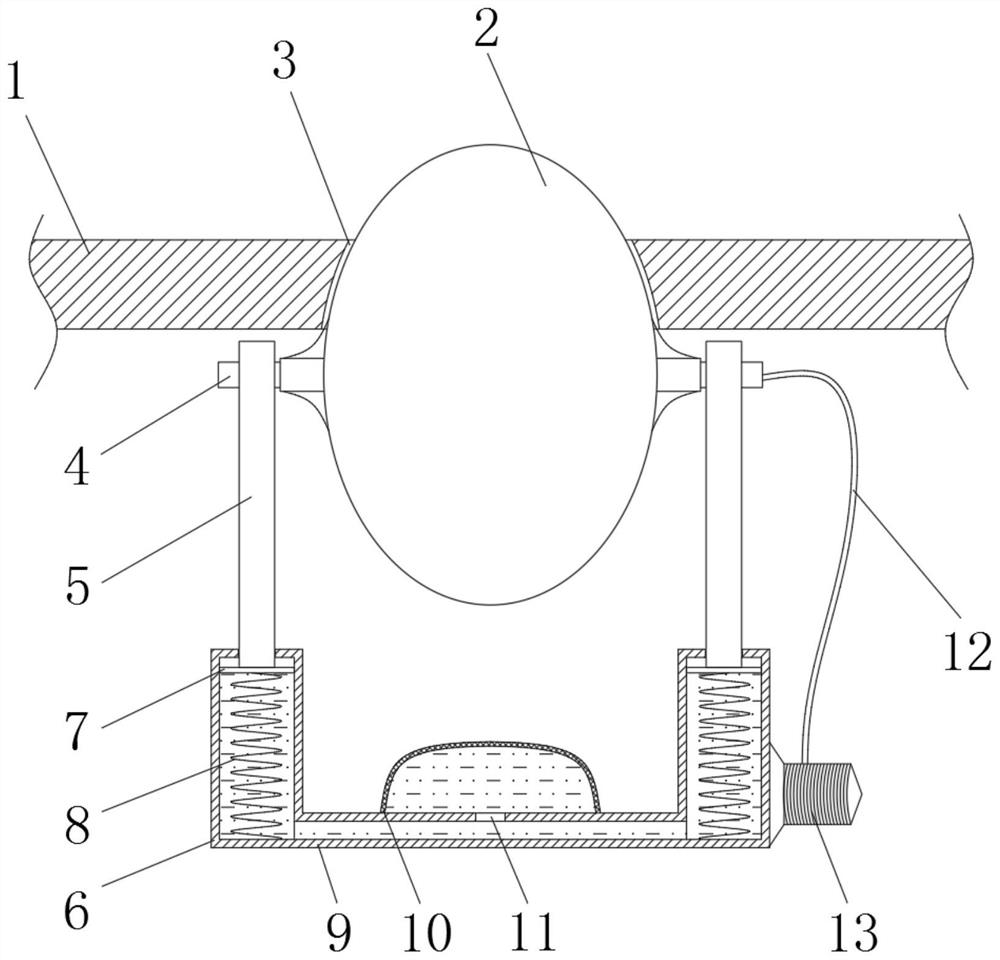

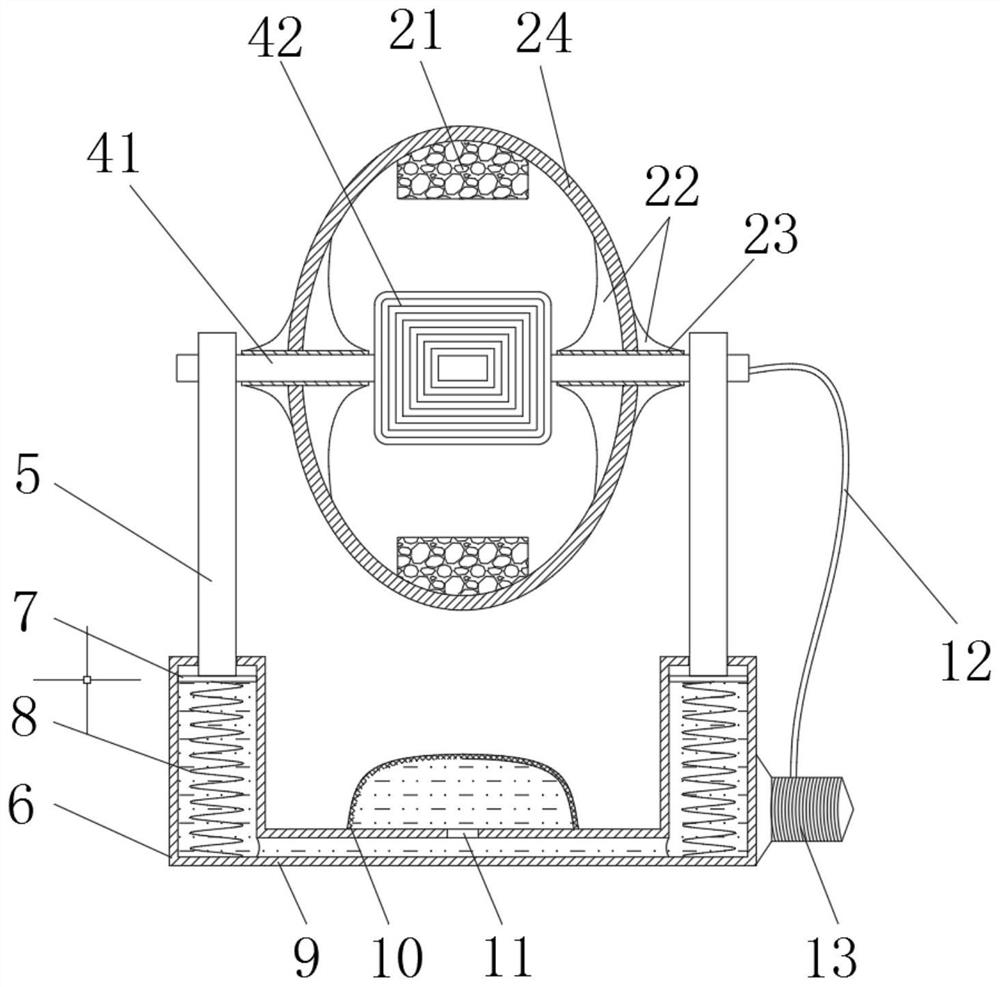

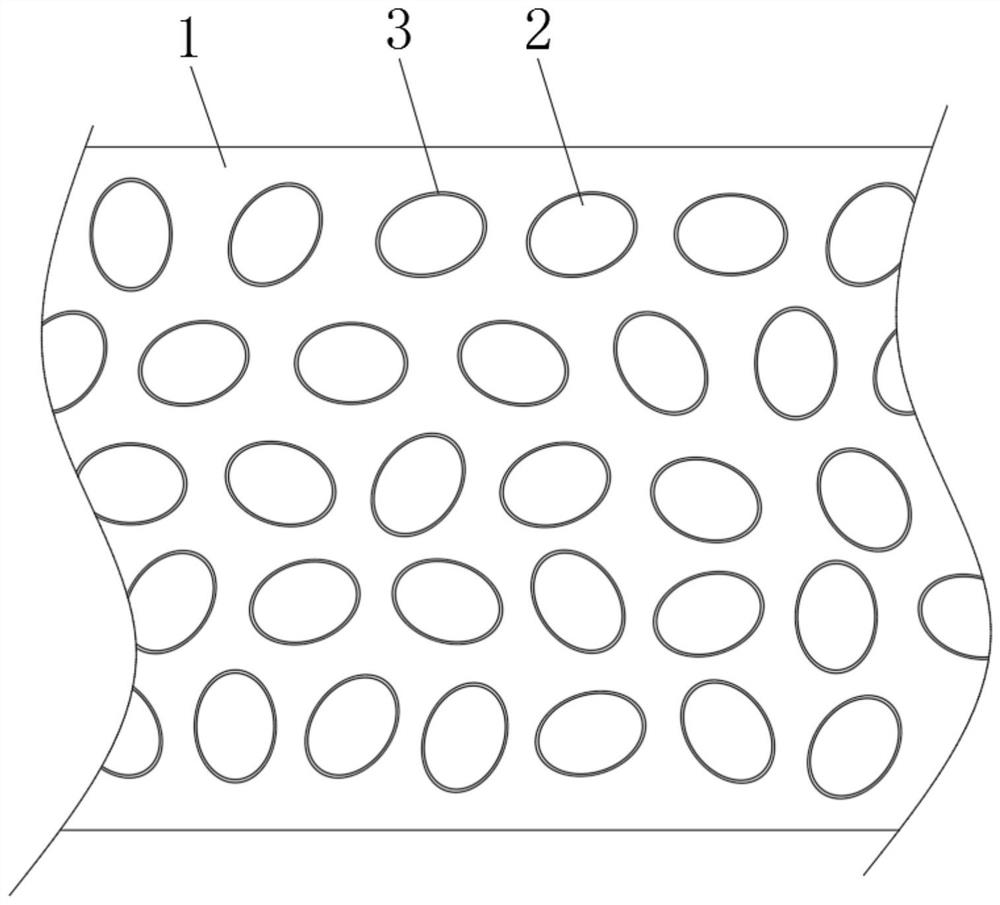

[0023] refer to Figure 1-4 , a universal oncoming vehicle deceleration device, including a floor 1 and a rotating ball 2, the floor 1 is provided with a plurality of ball holes 3, when the rotating ball 2 is at the highest point, the ball holes 3 are not in contact with the rotating ball 2, and every two There is a certain distance between two adjacent ball holes 3 to ensure that the floor between the two ball holes 3 produces enough reaction force to the wheels when the vehicle is running at a slow speed. Each ball hole 3 is provided with a The rotating ball 2 is connected to the stator 4 through a bearing, and a vertical rod 5 is fixedly connected to both ends of the stator 4, and a round tube 6 is arranged at the lower end of each vertical rod 5, and the inside of each round tube 6 There is a piston 7 in the sealing and sliding connection, and a spring 8 is fixedly connected to the lower end of each piston 7. When the vehicle passes by the rotating ball 2, the spring 8 wil...

Embodiment 2

[0034] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that a plurality of ball grooves 25 are uniformly arranged on both sides of the outer wall reinforcement plate 22 of the ellipsoidal shell 24, and a steel ball 26 is rotatably connected in each ball groove 25, and the ball 26 It cannot fall off from the ball groove 25. When the tire of the vehicle is laterally pressed to the rotating ball 2, it can effectively reduce the torque on the rotating ball 2 and the stator 4, and reduce the possibility of damage to the rotating ball 2 and the stator 4, greatly The service life of the road section provided with the device is prolonged.

[0035] Although this article uses more floor 1, rotating ball 2, ball hole 3, stator 4, vertical rod 5, round tube 6, piston 7, spring 8, horizontal tube 9, liquid storage bag 10, through hole 11, wire 12 , Electromagnet 13, permanent magnet 21, reinforcing plate 22, through mandrel 23, ellipsoid shell 24, ball groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com