Preparation device for quantitative detection of dangerous gas, and configuration method of preparation device

A quantitative detection and dangerous gas technology, which is applied in the field of preparation devices for quantitative detection of dangerous gases, can solve the problems of difficult sampling, difficult acquisition, and high price, and achieve the effect of simple and easy sampling operation, accurate and reliable quantification, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

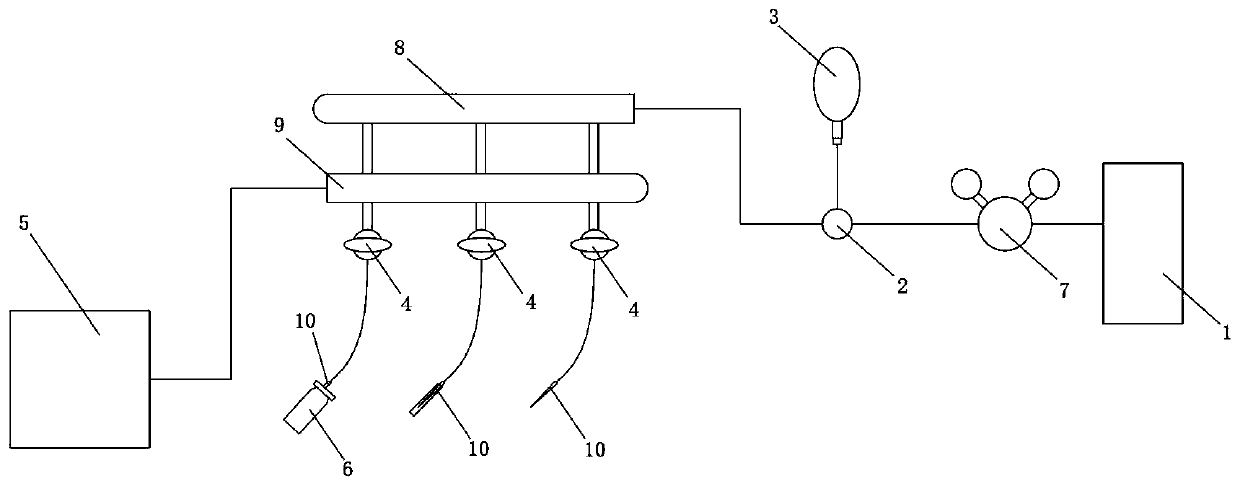

[0033] See Figure 1 to Figure 3 , the preparation device for the quantitative detection of hazardous gases in this embodiment includes a storage tank 1 for the gas to be tested, a three-way valve 2, a balloon 3, a glass valve 4, a vacuum pump 5 and a packaging container 6.

[0034] The three-way valve 2 is used to connect the deflation port of the gas storage tank 1 to be tested and the balloon 3 or the balloon 3 and the glass valve 4 . The glass valve 4 is used to communicate the vacuum pump 5 with the subpackage container 6 or the three-way valve 2 with the subpackage container 6 . A decompression valve 7 is provided on the gas pipe connecting the gas storage tank 1 to be tested and the three-way valve 2 . The three-way valve 2 adopts the existing three-way valve at present.

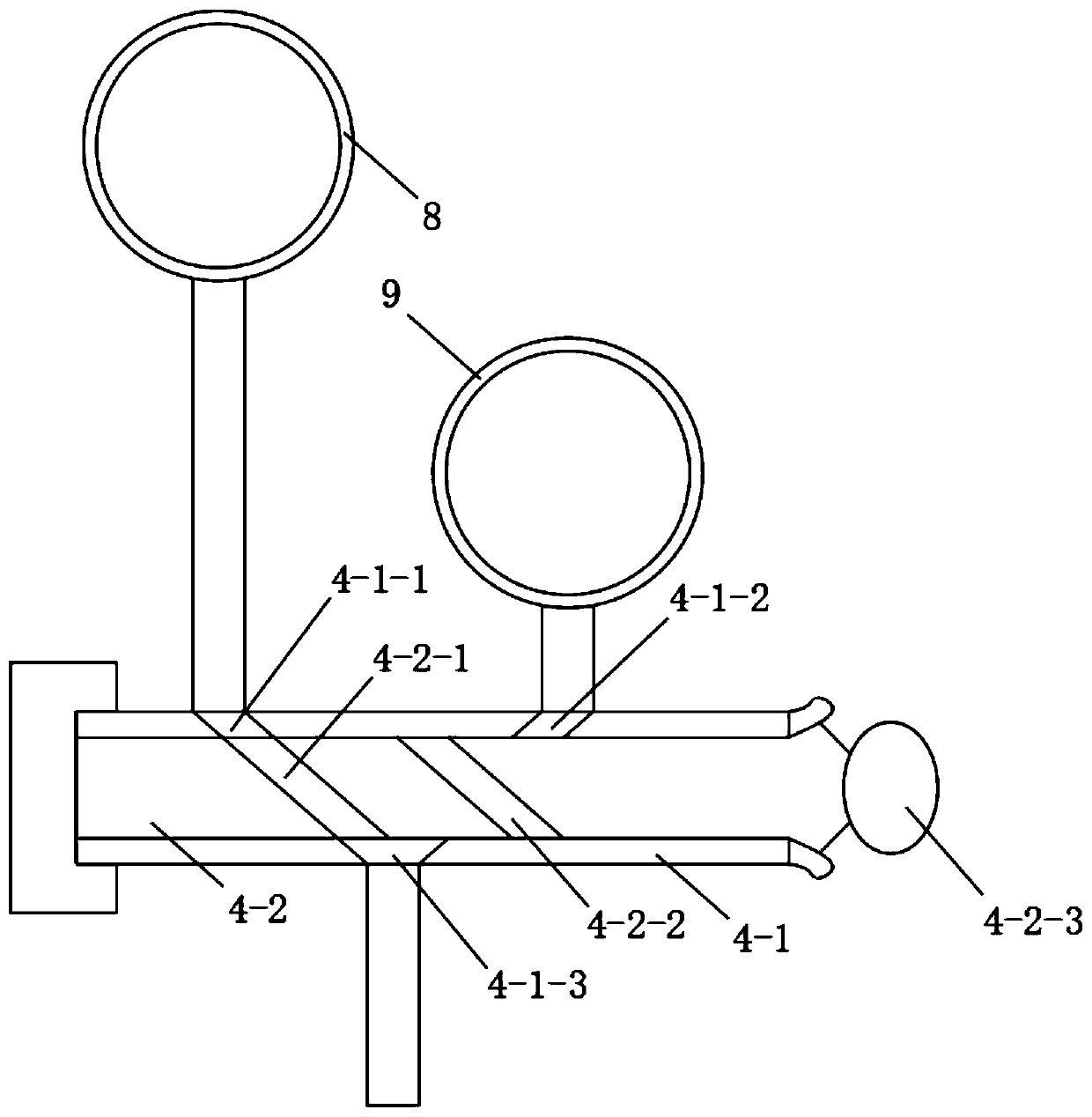

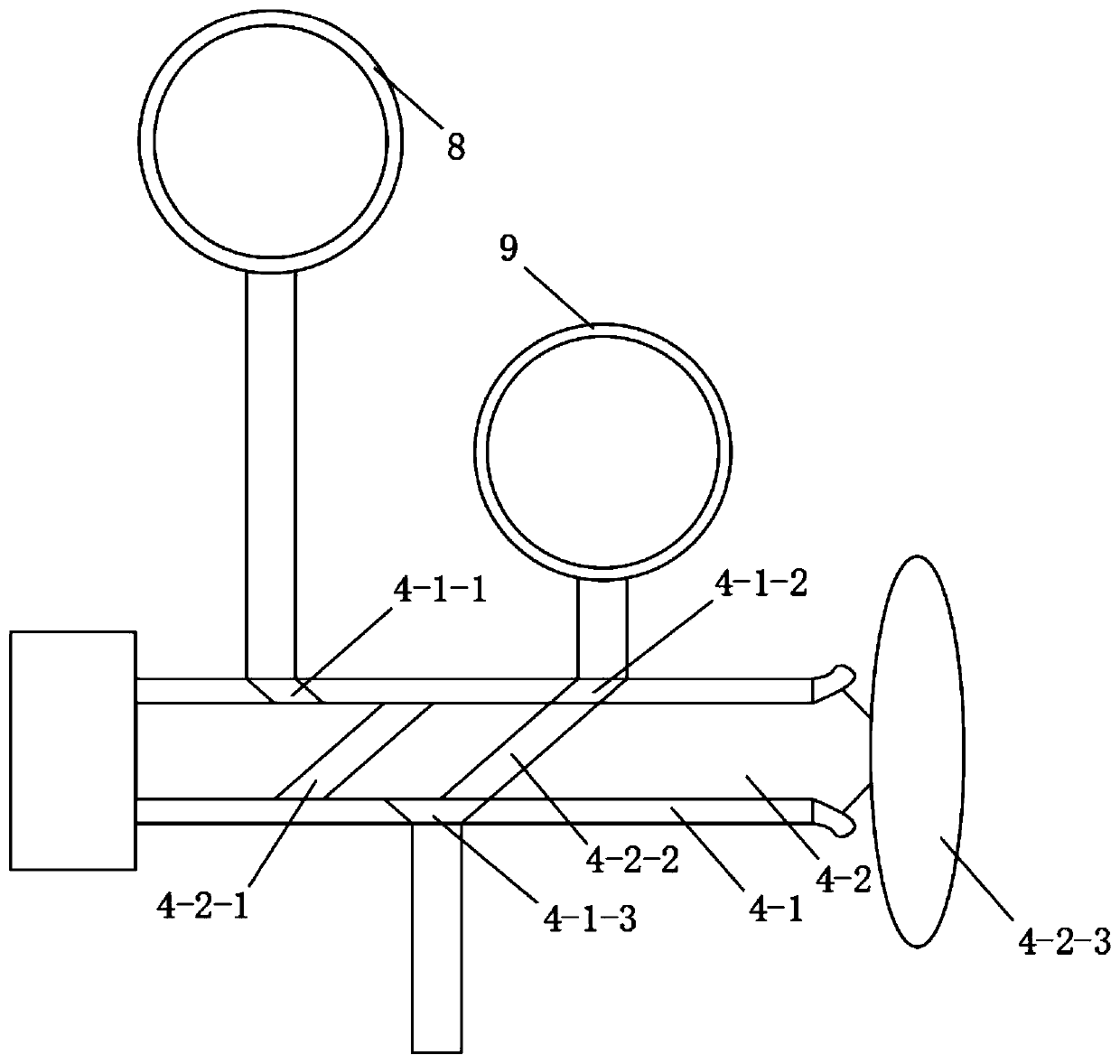

[0035] The glass valve 4 includes a valve housing 4-1 and a valve core 4-2. The valve housing 4-1 is provided with a first port 4-1-1, a second port 4-1-2 and a third port 4-1-3. The first port 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com