Quantitative compost sampling device and sampling method thereof

A sampler and composting technology, applied in the field of quantitative compost sampler and its sampling, can solve the problems of inability to realize multi-point and small-scale mixed sampling, inconvenient sampling process of fecal compost body, poor flexibility of fixed-depth quantitative sampling, etc., and achieve production cost. Low cost, accurate sampling, high efficiency, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

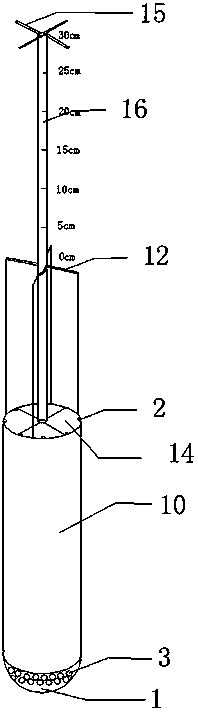

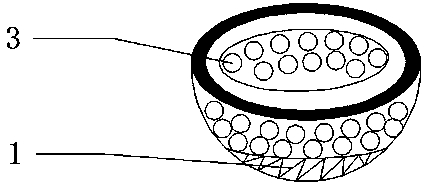

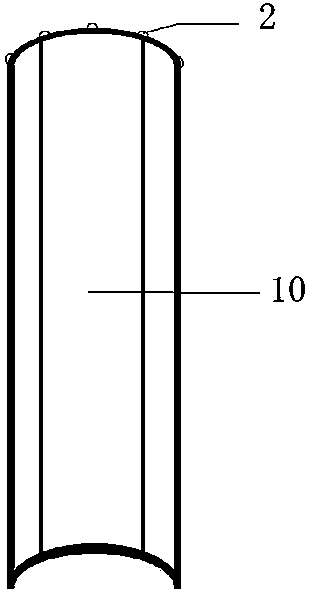

[0031] The quantitative composting sampler includes an ellipsoidal drill bit 1, a closable screw device 5, a first movable connecting rod device 8, a sample collection tube 10, a closeable agitator 11 with a scale, and a second movable connecting rod device 13;

[0032] The ellipsoidal drill bit 1 is provided with a sampling hole 3, and the closable screw device 5 includes a support rod 6 and four first blades 7, and the four first blades 7 are each provided with a square hole in the lower right corner. 9. The first movable connecting rod device 8 includes a first control handle 12, four connecting rods and four first loop hooks 4, and the four first loop hooks 4 respectively pass through the four connecting rods and the first control handle 12 is connected to the outer edge, the four first loop hooks 4 of the first movable link device 8 are respectively connected to the four square holes 9 of the closable screw device 5, and the first movable link device 8 is set in the sampl...

Embodiment 2

[0042] The installation process of this embodiment is the same as the above-mentioned embodiment 1. The main difference lies in the working principle: after the sampling is completed, the closable spiral device 5 is in the closed state, and the upper control handle 12 is pressed to displace the closable agitator 11 with scales. Stir the sample in the sample cylinder 10 by pushing and turning the upper control handle 12, repeat 3 times to make the sample evenly mixed, and finally restore the closeable agitator 11 with scale to the highest point 0cm scale line, and move the upper control handle Close it to complete the stirring of the sample.

Embodiment 3

[0044] The installation process of this embodiment is the same as the above-mentioned embodiment 1. The main difference lies in the working principle: After the stirring is completed, press the lower control handle of the sampler to open the closable spiral device 5, and close the closable agitator 11 with graduations by pushing. , Press the position of the movable connecting rod device 8 connected with the scaled closeable agitator 11 to achieve the purpose of quantitative sampling, and push the extruded compost sample into the sample collection bag. After the sample collection is completed, the closable screw device 5 and the scaled closable agitator 11 can be opened for flushing, and the next sampling can be continued.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com