Oil filling pipe buffer for automobile oil tank

A technology of automobile fuel tank and fuel pipe, which is applied to vehicle components, layout combined with internal combustion engine fuel supply, power plant, etc., can solve serious problems such as fuel leakage and oil leakage, achieve simple structure, avoid oil leakage, The effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with embodiment and accompanying drawing.

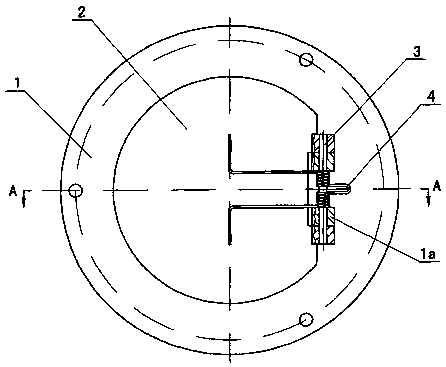

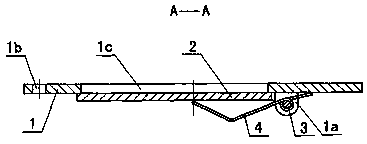

[0010] See Figure 1, Figure 2

[0011] The oil tank filling pipe buffer provided by the present invention has a base 1, and a through hole 1c is opened in the middle of the base 1. The bottom of the base 1 hinges the cover plate 2 through the pin shaft 3 in the following way: the bottom of the base 1 has a pair of bosses 1a, the bosses 1a are integrated with the base 1, the pin shaft 3 passes through the cover plate 2, and the pin shaft The two ends of 3 are fitted in the boss 1a. The pin shaft 3 is equipped with a spring 4, and the two ends of the spring 4 respectively abut against the base 1 and the cover plate 2, and under the action of the spring 4, the cover plate 2 closes the port 1c.

[0012] Referring to Figure 1, in order to facilitate the installation of the buffer in the oil tank filling pipe, there are more than two installation holes 1b uniformly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com