Deforming energy-absorbing anchor ring and anchor rod supporting method for preventing anchor rod from being broken and catapulted

A bolt support and bulletproof technology, which is applied in the installation of bolts, the measurement of the change force of the optical properties of the material when it is stressed, and the earth cube drilling and mining, etc., can solve the problems of long operation time, slowing down the excavation speed, Problems such as blindness and unpredictability can achieve the effect of preventing accidents, improving safety, and delaying premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

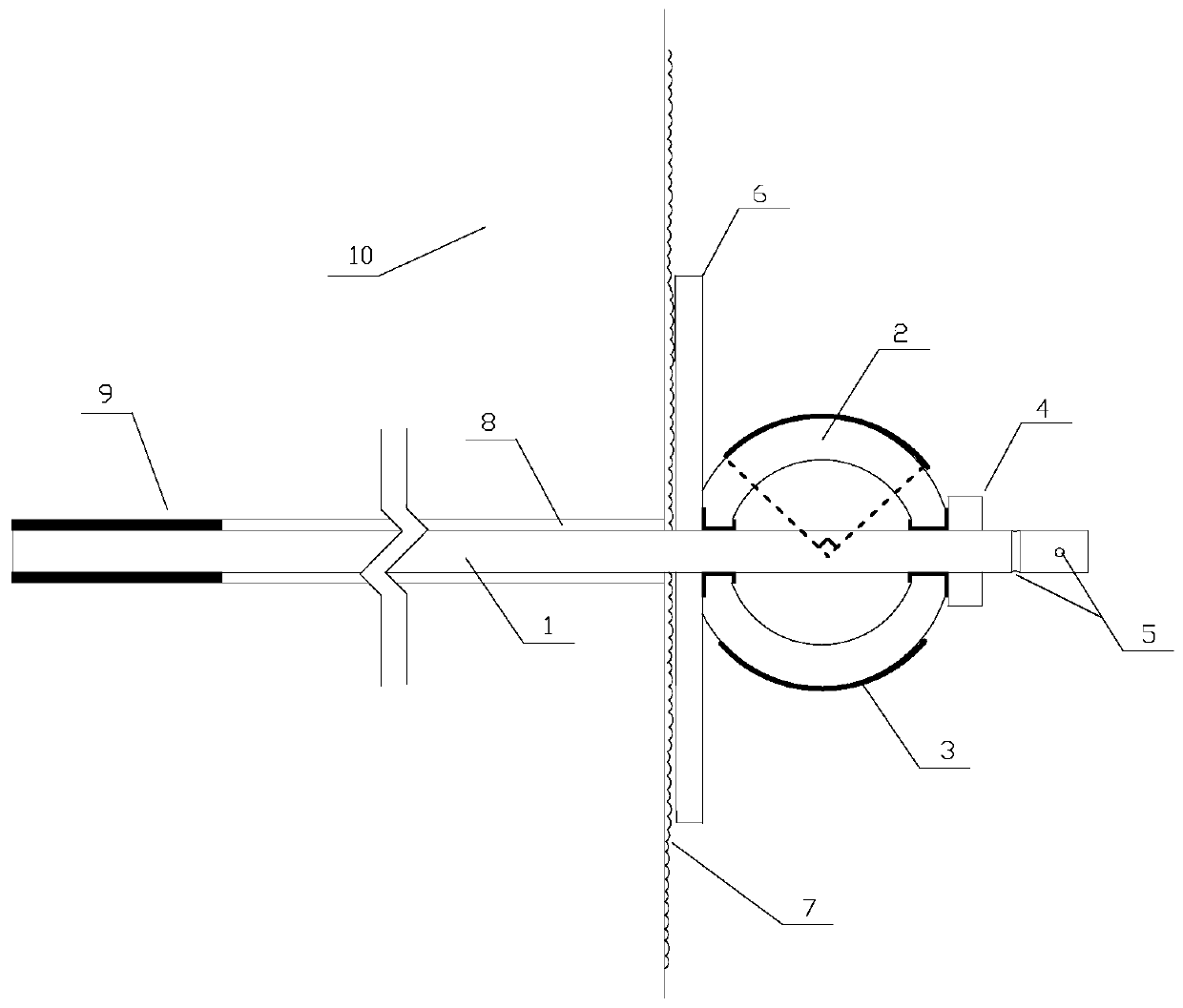

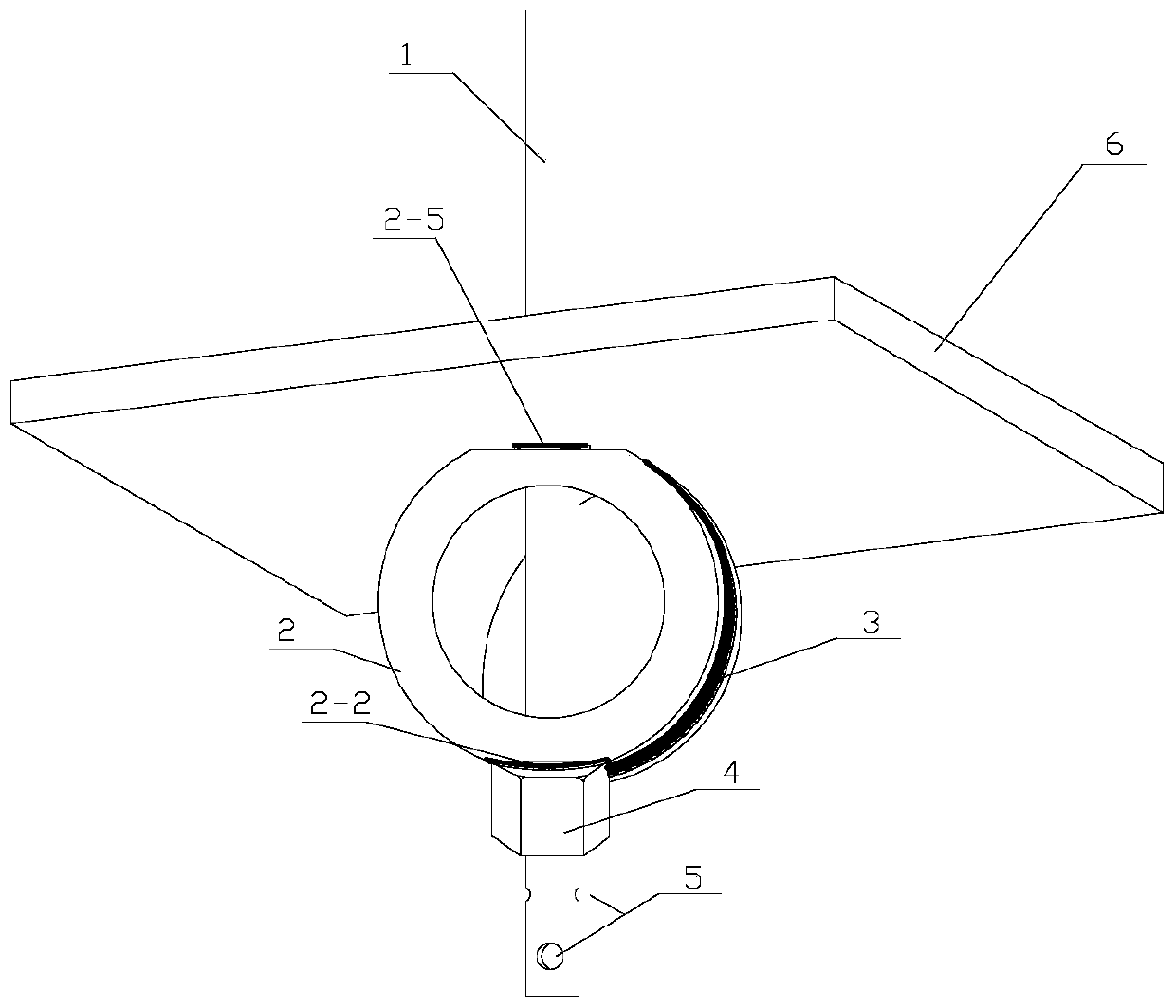

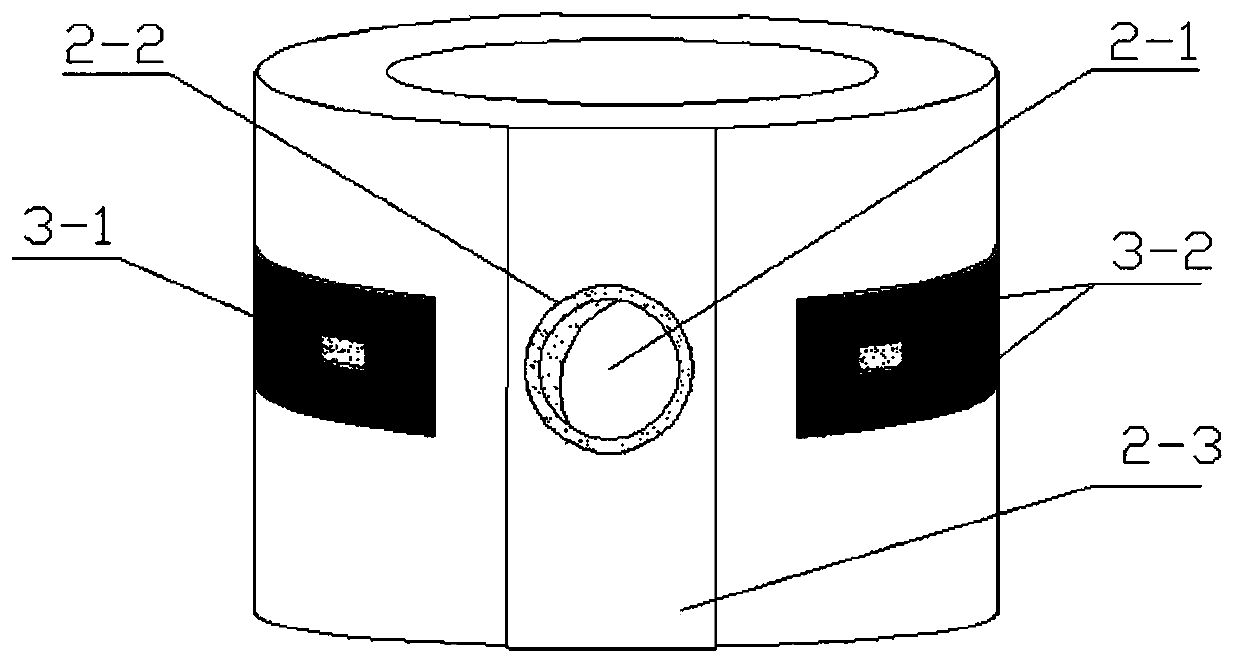

[0033] Such as figure 1As shown, the deformed energy-absorbing anchor ring of the present invention and the bolt support device for preventing the bolt from breaking and ejecting include the anchor rod 1 extending into the borehole 8 and fixed by the anchoring agent 9, and the anchor rods exposed in the hole are arranged in sequence. 1. On the barbed wire 7, the tray 6 and the nut 4, there are two openings 5 at the end of the anchor bar that are intersected in a cross shape at the tail of the anchor bar 1, and an anchor ring 2 is provided between the tray 6 and the nut 4 , the anchor ring 2 is provided with a facing hole that is sheathed on the anchor rod 1, and the contact ends of the anchor ring 2, the tray 6 and the nut 4 are planes, which are respectively the bonding surface of the nut end of the anchor ring and the tray end of the anchor ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com