Steel wire rope middle fixator and use method thereof

A technology of intermediate fixation and wire rope, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of inability to set up, cumbersome operation, labor and time-consuming, etc., and achieve the effect of convenient operation, strong safety and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

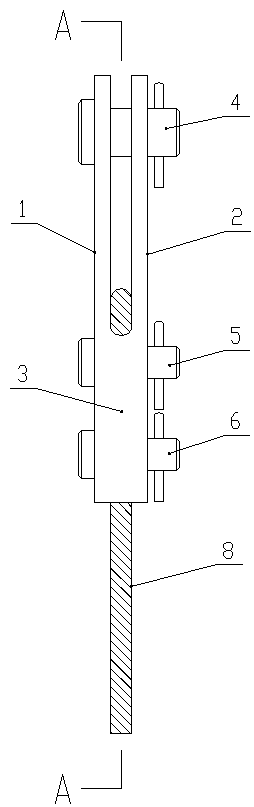

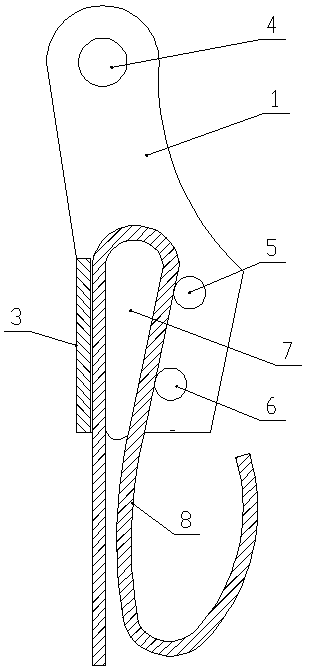

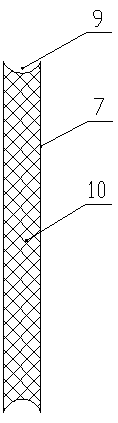

[0023] Such as Figure 1-Figure 4 As shown, the wire rope intermediate fixer of the present invention includes a left side plate 1 and a right side plate 2 arranged vertically and parallel to each other, and a vertical It is connected to the slat 3 as a whole, and the upper parts of the left side board 1 and the right side board 2 are provided with lifting eye holes correspondingly on the left and right, and the lifting ear pins 4 are pierced in the lifting eye holes, and the lower parts of the left side board 1 and the right side board 2 are in the The rear side of the vertical strip 3 is provided with two sets of positioning holes that are transparent left and right. The first positioning pin 5 and the second positioning pin 6 are respectively installed in the two groups of positioning holes. The position of the first positioning pin 5 is higher than The second positioning pin 6, the distance from the first positioning pin 5 to the left side plate 1 is greater than the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com