Fuel gas plug valve

A gas plug valve and plug valve technology are applied in the field of plug valves to achieve the effects of comfortable hand feel, prompt and obvious prompts, and reduction of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

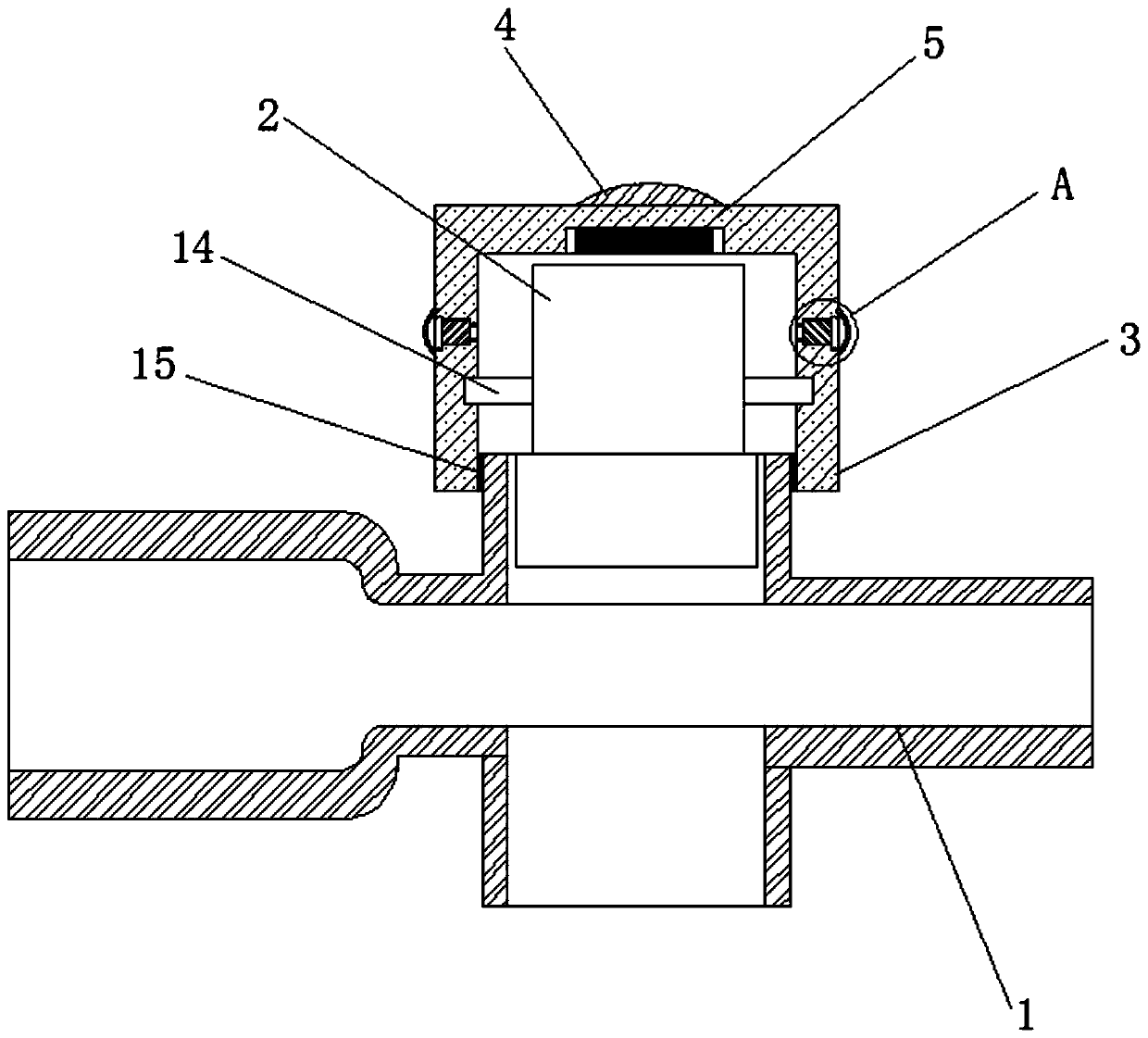

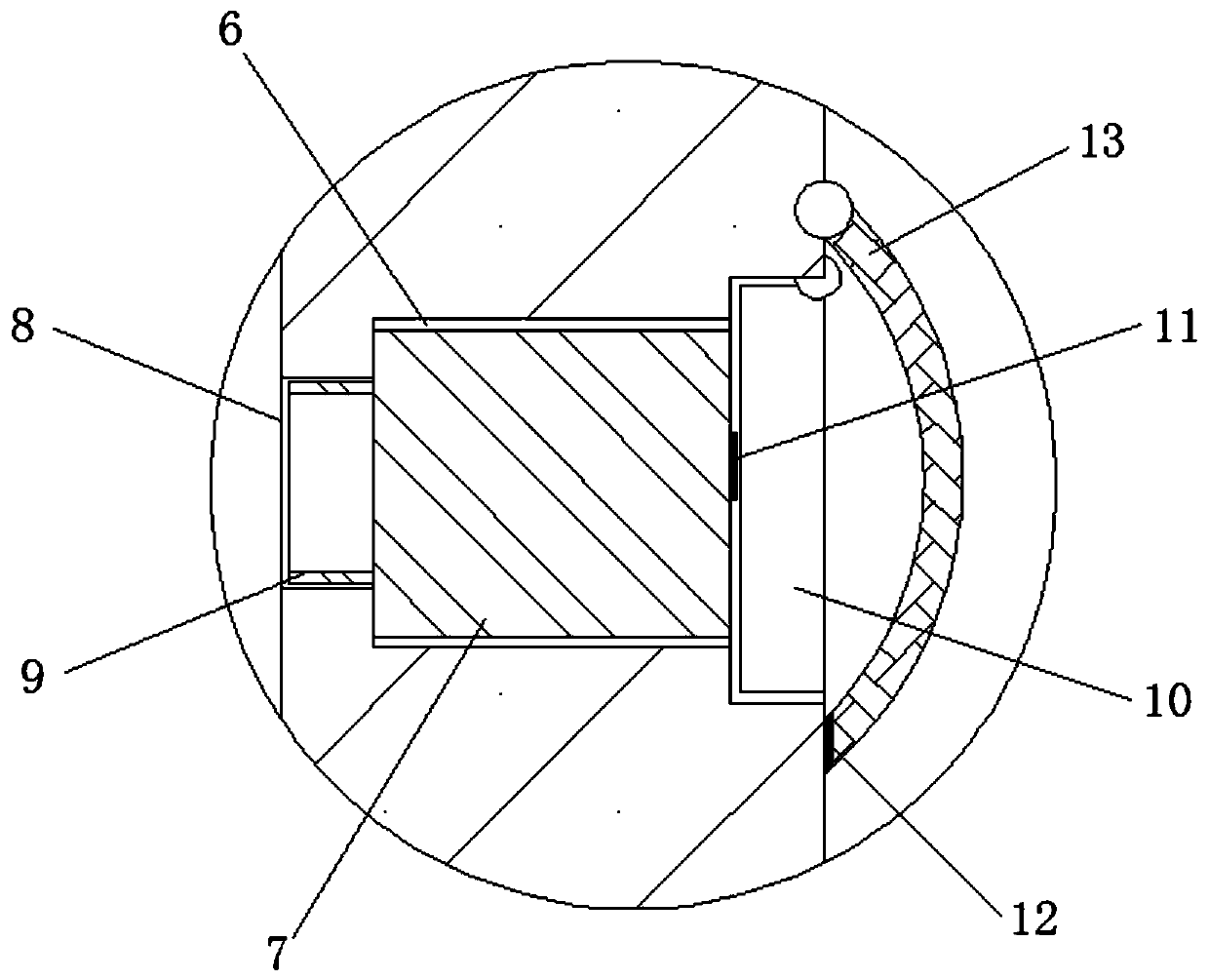

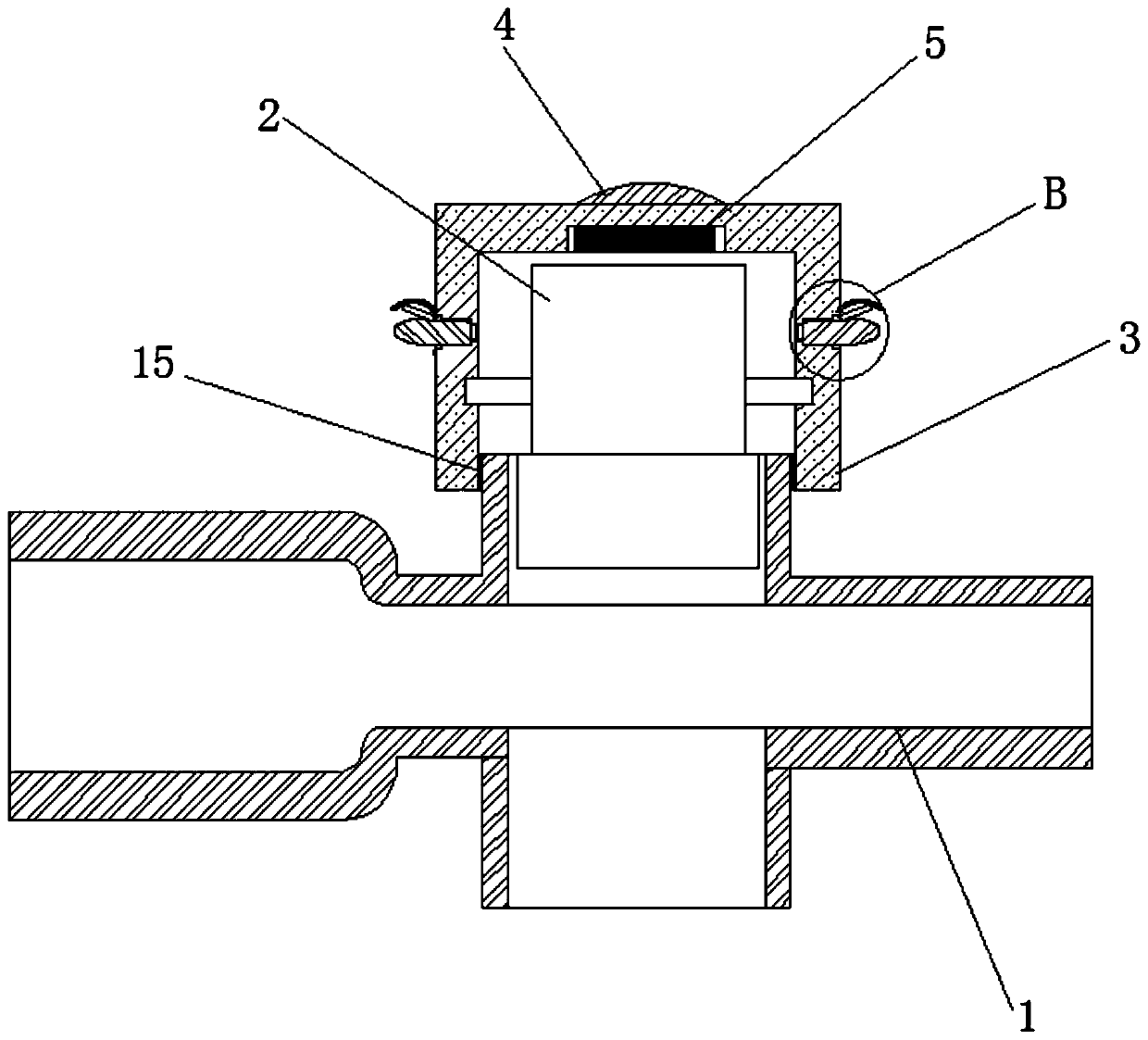

[0040] see figure 1 , a gas plug valve, comprising a plug valve body 1, the plug valve body 1 is connected with a plug rotating block 2, the plug valve body 1 is provided with a plug protective sleeve 3 on the upper side, and the plug protective sleeve 3 is matched with the plug rotating block 2, A sealing bearing 15 is fixedly connected between the upper end of the plug valve body 1 and the edge of the inner wall of the plug protection sleeve 3, and a synchronous rotation fixing rod 14 is fixedly connected between the inner wall of the plug protection sleeve 3 and the plug rotating block 2, and the inner top of the plug protection sleeve 3 is drilled and installed A gas sensor 5 is connected to the installation groove. A gas leakage warning light 4 is arranged on the outer top of the cock protection sleeve 3. The gas leakage warning light 4 and the gas sensor 5 are electrically connected through an external controller. Please refer to figure 2 A plurality of gas leakage thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com