An anti-dumping safety hydraulic support

A hydraulic support and safety technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of hydraulic support base subsidence, hydraulic support upside down, etc., and achieve better grip and anti-dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

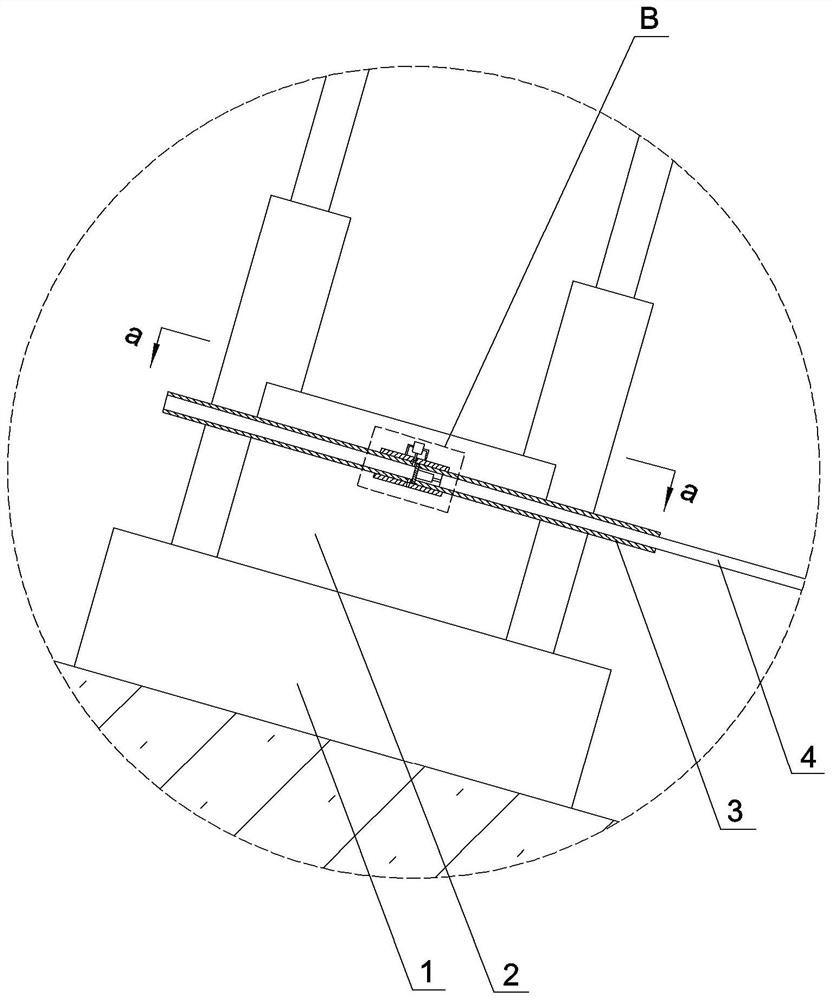

[0023] The reference signs in the drawings of the description include: bracket base 1, vertical plate 2, sliding sleeve 3, partition 30, through hole 300, insertion area 301, insertion matching area 302, insertion rod 4, bottom adjustment jack 5, rotating sleeve 6. Rotating shaft 60, locking hydraulic cylinder 7, switching motor 8.

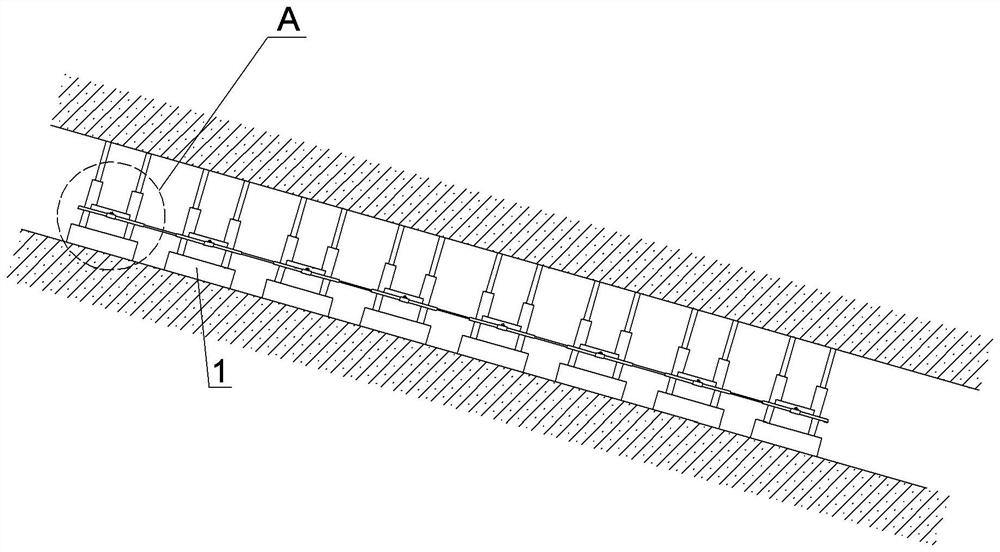

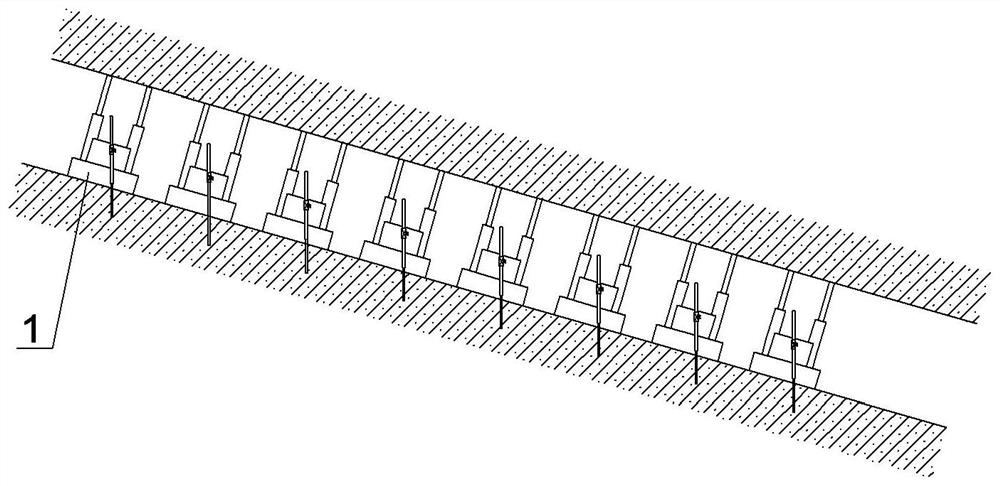

[0024] Such as figure 1 and figure 2 As shown, the anti-dumping safety hydraulic support in this embodiment includes a bottom adjustment mechanism arranged on the base 1 of the support. combine image 3 , Figure 4 and Figure 5 As shown, the bottom adjustment mechanism includes a vertical plate 2 welded to the front and rear ends of the support base 1 and a rotating shaft 60 pierced on the vertical plate 2; 60 welding, the outer end of the rotating shaft 60 is welded with a rotating sleeve 6, the sliding sleeve 3 is slidably connected in the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com