Glue dispensing filling applying process of full display screen, full display screen and electronic equipment

A full-screen and glue-dispensing technology, which is applied to devices, optics, instruments, etc. for coating liquid on the surface, can solve problems such as the inability to achieve a full screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

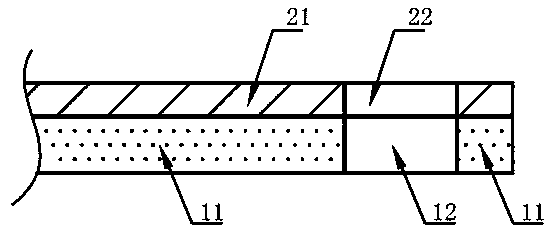

[0067] like Figure 8 As shown in , a partial schematic diagram of an electronic device provided by an embodiment of the present invention includes a camera and a full screen as described in Embodiment 1. The camera is set under the full screen, and the position of the camera is facing the perspective hole. After passing through the cover plate 30 , the light can enter the camera through the through hole 22 of the polarizer 21 and the light-transmitting area of the display screen 10 , so that the camera can work normally. Since it is avoided to divide the area outside the display interface area of the display screen 10 to set up the camera, the display interface of the electronic device is completely covered by the screen, thereby achieving a true full screen.

[0068] The electronic device may be a mobile phone, a computer, or a wearable device.

[0069] Compared with the prior art, the beneficial effects of the present invention are as follows:

[0070] 1. The displa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure shrinkage | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com