Safety belt braking method based on shear thickening fluid drive, and safety belt brake

A technology of thickening liquid and safety belt, which is applied in the direction of belt tightener, etc., can solve the problems of reduced safety, high complexity, and high cost under special conditions, and achieve the effects of simple and reliable structure, improved safety, and large damping output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

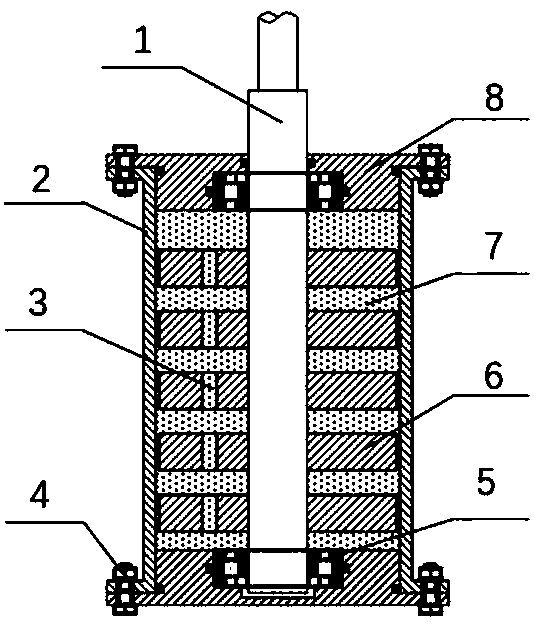

[0015] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention includes a rotating shaft 1, a cylinder wall 2, a normally open liquid channel 3, a bolt 4, a sealed bearing 5, a turntable 6, a shear thickening liquid 7, and a cover 8; the cylinder body is filled with the shear thickening liquid 7, One end of the rotating shaft 1 drives the turntable 6 to rotate in the cylinder body, and the other end extends out of the cylinder body to connect with the safety belt; the turntable 6 in the cylinder body is provided with a normal flow channel 3 to assist the distribution of the shear thickening liquid in the cylinder body uniform.

[0016] Working principle of the present invention:

[0017] When an external force is applied to the seat belt, the seat belt drives the rotating shaft at one end of the brake and the turntable to rotate relative to the cylinder body, and the side of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com