Aluminum alloy door and window production process

A technology of aluminum alloy doors and windows and production process, applied in the installation of window glass, wing frame and other directions, can solve the problems of difficult operation, unfavorable processing and production of doors and windows, trouble, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

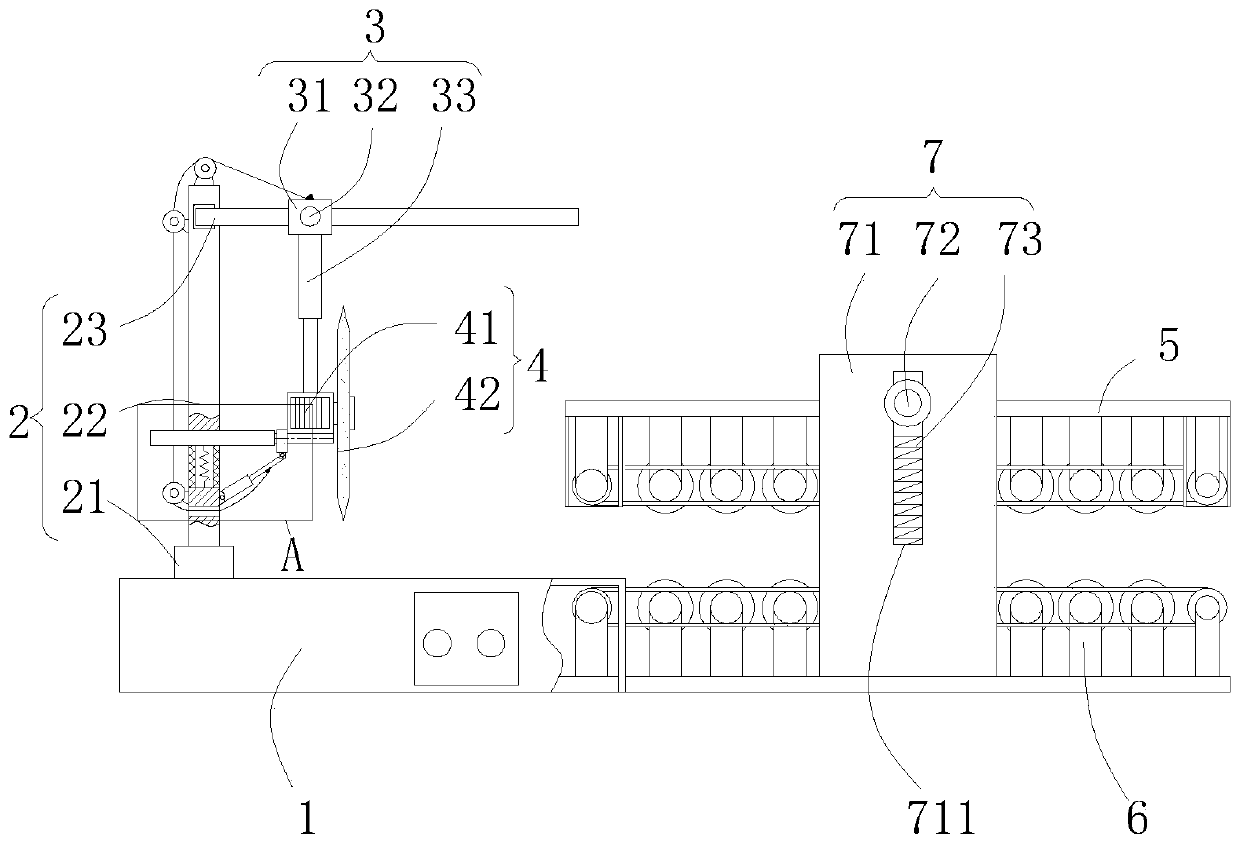

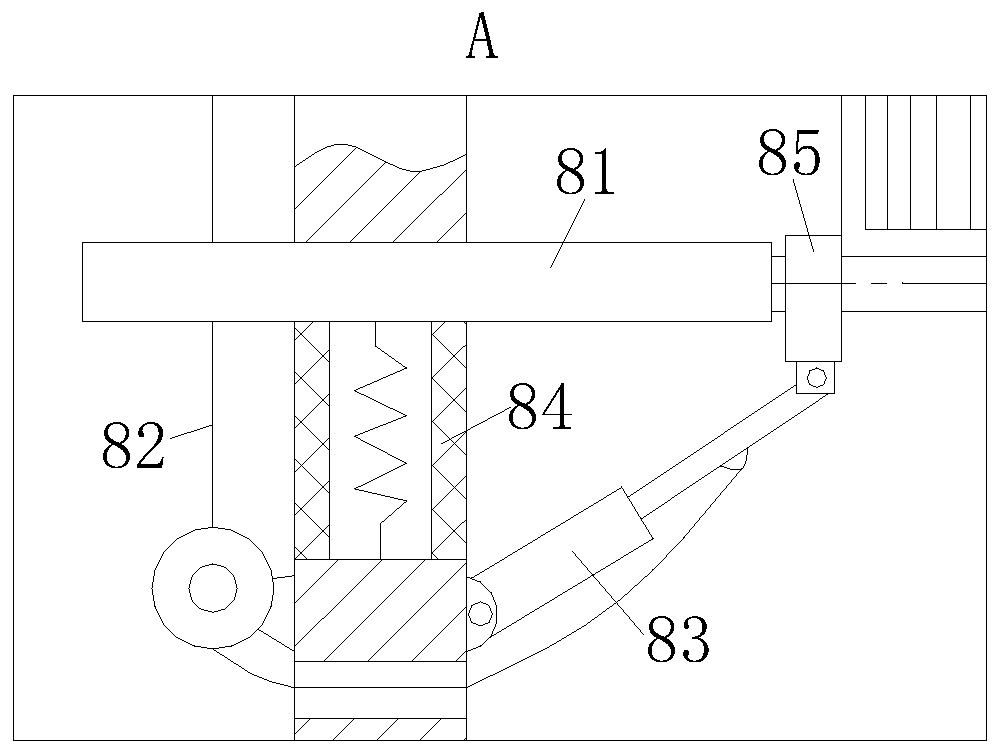

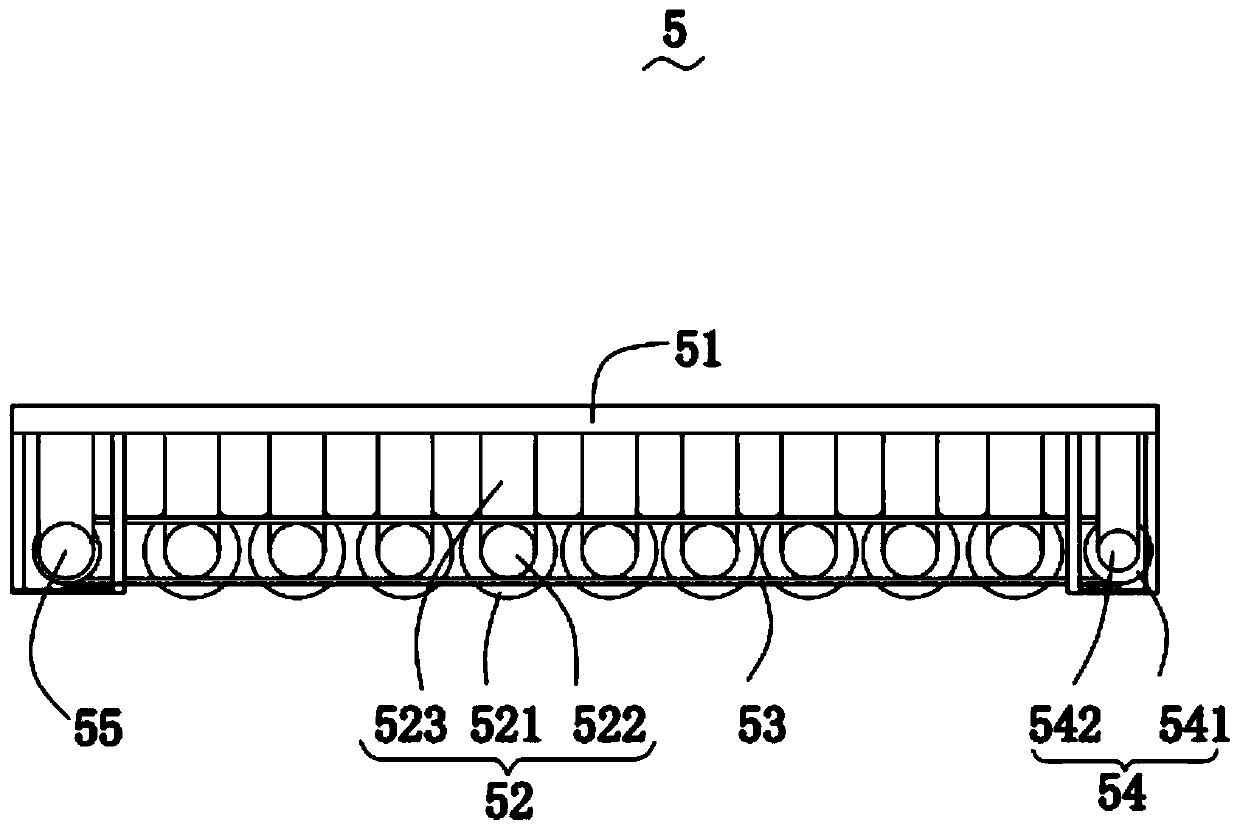

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] Such as Figure 1-5 As shown, a kind of aluminum alloy doors and windows production process of the present invention, this method comprises the following steps:

[0029] S1, using a cutting machine to cut strip-shaped aluminum profiles to form aluminum strips;

[0030] S2, fasten the aluminum strips cut in S1 with screws and glue to form an aluminum frame, but one side is not installed;

[0031] S3, install the glass on the aluminum frame, and then install the remaining aluminum strips;

[0032] S4, using glue to seal the contact between the glass and the aluminum alloy in S3;

[0033]The cutting machine adopted in this method comprises a substrate 1; the surface of the substrate 1 has a first chute 11, and the surface of the substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com