Garment ironing device

An ironing device and clothing technology, applied to textiles, papermaking, fabric surface trimming, etc., can solve problems such as unevenness, low ironing efficiency, and poor ironing effect, and achieve high efficiency and good ironing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

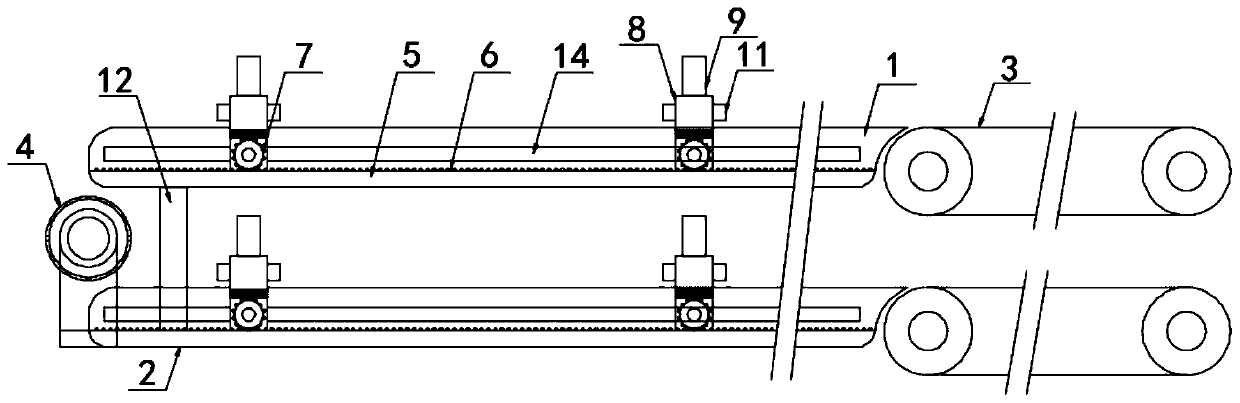

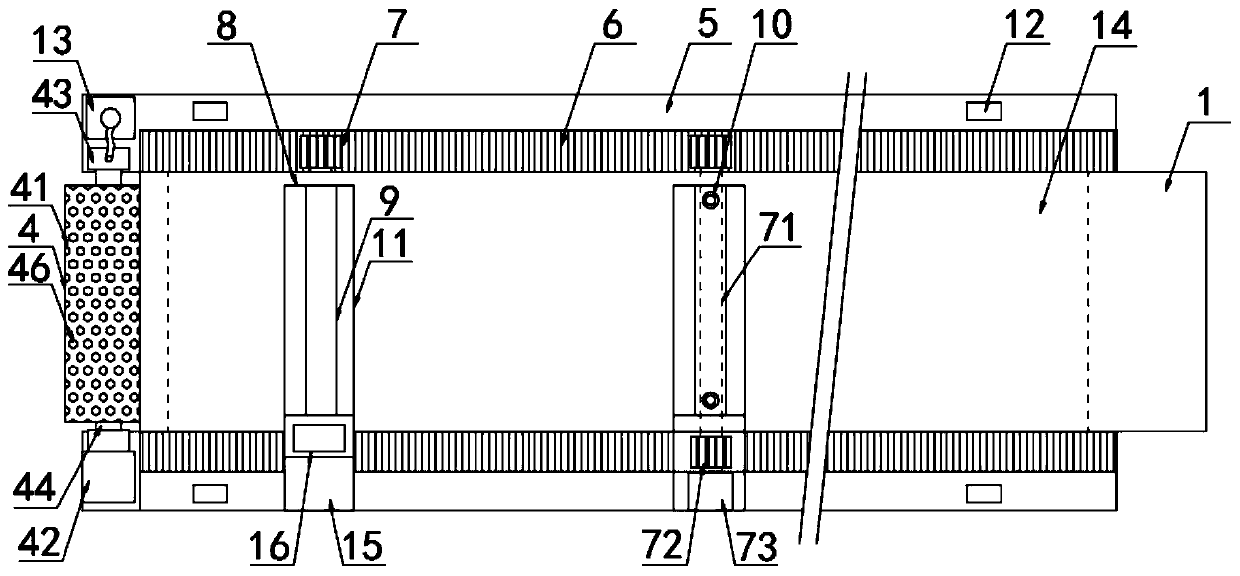

[0026] according to Figure 1-2 The clothes ironing device shown includes a front ironing board 1 and a back ironing board 2, the back ironing board 2 is arranged at the bottom of the front ironing board 1, and the front ironing board 1 and the back ironing board A belt conveyor 3 is provided on one side of the board 2, and the conveying direction of the two belt conveyors 3 is opposite. Mechanism 4, the front ironing board 1 and the back ironing board 2 are fixed with support plates 5 at the front and rear ends, the support plates 5 are provided with a gear groove 6, and the top of the gear groove 6 is provided with a driving mechanism 7. An ironing material suction mechanism 8 is provided on the top of the walking drive mechanism 7, and the ironing material suction mechanism 8 includes a steam transmission fixed rod 9, and electric cylinders 10 are fixed at both ends of the bottom of the steam transmission fixed rod 9, The bottom of the electric cylinder 10 is fixed with an...

Embodiment 2

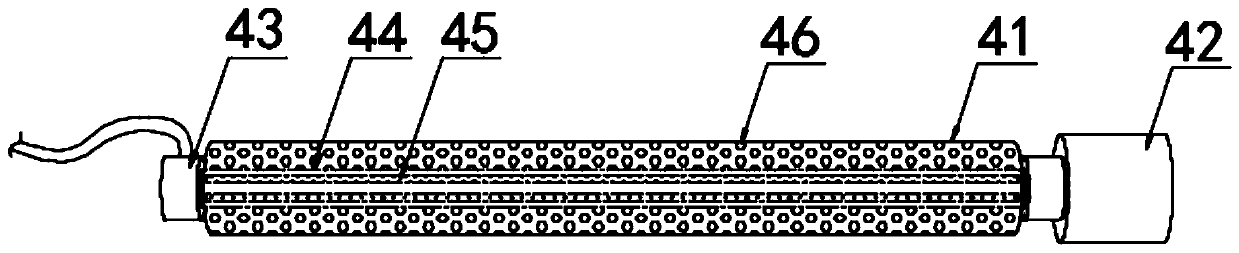

[0030] according to Figure 2-3 As shown in a garment ironing device, the material receiving and turning mechanism 4 includes a drum 41, and a rotating shaft 44 is fixed inside the drum 41. A servo motor 42 is provided at one end of the rotating shaft 44 and a bearing 43 is provided at the other end. A suction bin is provided between the rotating shaft 44 and the drum 41, the rotating shaft 44 is arranged in a tubular shape, and the outer wall is surrounded by a plurality of bar-shaped grooves 45 communicating with the suction bin, and the outer wall of the drum 41 is provided with multiple A receiving hole 46;

[0031] The bottom of the bearing 43 and the servo motor 42 are all fixedly connected to the support plate 5 through a bracket, and the support plate 5 corresponding to the rear side of the bearing 43 is provided with an exhaust fan 13, and the exhaust fan 13 is connected to the internal rotating shaft of the bearing 43 through the pipeline. 44 connected;

[0032] Wh...

Embodiment 3

[0038] according to Figure 6 A kind of clothing ironing device shown, two said belt conveyors 3 are driven by a set of gear transmission mechanism, and said gear transmission mechanism comprises driving gear 25 and driven gear 26, and said driving gear 25 and driven gear The gear 26 is meshed and connected, and the driving gear 25 is driven by a stepping motor 27, so that the conveying directions of the two belt conveyors 3 are opposite, and only one stepping motor 27 is needed to save mechanical costs and electric energy. Conveyor 3 delivers consistent and precise steps.

[0039] The working principle of the present invention:

[0040] Refer to the attached Figure 1-3 , during use, the tidied flat clothes are transported to one end of the front ironing board 1 through the belt conveyor 3, at this time, the traveling drive mechanism 7 drives the ironing suction mechanism 8 to move back and forth above the front ironing board 1, and the suction pump 16 work, absorb and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com