Weft processing process and weft accumulator for using same to improve process

A technology of processing technology and weft thread, which is applied in the field of weft thread processing technology and its weft storage device using modified technology, can solve the problems of limited surface flatness of cloth, and achieve the effects of reducing napping, improving flatness, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]The treatment process of the weft before weaving:

[0045] S1. equipment preparation: provide the thread ball of braided thread and the weft feeder body for storing braided thread, and be provided with wetting device between the wire inlet end of weft feeder body and the thread ball, in the weft feeder body An ironing device is provided at the outlet end;

[0046] S2. Wetting treatment: after passing the braided thread on the thread ball through the wetting device, the braided thread contains water, and the braided thread is stored in the weft feeder body;

[0047] S3. Ironing treatment: the braided thread in the weft feeder body passes through the ironing device, and the ironing device squeezes and heats the braided thread.

Embodiment 2

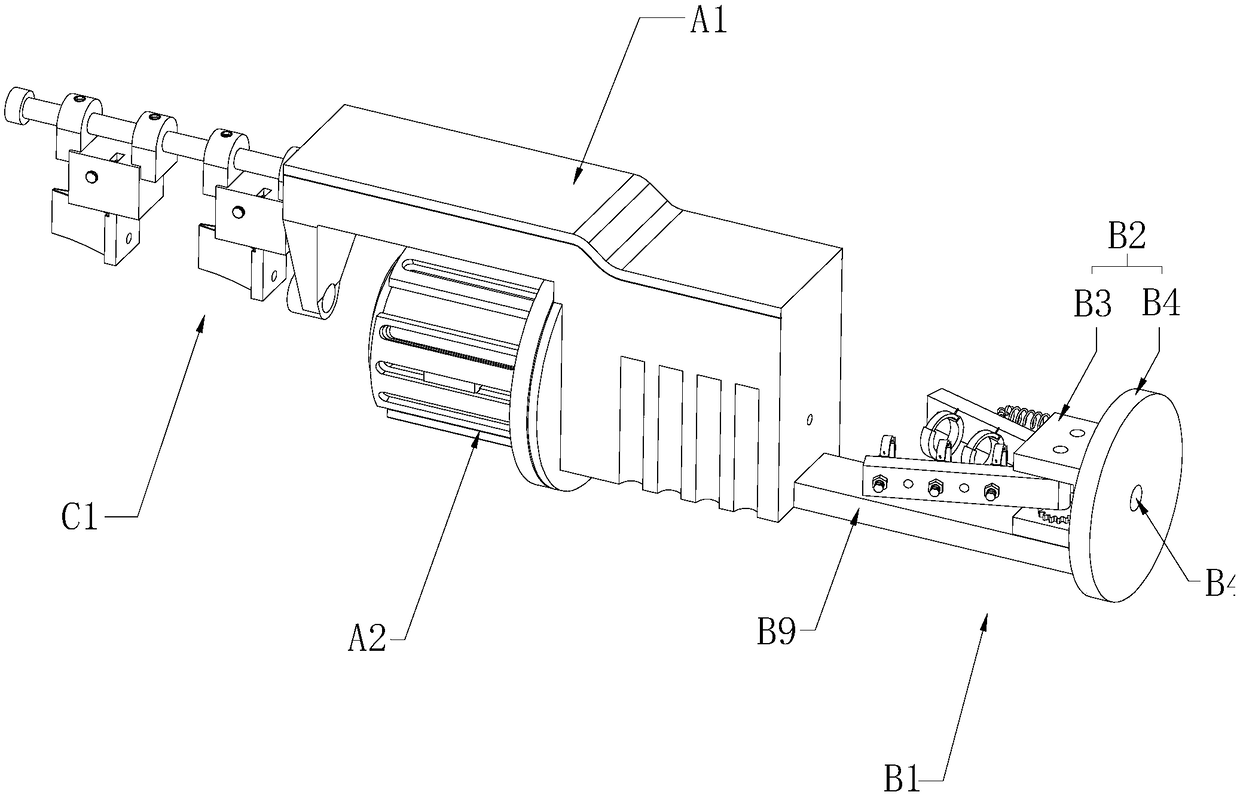

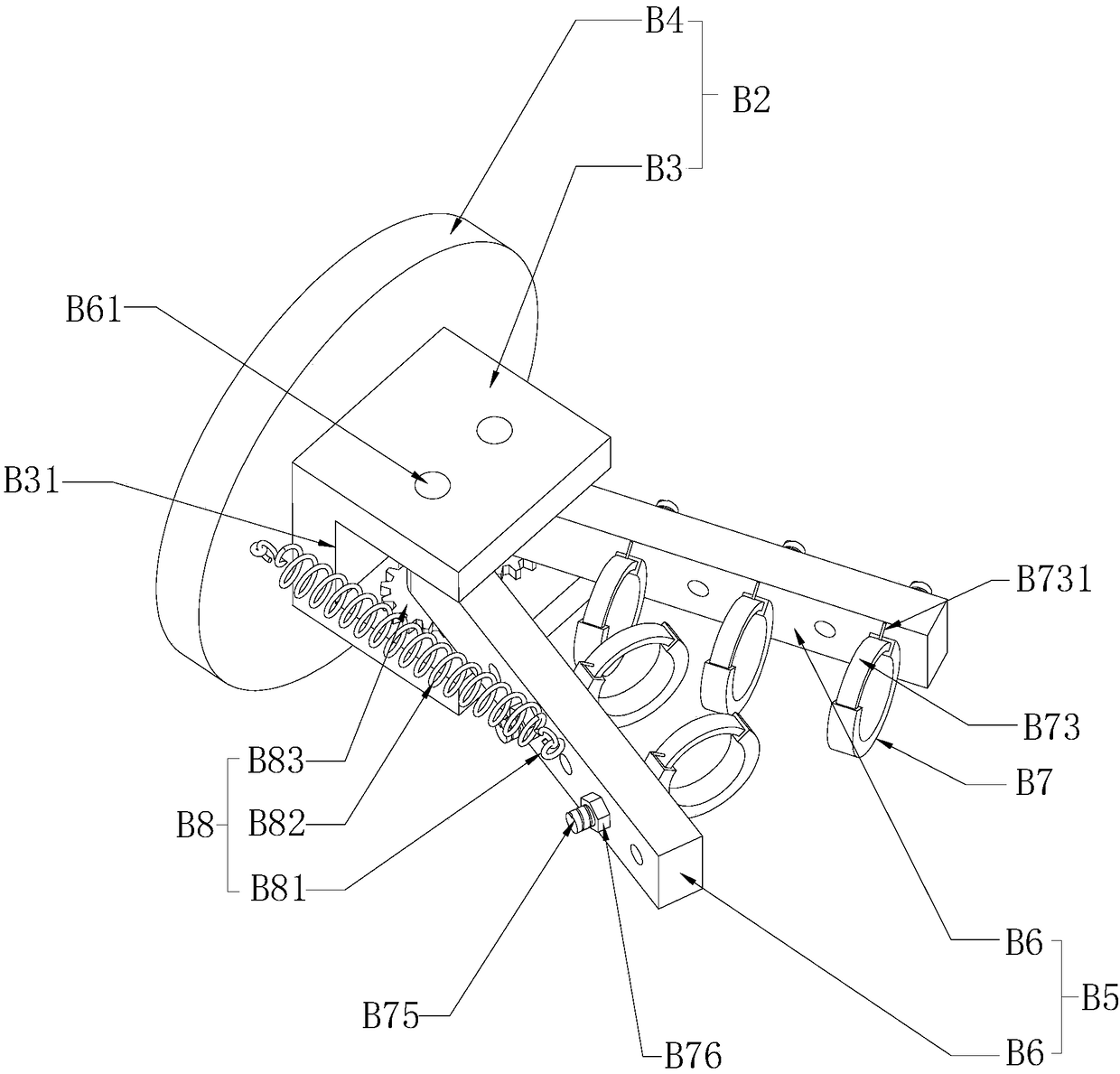

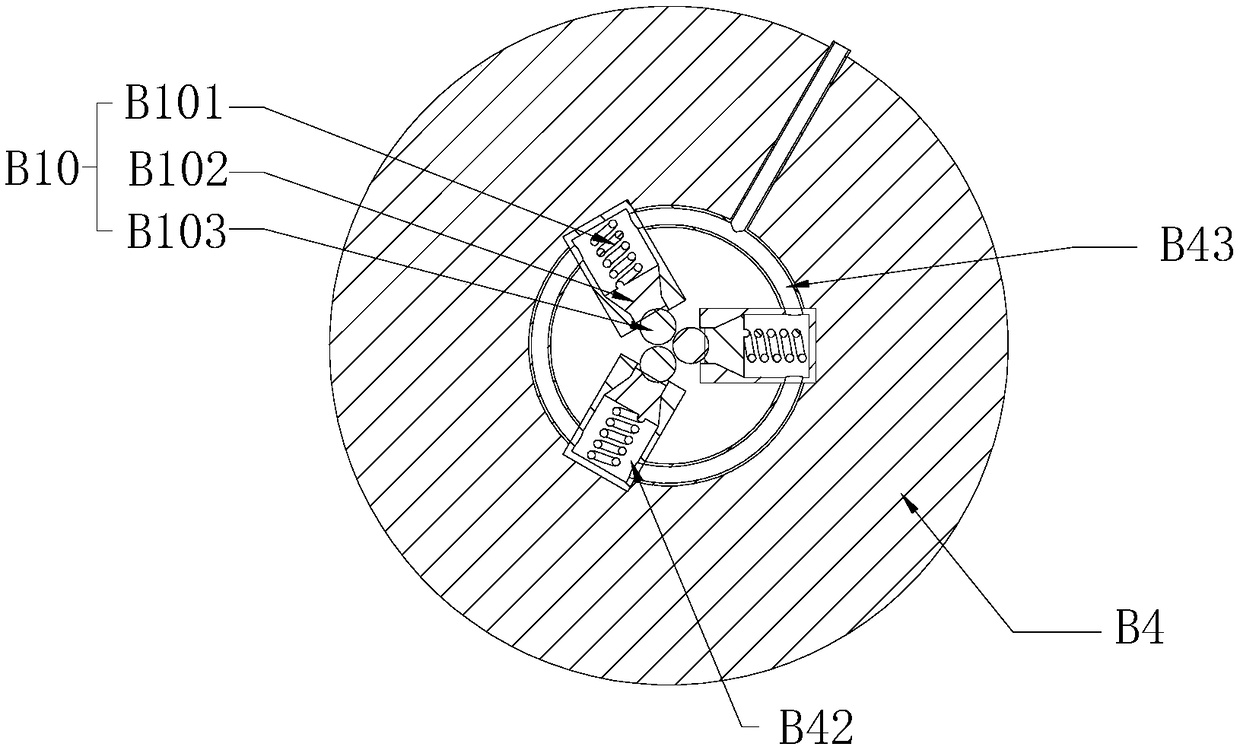

[0049] Such as figure 1 As shown, a weft storage device includes a frame A1 and a weft feeder body A2. The weft feeder body A2 is fixed on the frame A1 for storing braided threads. A wetting device B1 and an ironing device C1 are respectively provided; the braided thread on the thread ball passes through the wetting device B1, the weft feeder body A2 and the ironing device C1 in sequence, and the braided thread is stored in the weft feeder body A2. When pulling the braided wire, the wetting device B1 provides moisture to the braided wire, making the braided wire wet with water, increasing the smoothness of the braided wire during pulling, and the moisture can effectively reduce the phenomenon of braided wire pulling and improve the transmission of the braided wire The smoothness during the process, and then when the braided thread passes through the ironing device C1, the ironing device C1 squeezes and heats the braided thread, squeezes and irons the braided thread until it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com