Temperature-controlled automatic energy-saving water mixing valve

A technology of temperature-controlled water mixing valves, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as low efficiency, waste of water resources, waste of cold and hot water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the drawings and embodiments:

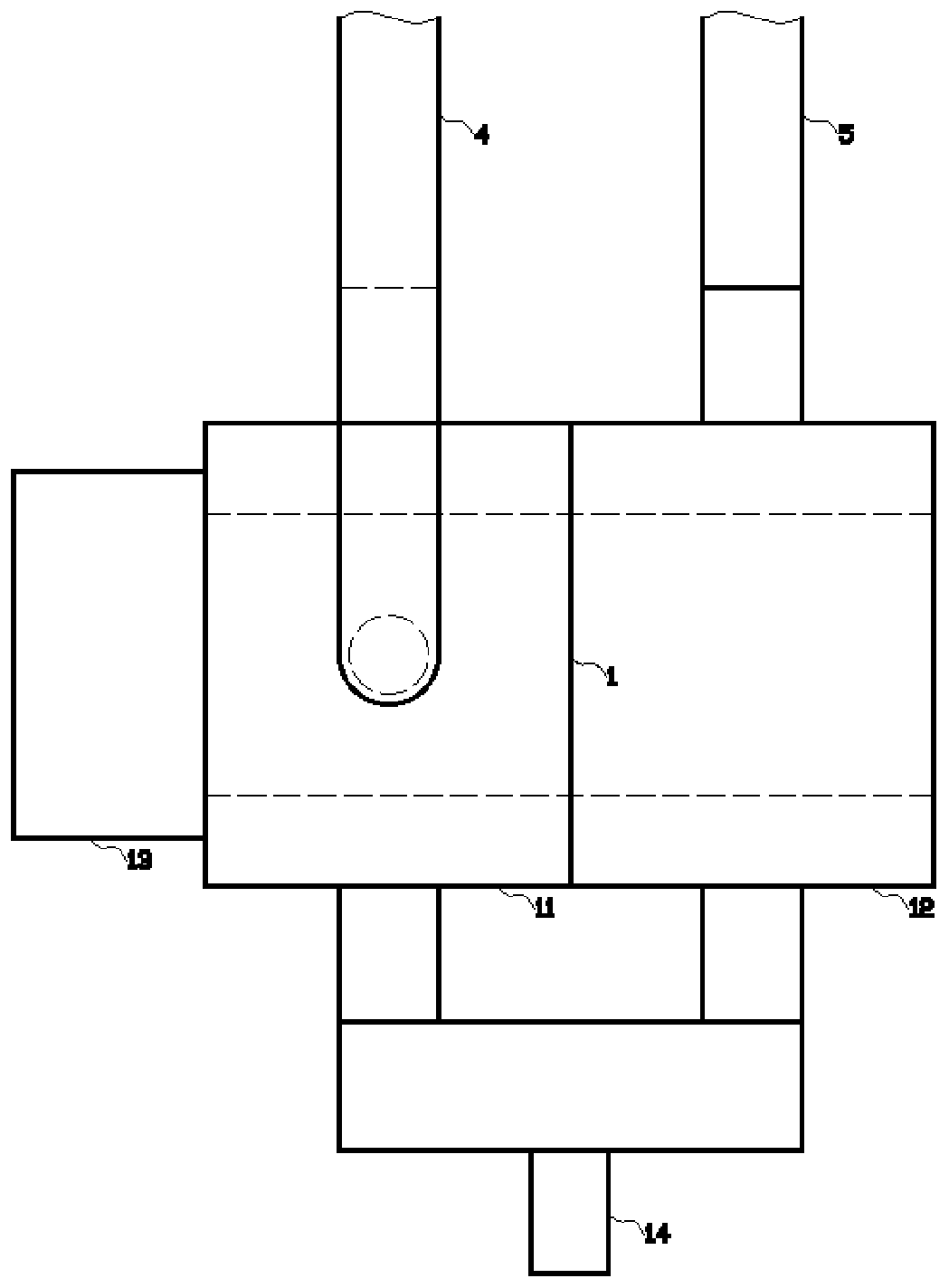

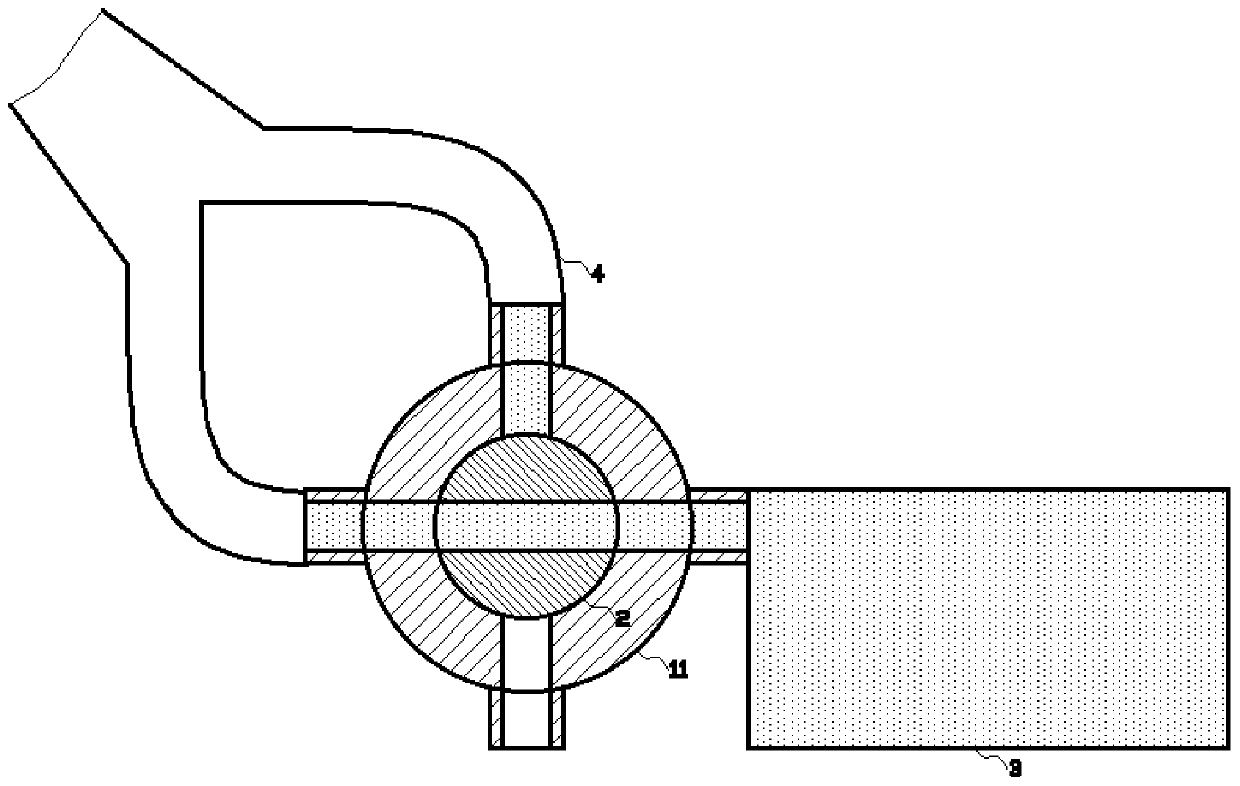

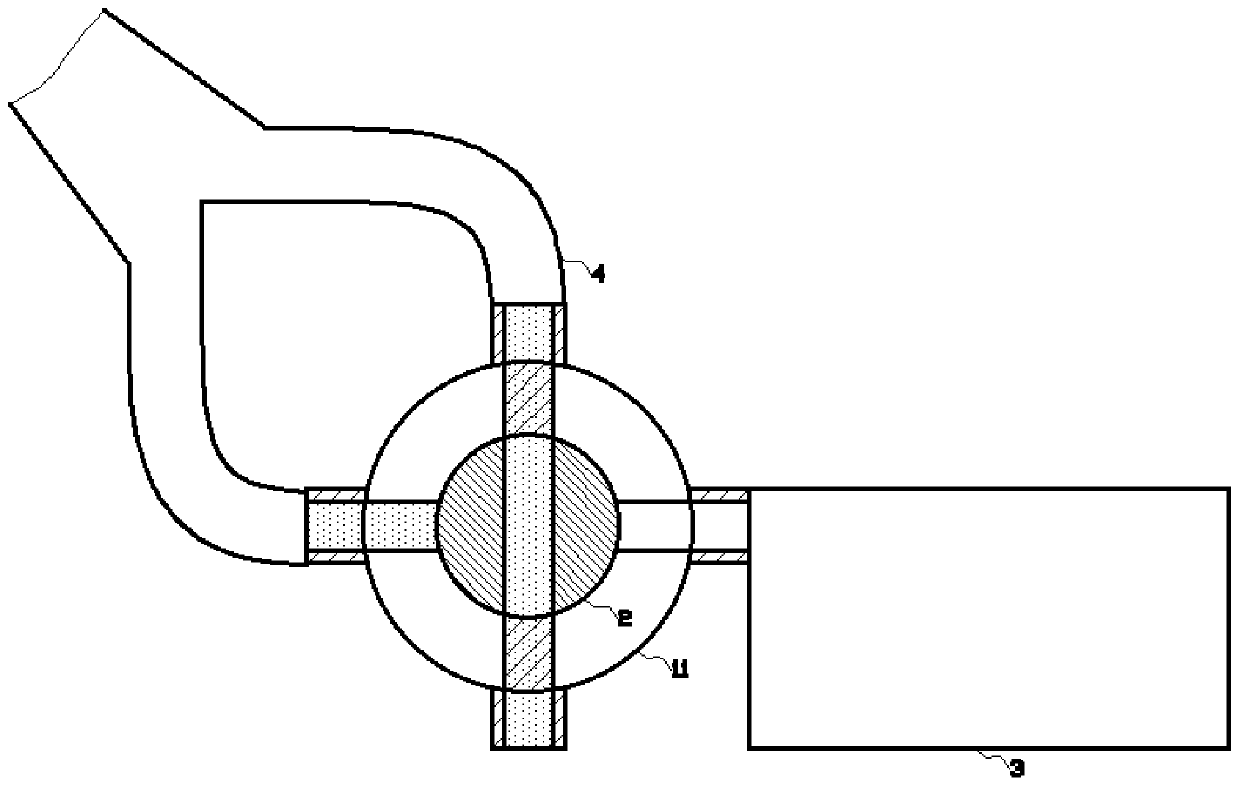

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the example, the temperature-controlled automatic energy-saving water mixing valve detects the water temperature of the hot water pipe, so that when the cold water is discharged in the early stage, the cold water is drained to the storage tank for storage, and when the water temperature rises, it is opened at the same time The opening of the cold and hot water pipe flows out through the water mixing valve to obtain warm water. It includes a water mixing module 1, a regulating module 2, a water storage tank 3, a hot water pipe 4 and a cold water pipe 5; the shape of the water mixing module 1 In a cylindrical shape, the water mixing module 1 is provided with a transverse cylindrical cavity inside, the water mixing module 1 includes a cold water valve 12 and a hot water valve 11, the cold water valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com