Heat dissipation control method of heat dissipation system for projector

A heat dissipation system and control method technology, applied in the direction of instruments, optics, projection devices, etc., can solve the problems of affecting movie viewing experience, limited heat dissipation space, low heat dissipation efficiency, etc., and achieve the elimination of the influence of fan noise, low noise and high efficiency heat dissipation , the effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

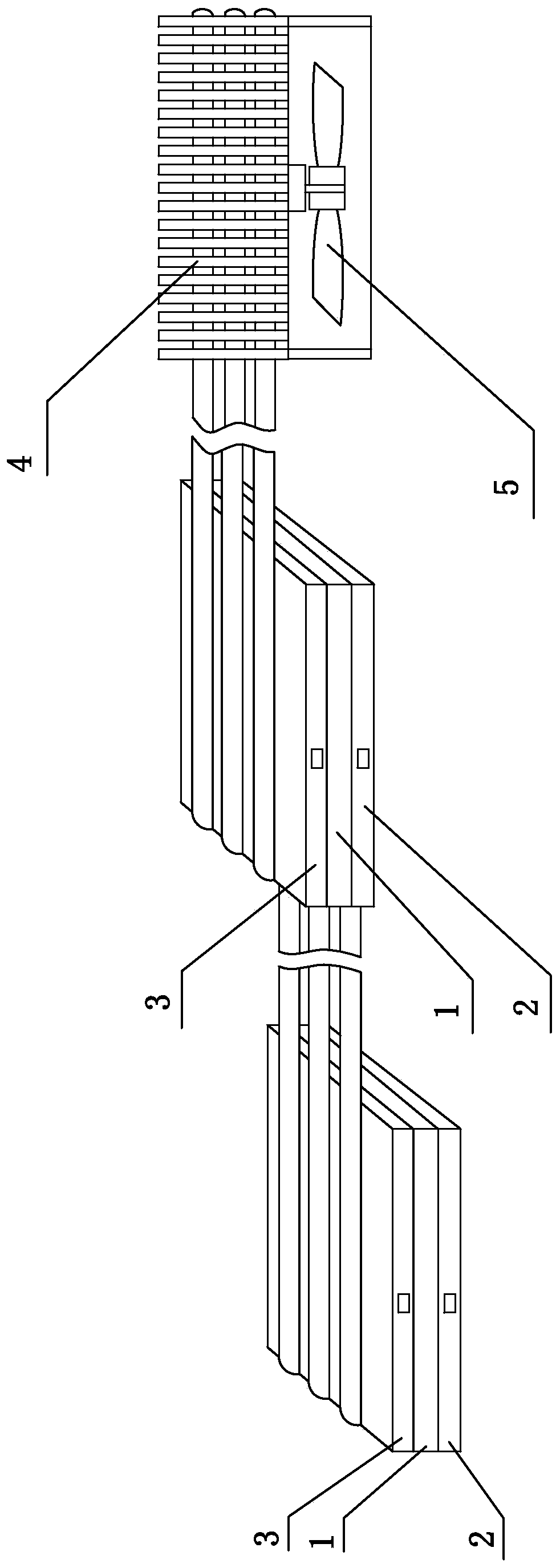

[0019] like figure 1 As shown, the heat dissipation system for a projector includes a heat conduction temperature measuring device located at the front end and the middle of the system and a heat dissipation device located at the end of the system; The cold end heat conduction block 2 and the hot end heat conduction block 3 are composed of the cold end heat conduction block and the hot end heat conduction block; The end heat conduction block 3 is provided with a groove for embedding a temperature sensor to accommodate the temperature sensor and lead out its power supply electrodes. A good heat conduction contact is required between the temperature sensor and the heat conduction block where it is located; The end heat conduction block 3 is thermally connected to the cold end heat conduction block 2 of the heat conduction temperature measuring device in the middle of the system through heat conduction tubes; according to different application spaces, different heat conduction tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com