Rubber plug notch automatic line

An automatic line and incision technology, applied in metal processing and other directions, can solve the problems of uncertainty of manual operation, difficult to guarantee quality, and large market consumption, so as to reduce labor intensity, improve production efficiency, and realize the effect of incision operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now, the present invention will be further described in detail in conjunction with the accompanying drawings and preferred embodiments.

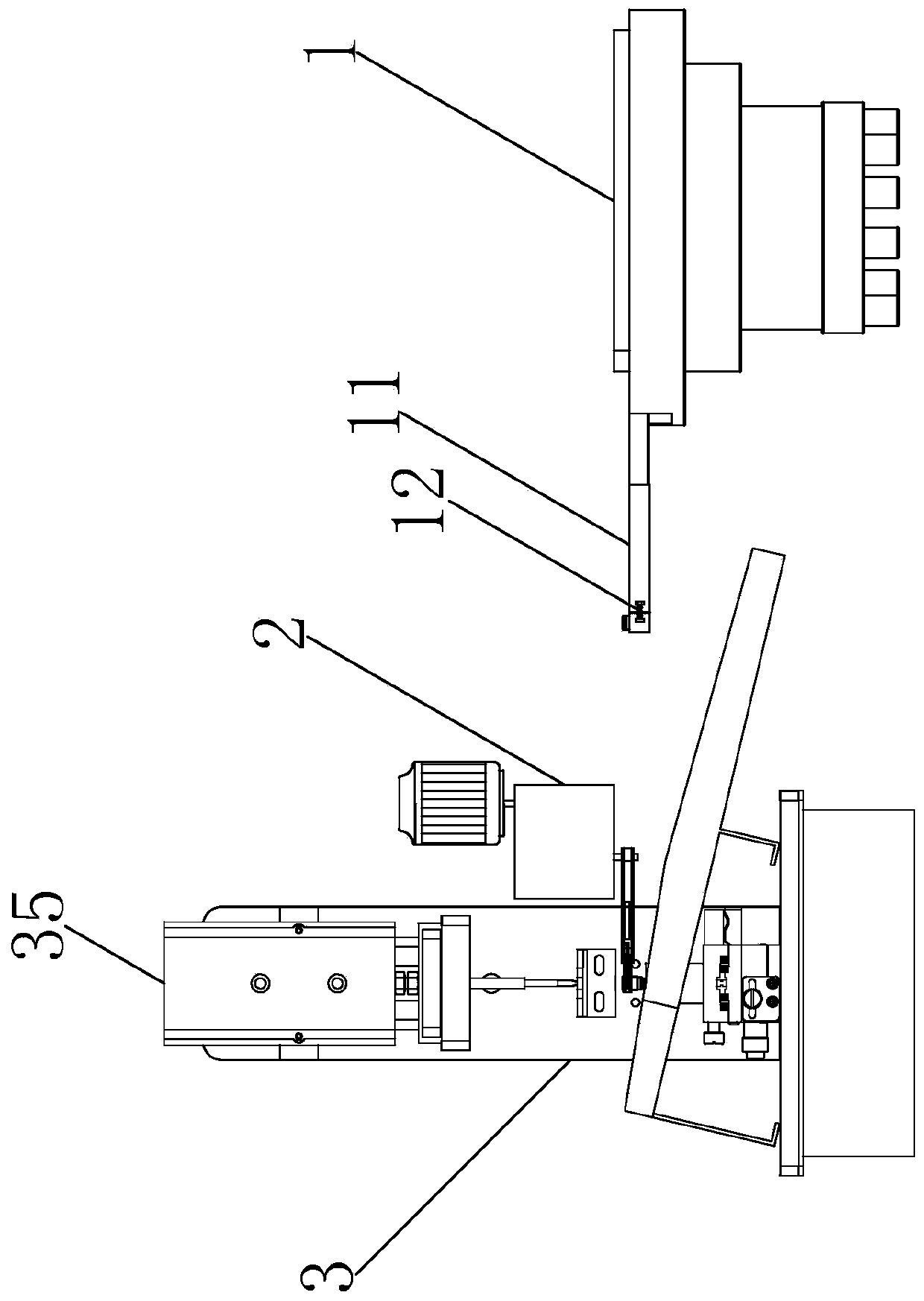

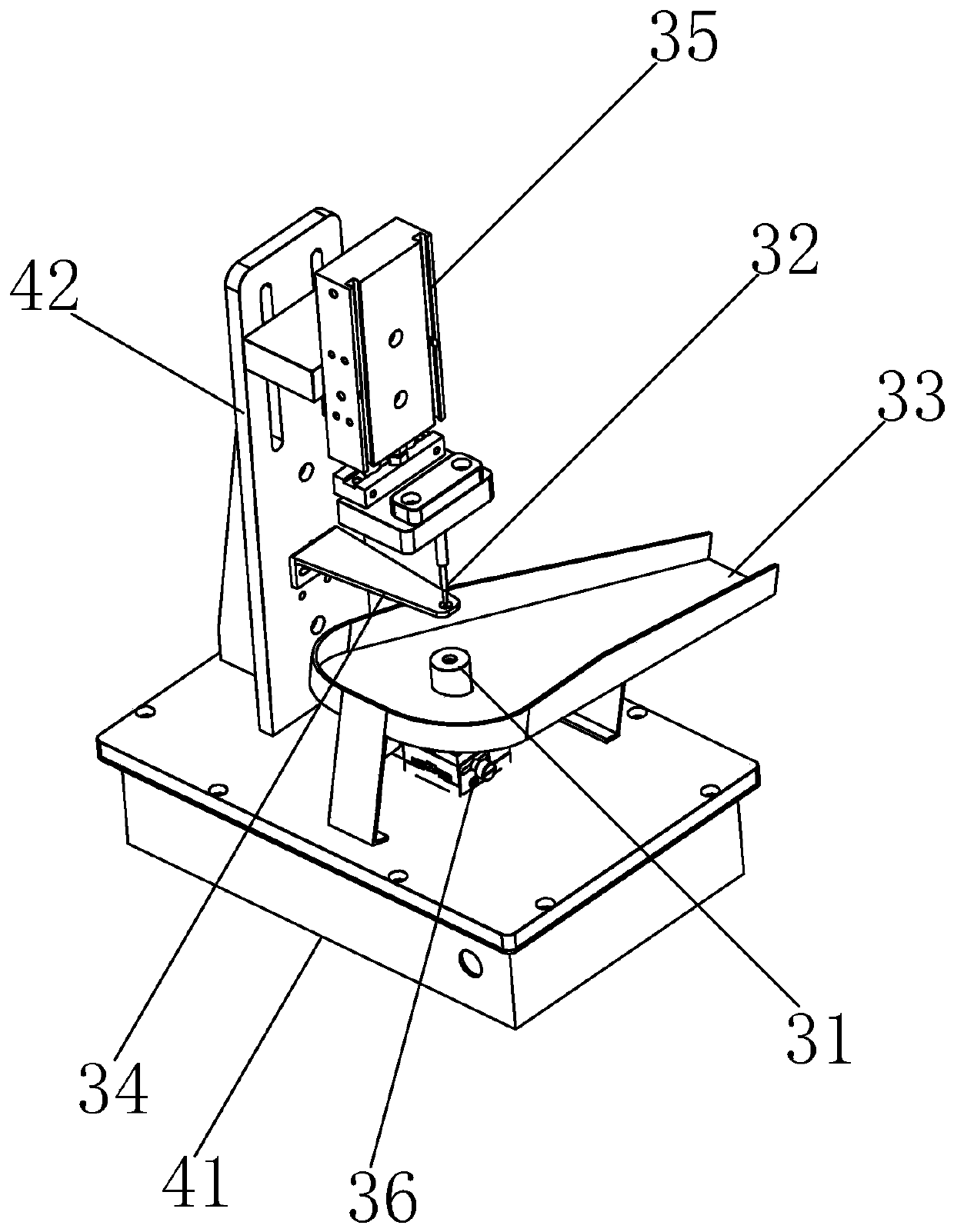

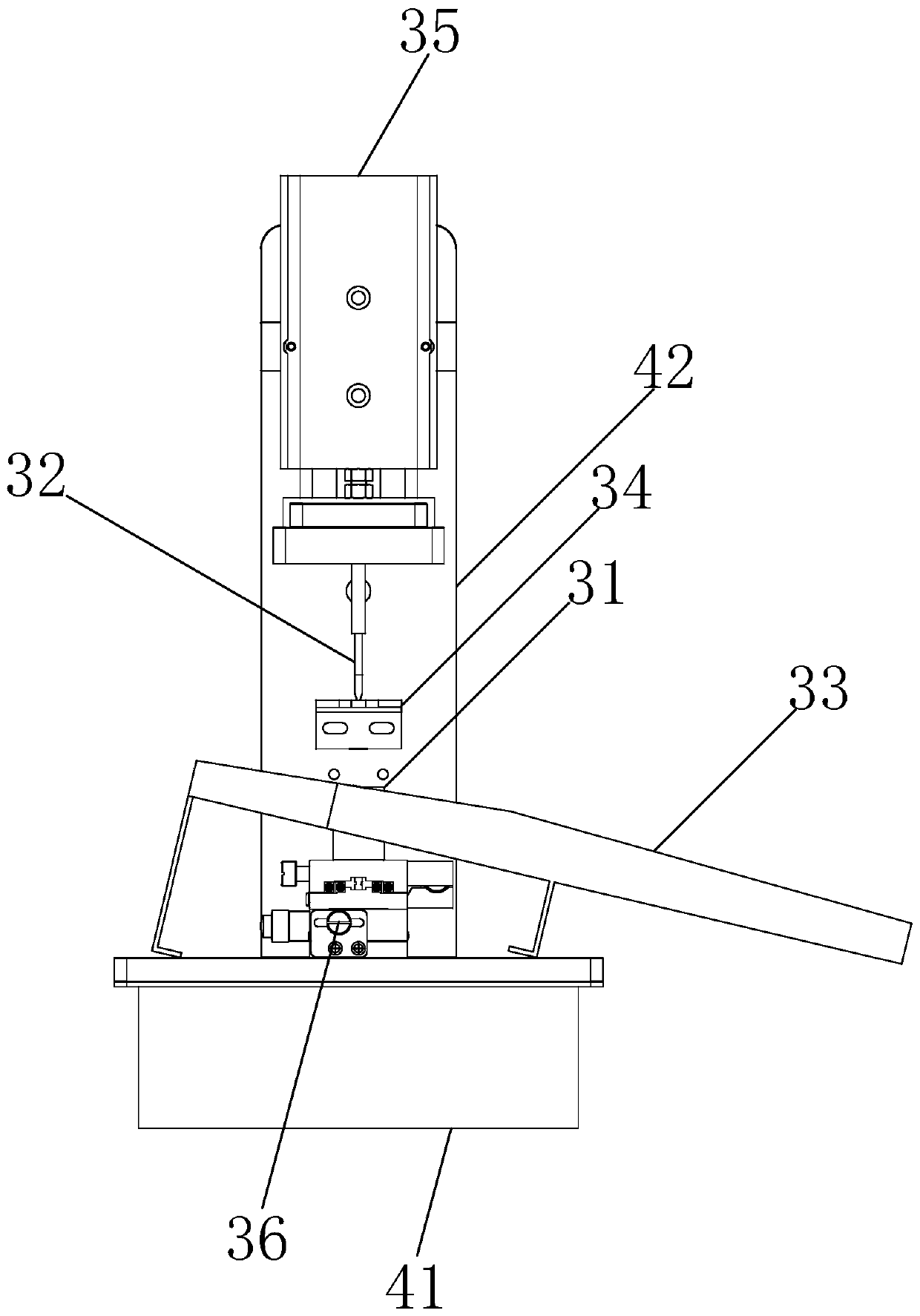

[0021] Such as figure 1 The shown automatic line for rubber stopper cutting includes a vibrating plate 1, a transfer assembly 2 and an incision assembly 3, and the output end of the vibrating plate 1 is provided with a feeding assembly 11. The specific method is that the vibrating plate 1 feeds, and the The rubber plugs are transported to the feeding assembly 11 in an orderly manner. The incision assembly 3 includes a mold 31 for placing the rubber plugs and a cutter 32 that can move close to and away from the mold 31 vertically. The transfer assembly 2 transfers the rubber plugs on the feeding assembly 11. Transfer to the mold 31, and the cutter 32 moves downward to cut the end of the rubber plug, so as to realize the automatic cutting operation, improve the production efficiency and reduce the labor intensity.

[0022] As a further...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap