Novel gas and liquid pump

A liquid pump, a new type of technology, applied in the field of gas-liquid pumps, can solve the problems of one-way rotation workmanship, large mechanical resistance, high manufacturing cost, etc., and achieve the effect of minimum working resistance, simple structure, and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

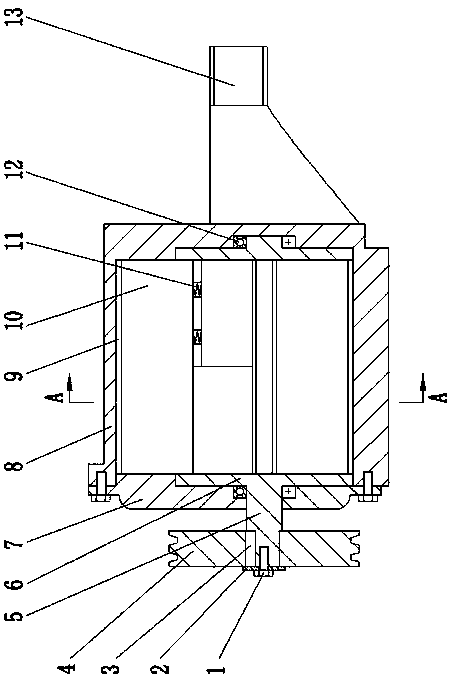

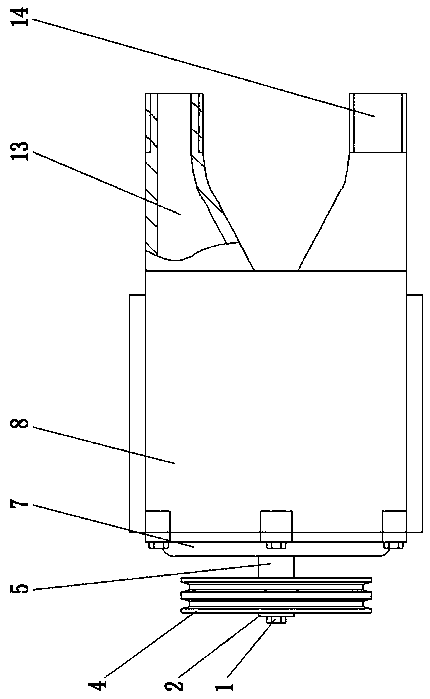

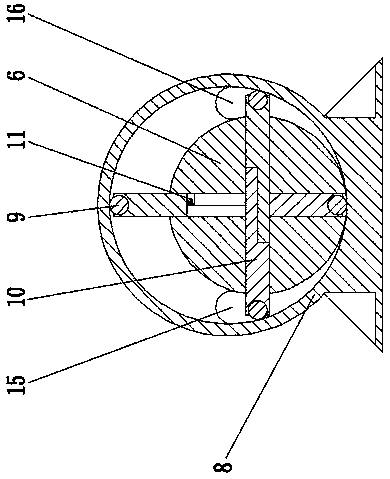

[0027] The specific embodiment of the present invention is, with reference to figure 1 , figure 2 and image 3 , the pump casing 8, the pump core 6, the blade 10, the spring 11, the pump cover 7, the pulley 4, the pump casing 8 is connected to the pump cover 7, the pump core 6 is arranged in the pump casing 8, and The mandrel 5 of the pump core 6 is connected to the bearing 12 of the pump casing 8 and the pump cover 7, the pump core 6 is slidably connected to the blade 10, and the blade 10 is connected to the needle roller 9 in rotation, and the pump core 6 is connected to the pump core 6. There are springs 11 between the blades 10 described above, and the pump core 6 flat key 3 is connected to the pulley 4, the bolt 1 and the gasket 2 are fixed, refer to Figure 11 , the pump casing 8 is connected to the inlet liquid passage 13 and the outlet liquid passage 14, and the inlet liquid passage 13 and the outlet liquid passage 14 are connected to the inlet liquid port 15, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com